Waste battery classifying device

A sorting device and waste battery technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of no convenient disassembly and push unloading, no movement and stable installation, no vibration unloading, etc., to achieve regulation Convenience, ease of vibration classification, and the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

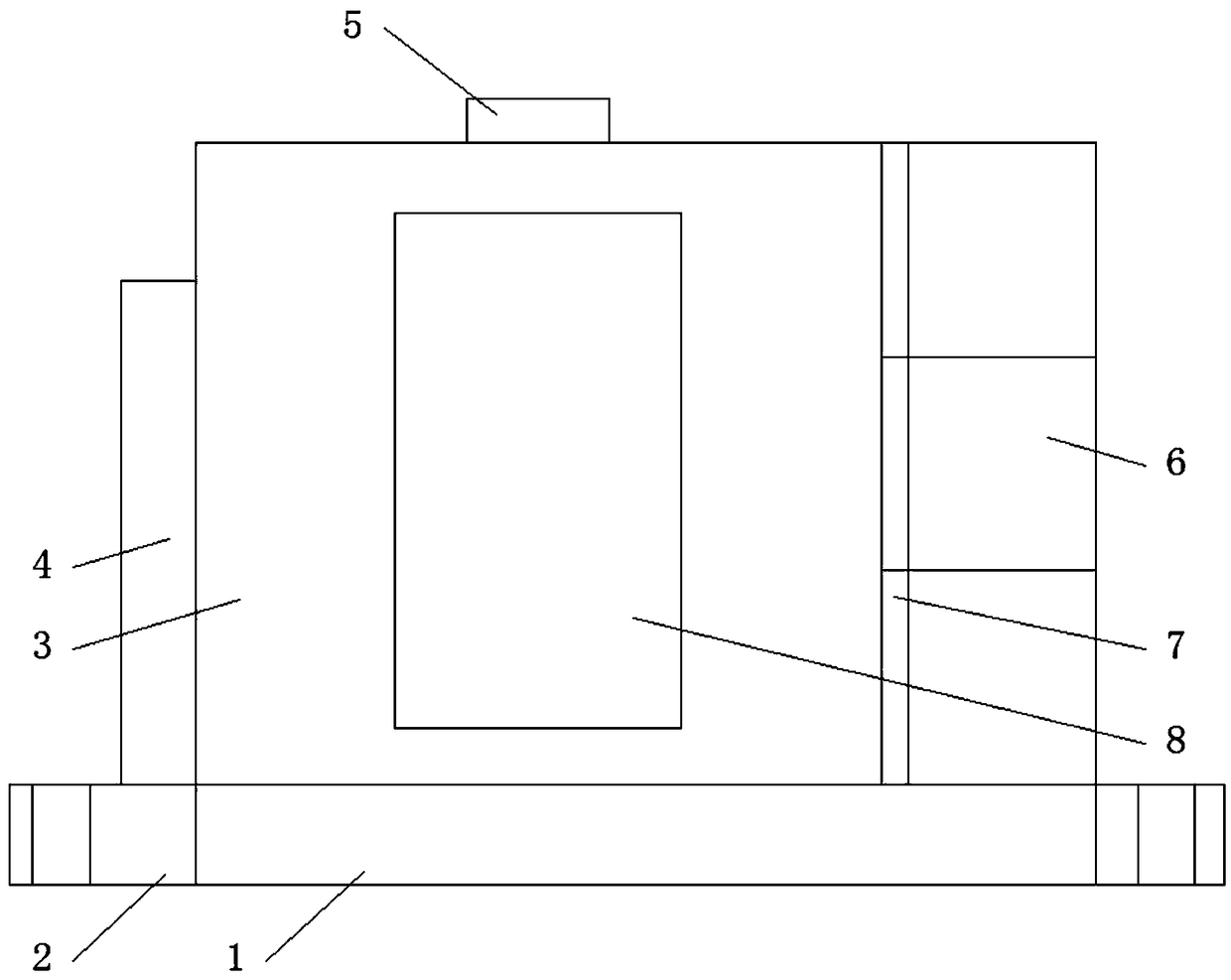

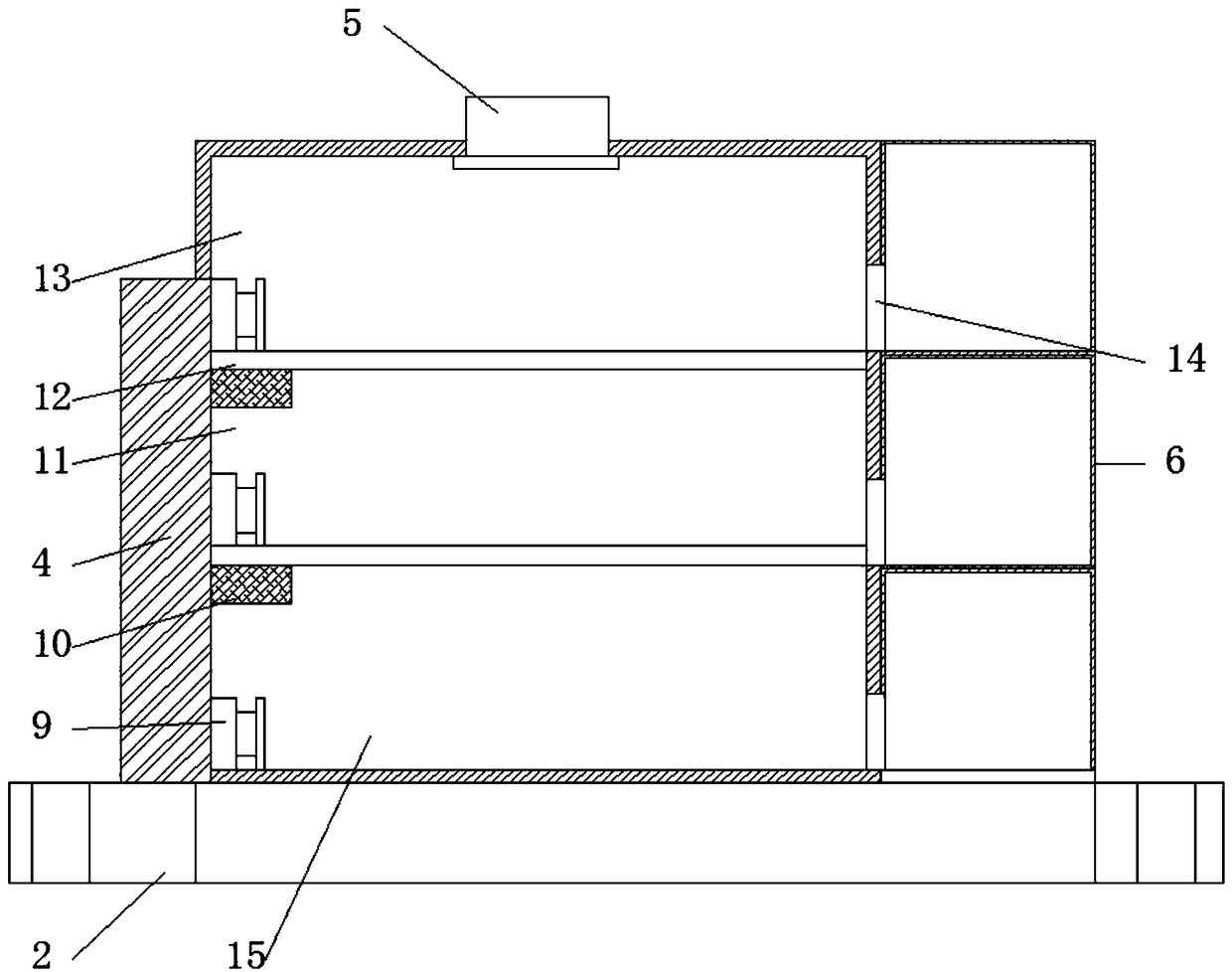

Image

Examples

Embodiment 2

[0023] On the basis of Example 1, the anti-slip mat is made of the following components in parts by weight: 100 parts of polyisoprene rubber, 20 parts of calcined kaolin powder, 3 parts of active calcium, 5 parts of vulcanizing agent, and 3 parts of granular sulfur 4 parts of modified zeolite powder, 2 parts of polypropylene glycol diglycidyl ether, 2 parts of rose essential oil, 3 parts of nano-silica, 1 part of tetrahydrophthalic anhydride; good anti-slip effect, wear-resistant and tear-resistant.

[0024] The processing method of above-mentioned modified zeolite powder is as follows:

[0025] (1) Roast zeolite powder of 80-120 mesh at 280-350° C. for 2 hours, and take it out after natural cooling to normal temperature;

[0026] (2) Weigh 50kg of cooled zeolite powder and 0.5kg of silicone oil, mix them evenly, heat up to 115-125°C, and heat-preserve and grind for 30 minutes;

[0027] (3) Naturally cool the above-mentioned ground material to 45-55°C, then add 200kg of magne...

Embodiment 1

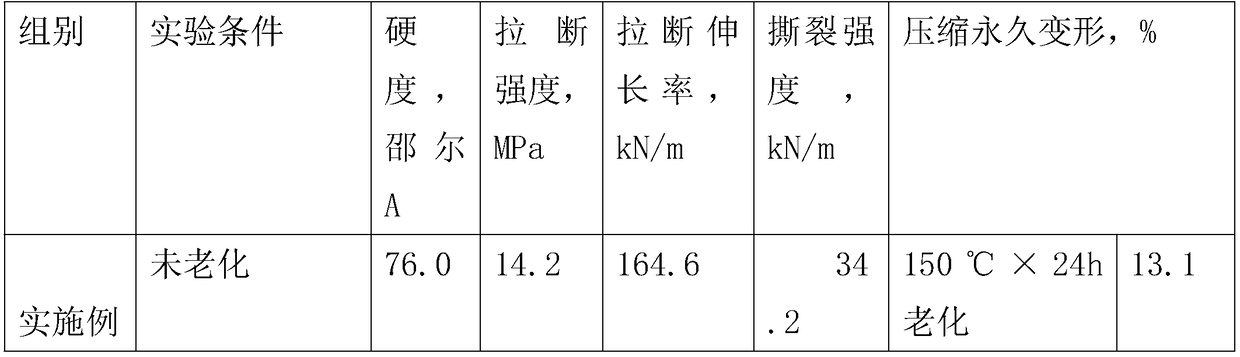

[0032] The physical performance parameter of anti-slip pad in embodiment 1 is as follows:

[0033]

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com