Okra extract and application thereof in preparation of cosmetics

A technology for extracts and cosmetics, which is applied to okra extract and its application in the preparation of cosmetics, can solve problems such as damage, skin irritation, and excessive amounts of harmful components, and achieves the improvement of skin elasticity, skin color improvement, and good activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

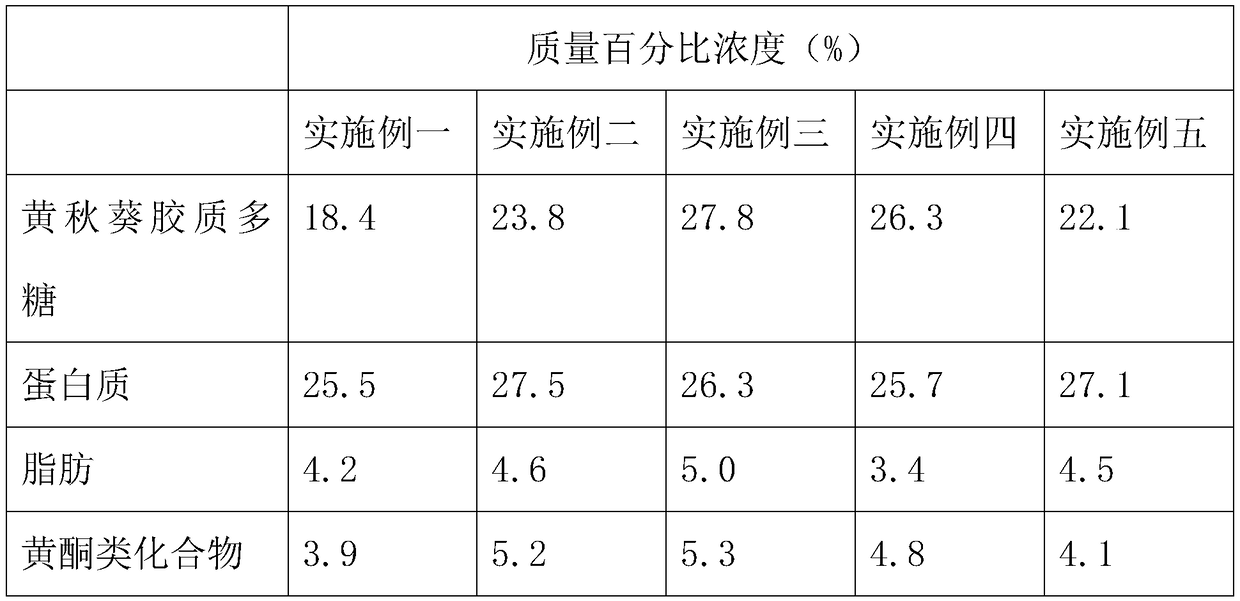

Embodiment 1

[0025] A kind of okra extract proposed by the present invention comprises okra pectin polysaccharide, protein, fat and flavonoids;

[0026] The preparation method of described okra pectin polysaccharide comprises the following steps:

[0027] S1: Weigh 8g of okra dry powder, then select a food acid buffer with a pH value of 6 as the extract, then weigh 6g of activated cellulase, and then add the okra dry powder, extract and cellulase to the reaction tank in sequence and set the time of enzymolysis to 120min, the temperature of enzymolysis to 45°C, and the ratio of solid to liquid to 1:48.5 for constant temperature enzymolysis to obtain the extract of okra colloidal polysaccharide, which is heat-treated and heated The temperature is set to 98°C, and the heating time is set to 3 minutes;

[0028] S2: Then pour the extract in S1 into a centrifuge, set the centrifugal speed of the centrifuge to 4500 rpm, extract the supernatant by centrifugation, then move the supernatant to a ro...

Embodiment 2

[0036] A kind of okra extract proposed by the present invention comprises okra pectin polysaccharide, protein, fat and flavonoids;

[0037] The preparation method of described okra pectin polysaccharide comprises the following steps:

[0038] S1: Weigh 10g of okra dry powder, then select a food acid buffer with a pH value of 6 as the extract, then weigh 10g of activated cellulase, and then add the okra dry powder, extract and cellulase to the reaction tank in sequence and set the time of enzymolysis to 120min, the temperature of enzymolysis to 45°C, and the ratio of solid to liquid to 1:48.5 for constant temperature enzymolysis to obtain the extract of okra colloidal polysaccharide, which is heat-treated and heated The temperature is set to 98°C, and the heating time is set to 3 minutes;

[0039] S2: Then pour the extract in S1 into a centrifuge, set the centrifugal speed of the centrifuge to 4500 rpm, extract the supernatant by centrifugation, then move the supernatant to a ...

Embodiment 3

[0047] A kind of okra extract proposed by the present invention comprises okra pectin polysaccharide, protein, fat and flavonoids;

[0048] The preparation method of described okra pectin polysaccharide comprises the following steps:

[0049] S1: Weigh 12g of okra dry powder, then select a food acid buffer with a pH value of 6 as the extract, then weigh 10g of activated cellulase, and then add the okra dry powder, extract and cellulase to the reaction tank in sequence and set the time of enzymolysis to 130min, the temperature of enzymolysis to 50°C, and the ratio of solid to liquid to 1:49 to carry out constant temperature enzymolysis to obtain the extract of okra colloidal polysaccharide, which is heat-treated and heated The temperature is set to 100°C, and the heating time is set to 6 minutes;

[0050] S2: Then pour the extract in S1 into a centrifuge, set the centrifugal speed of the centrifuge to 5000 rpm, extract the supernatant by centrifugation, then move the supernata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com