Novel profile combined sponge suction cup

A combination and profile technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of uneven deformation of sponge pads, poor adsorption effect, high production costs, etc., to achieve beautiful and regular appearance, strong working stability, and production The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

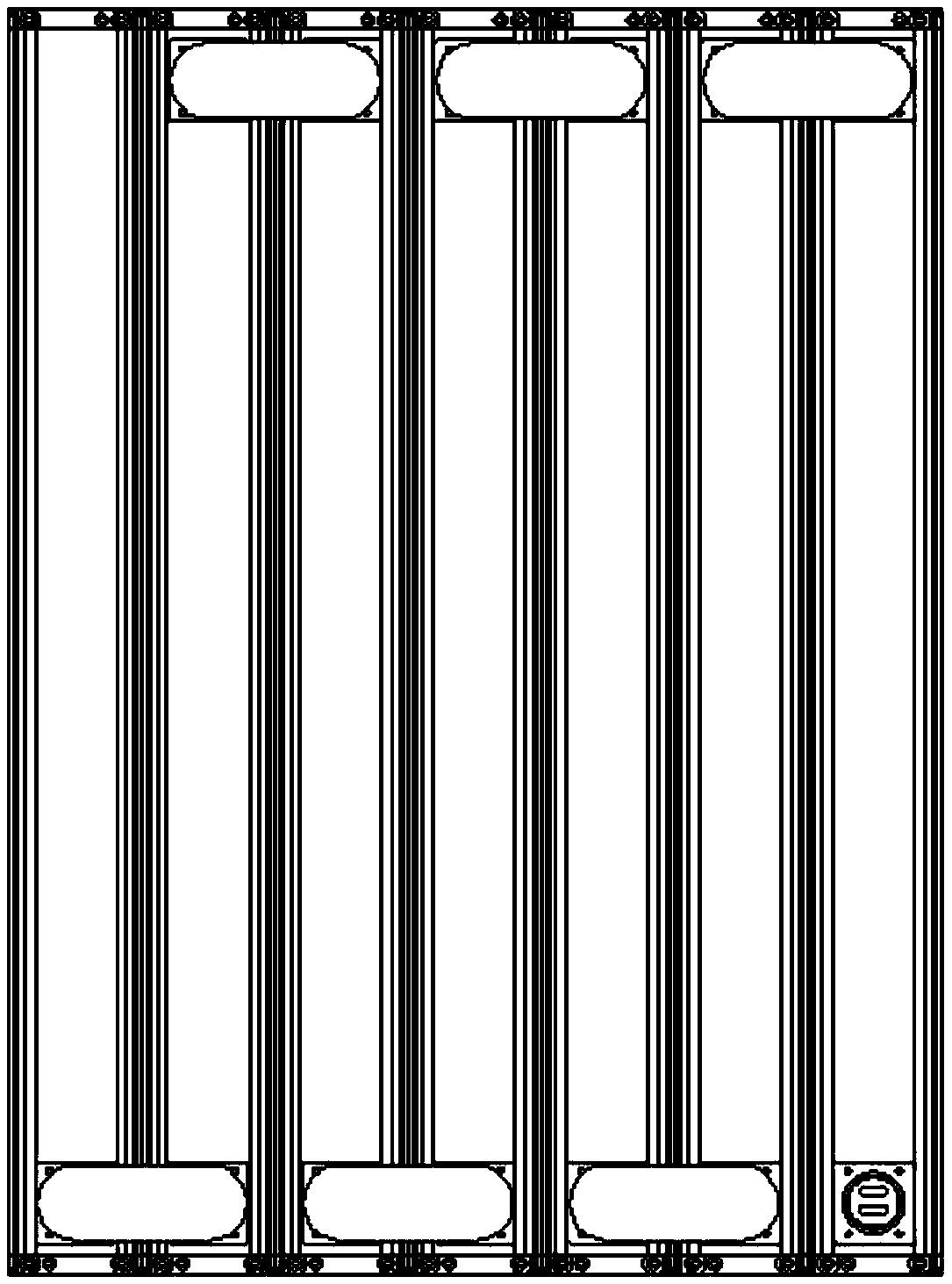

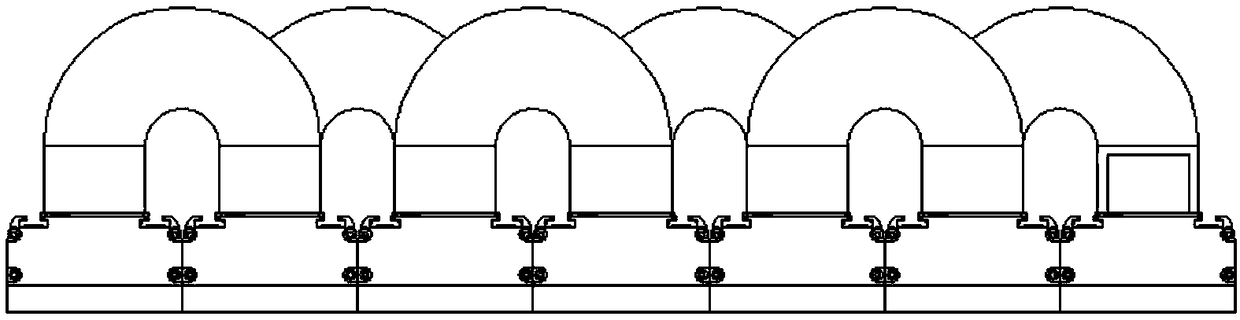

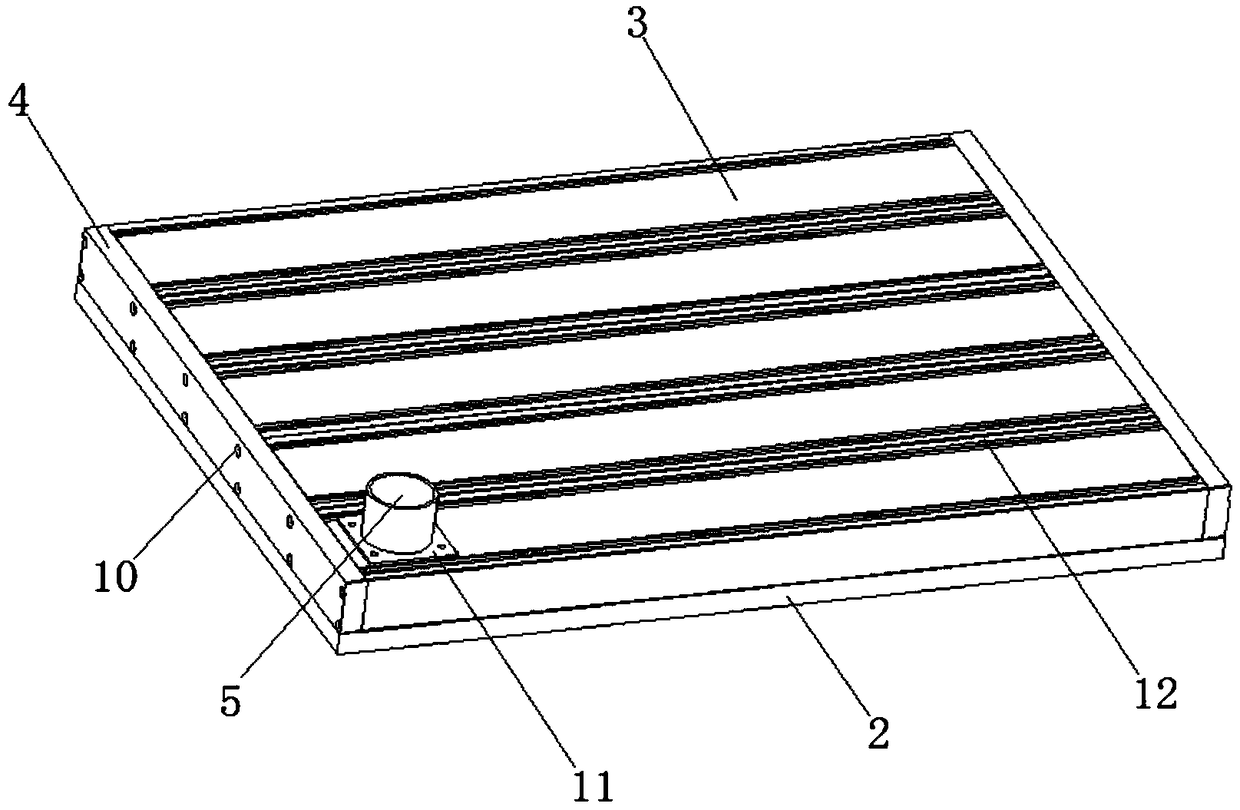

[0019] combine image 3 and Figure 4 , this embodiment is a new profile combined sponge suction cup, including a vacuum chamber 1 and an adsorption sponge layer 2 covering the lower wall of the vacuum chamber 1, the vacuum chamber 1 includes an aluminum profile main body 3 and a pair of end covers 4, A pair of end caps 4 are respectively covered and fixed on the two ends of the aluminum profile main body 3 to form a closed chamber inside the aluminum profile main body 3. The upper wall of the aluminum profile main body 3 is provided with a vacuum port 5, and the adsorption sponge layer 2 is provided with a number of uniform Distributed adsorption holes 7.

[0020] Such as Figure 5 As shown, the lower wall of the aluminum profile main body 3 is provided with a number of evenly distributed air holes 6, and the aluminum profile main body 3 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com