New type safety valve

A safety valve, a new type of technology, applied in safety valves, safety arrangements, balance valves, etc., can solve the problems of valve opening pressure setting drift, displacement medium temperature increase, strong thermal shock, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

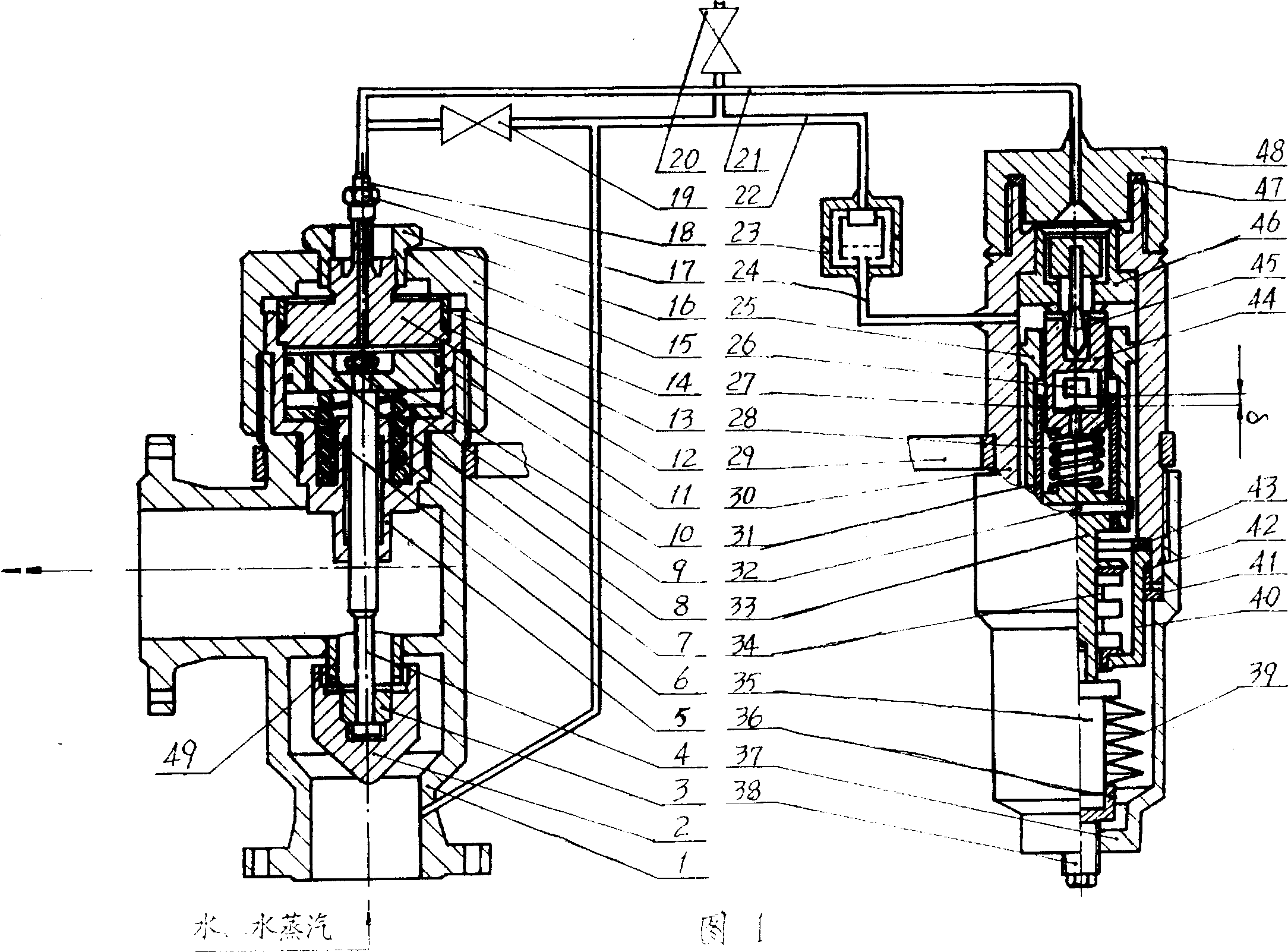

[0024]The structure of the new safety valve provided by the present invention is shown in the left part of Fig. 1, the main valve seat [49] is welded on the main valve body [1], and the main valve disc [2] is covered on the main valve seat [ 49] on. The lower end of the main valve stem [4] is screwed in by the screw plug [3] to connect it to the main valve disc [2], the upper end passes through the piston [8], and the nut [10] is used, and the anti-loosening spring washer [9] is added. ] screwed onto the piston [8]. The piston [8] is placed in the cylinder liner [5]. The main valve preload spring [7] is placed in the groove of the cylinder liner [5], the upper end is in contact with the piston [8], and the lower end is in contact with the bottom of the groove of the cylinder liner [5], and is compressed to a certain extent. The force generated by the compression is transmitted to the main valve disc [2] through the piston rod [4], so that the main valve disc [2] generates an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com