In-situ precipitation preparation method for geopolymer fluorine removal agent and application

A geopolymer and in-situ precipitation technology, which is applied in the direction of alkali metal compounds, chemical instruments and methods, water pollutants, etc., can solve problems that are difficult to apply to column separation technology, complicated preparation process, high raw material cost and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of tetravalent cerium salt solution: 6gCeCl 3 ·7H 2 O was dissolved in 90g of distilled water, and then 1.2g of 30% H 2 o 2 Add it dropwise to the above solution while stirring, and then let it stand for 1 hour to make it oxidize more thoroughly;

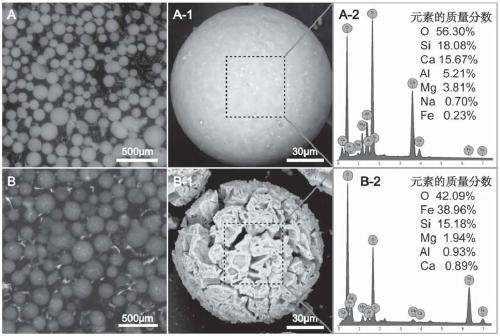

[0036] (2) Loading metal ions by in-situ precipitation method: 6g spherical geopolymer particles (particle size 75-300μm, specific surface area 68.26m 2 / g) dispersed in the tetravalent cerium salt aqueous solution of step (1), placed on a heating magnetic stirrer for loading for 1 hour (stirring speed 300rpm, heating temperature 30 degrees Celsius);

[0037] (3) Aging: the spherical geopolymer particles loaded with cerium ions in step (2) were stopped from stirring, and left to age for 2 hours;

[0038] (4) Washing: the product obtained in step (3) is washed several times with distilled water to remove chloride ions, excessive cerium ions and alkali introduced therein, and detect whether the washing is cl...

Embodiment 2

[0045] (1) Preparation of ferric salt solution: 30gFeCl3 ·6H 2 O was dissolved in 200g distilled water;

[0046] (2) Loading metal ions by in-situ precipitation method: 2g spherical geopolymer particles (particle size 150-800μm, specific surface area 46.58m 2 / g) dispersed in the ferric salt aqueous solution of step (1), placed on a heating magnetic stirrer for 0.5 hours to load (stirring speed 500rpm, heating temperature 45 degrees Celsius);

[0047] (3) Aging: Stop stirring the spherical geopolymer particles loaded with iron ions in step (2), and leave to age for 1 hour;

[0048] (4) washing: the product obtained in step (3) is washed several times with distilled water to remove chloride ions, excessive iron ions and alkali introduced therein, and detect whether the washing is clean (using silver ion method, ICP, atomic absorption spectrometry respectively Photometric method and pH meter are detected), and the pH of washing solution is controlled at 7-9 after washing;

[...

Embodiment 3

[0055] (1) Preparation of aluminum salt solution: 25gAlCl 3 ·6H 2 O was dissolved in 200g distilled water;

[0056] (2) Loading metal ions by in-situ precipitation method: 1.8g spherical geopolymer particles (particle size 150-300μm, specific surface area 10.37m 2 / g) dispersed in the aluminum salt aqueous solution of step (1), placed on a heating magnetic stirrer for 0.3 hours to load (stirring speed 600rpm, heating temperature 75 degrees Celsius);

[0057] (3) Aging: Stop stirring the spherical geopolymer particles loaded with aluminum ions in step (2), and then leave it to age for 0.5 hour;

[0058] (4) Washing: the product obtained in step (3) is washed several times with distilled water to remove chloride ions, excessive aluminum ions and alkali introduced therein, and detect whether the washing is clean (using silver ion method, ICP, atomic absorption spectrometry respectively Photometric method and pH meter detect), after washing, control the pH of the washing soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com