An automatic honey shaker

A honey machine and electric motor technology, applied in the field of automatic honey shaker, can solve the problems of easily crushed honeycomb, cumbersome operation, low efficiency, etc., and achieve the effects of improving cutting quality, avoiding pollution, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

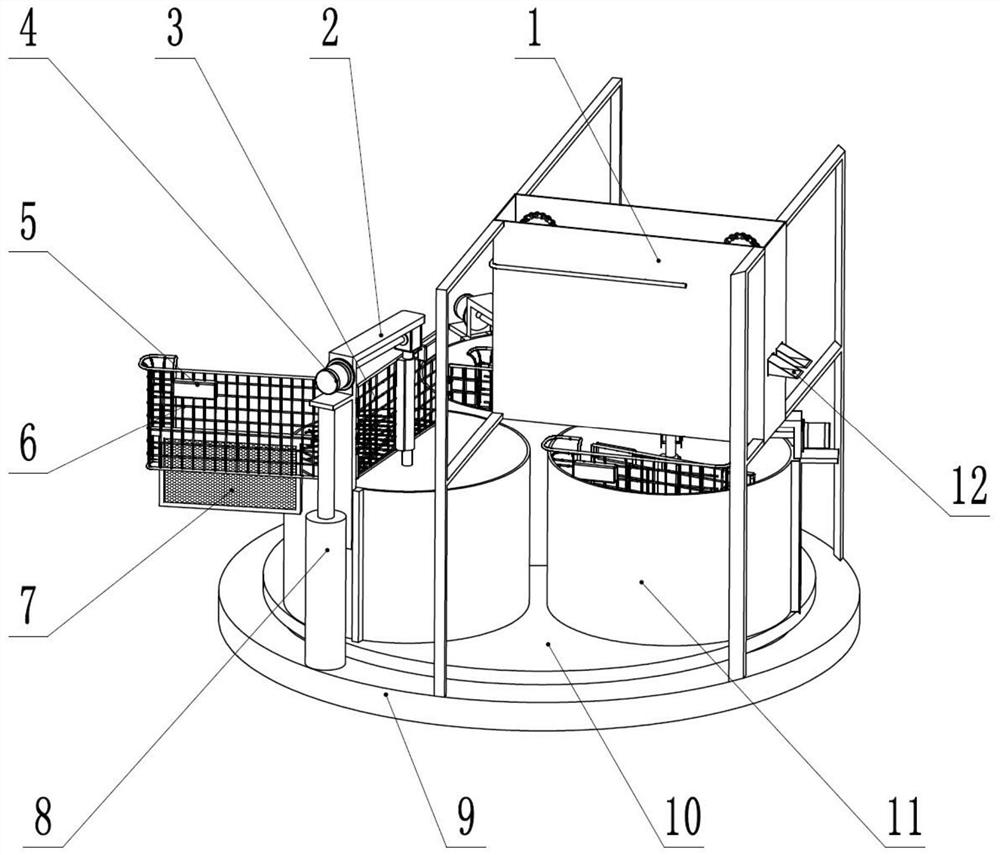

[0021] In embodiment 1, such as Figure 1-7 As shown, the present invention includes a base 9, a wax cap cutting mechanism and a honey shaking mechanism.

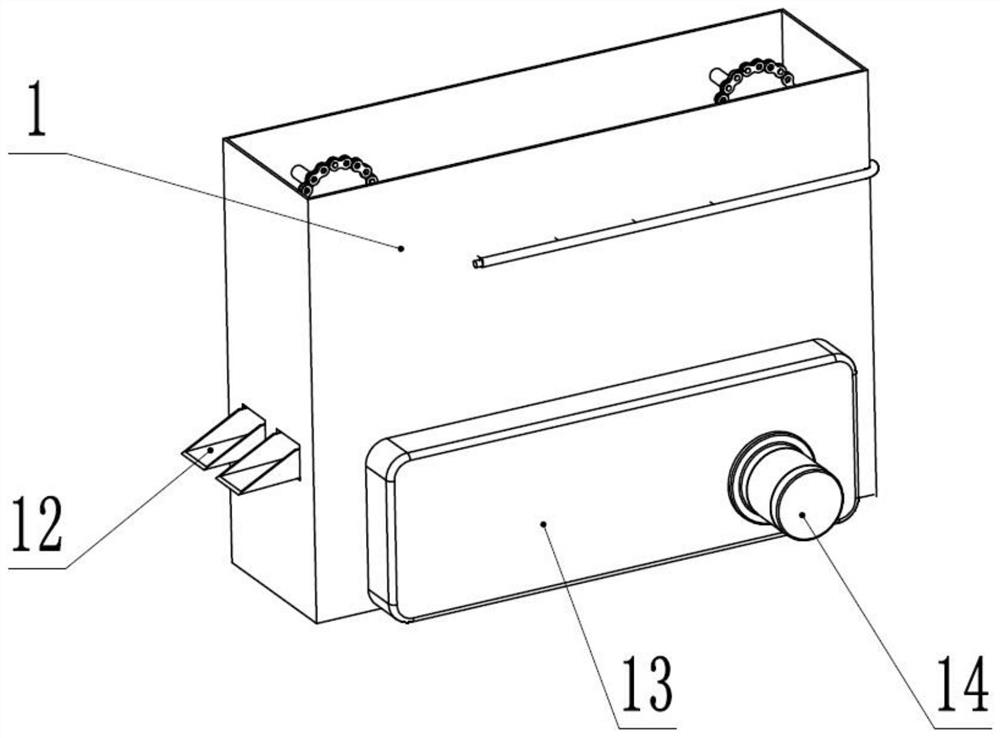

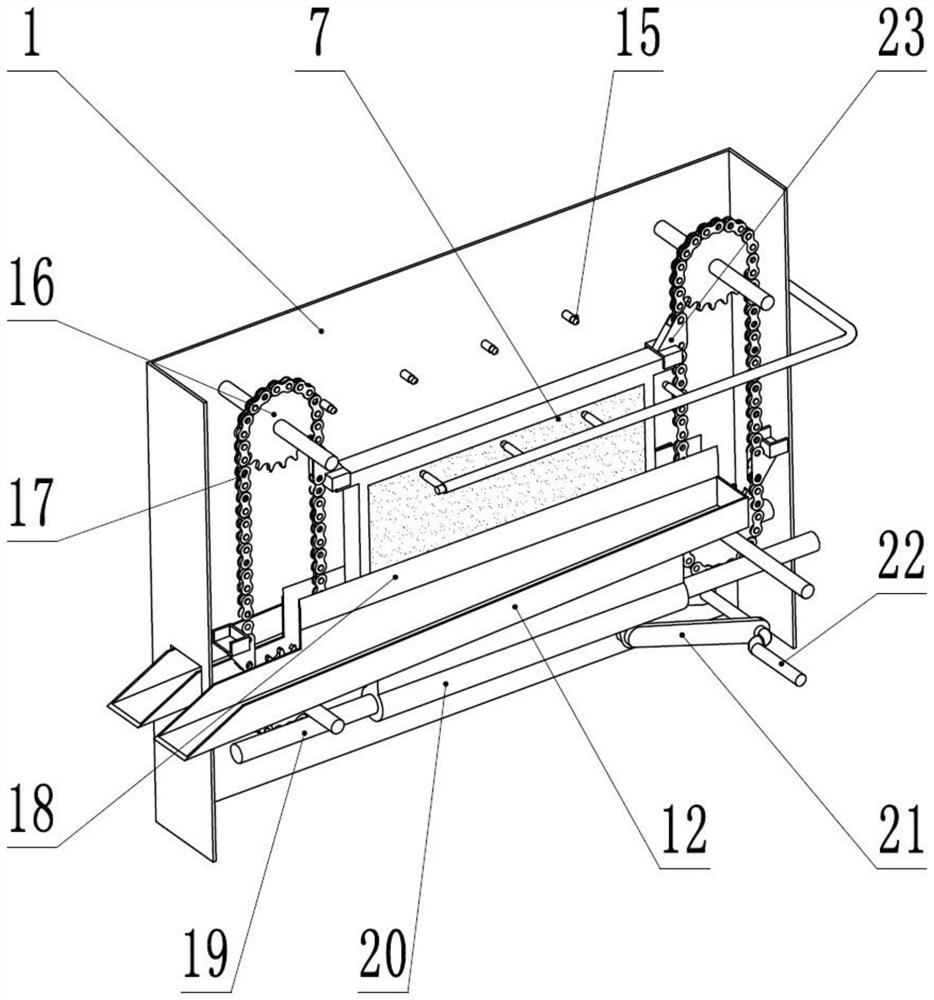

[0022] Such as figure 2 , 3 As shown, the wax cap cutting mechanism includes a housing 1, a No. 1 motor 14, a sprocket 16, a chain 17 structure, a gear box 13, a cutter 18, and a water pump.

[0023] The housing 1 is fixed on the base 9, the upper and lower ends of the housing 1 are respectively provided with openings, and a group of nozzles 15 are respectively arranged on both sides near the upper opening, and the nozzles 15 are driven by a water pump to spray water to the honeycomb 7 wax cap.

[0024] There are two parallel cutters 18 below the nozzle 15 in the housing 1. When the honeycomb 7 is put into the machine, the two cutters 18 are respectively located on both sides of the honeycomb 7, and the honeycomb 7 is cut off by the cutter 18. wax cover. Each of the outer surfaces of the cutters 18 is fixedly provided ...

Embodiment 2

[0035] In Embodiment 2, the main structure of this embodiment is the same as that of Embodiment 1. In this embodiment, the same technical features as those of Embodiment 1 will not be repeated, and only the technical features different from Embodiment 1 will be described.

[0036] Such as Figure 6 As shown, the outer surface of the side wall of the honey bucket 11 is provided with a vertical chute 29 compatible with the vertical bar of the support 2, and the vertical bar is located in the chute 29 and can move vertically along the chute 29 . A horizontal plate 24 is fixed on the vertical bar of the support 2, and a vertical cylinder 8 is arranged on the base 9 below the horizontal plate 24 of the support 2 on the No. 3 station. When the cylinder 8 is inflated, it stretches upward Standing on the horizontal plate 24, the horizontal plate 24 drives the support 2, the grid plate and the honeycomb 7 to move upward.

[0037] When in use, when the honey bucket rotates to the No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com