Biomass charcoal/iron oxide composite material and preparation method thereof

A technology of biomass carbon and composite materials, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve problems such as poor cycle performance, low conductivity of iron oxide, large volume expansion, etc., and achieve low cost and convenient access , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

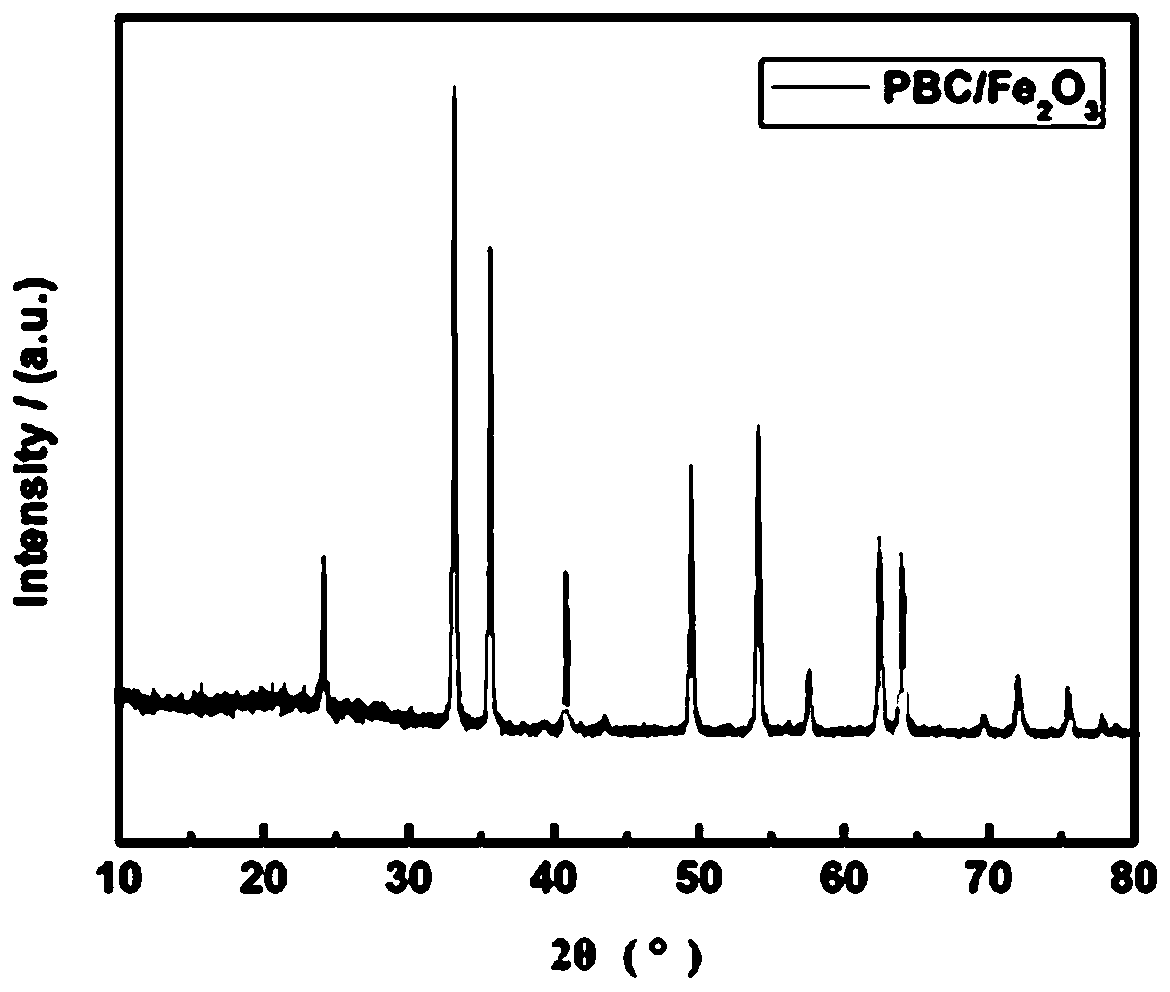

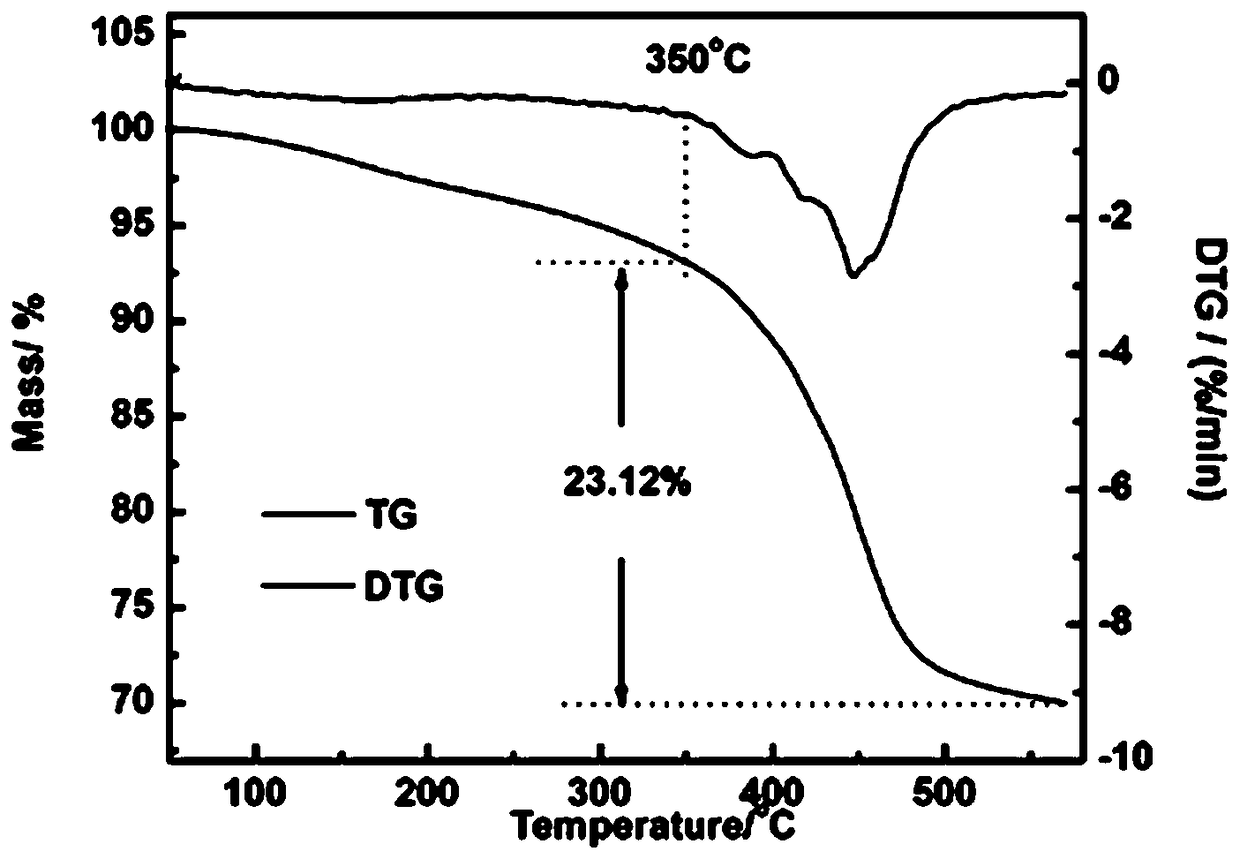

[0030] Clean the collected sycamore leaves with deionized water, then soak 24h with the potassium hydroxide solution of 1mol / L, in the air blast oven for 80 o C evaporated to dryness. Then collect it in a porcelain ark and put it in a tube furnace, the argon gas is 99% pure, the flow rate of argon gas is 30-60ml / min, and the temperature is raised to 900 at a heating rate of 5°C / min. o C, calcined at this temperature for 2h. Then wash with dehydrochloric acid solution and deionized water until the pH of the filtrate is neutral, and put it in a dry box at 80 o C and dried for 10 h, ground and sieved to obtain sycamore leaf biomass carbon. Add 0.4g sycamore leaf biomass carbon material to the NaH with a volume of 400ml and a concentration of 0.054g / L 2 PO 4 aqueous solution, and then add 7.2ml of FeCl with a concentration of 1.5mol / L 3 The solution was transferred to a flask oil bath and stirred and heated for 2 hours. After cooling to room temperature, it was transferred to...

Embodiment 2

[0032] Clean the collected bamboo leaves with deionized water, then soak them in 0.5mol / L potassium hydroxide solution for 48 hours, and dry them in a blast oven for 85 hours. o C evaporated to dryness. Then collect it in a porcelain ark and put it in a tube furnace, the argon gas is 99% pure, the argon gas flow rate is 30-60ml / min, and the temperature is raised to 950 at a heating rate of 5°C / min. o C, calcined at this temperature for 2h. Then wash with dehydrochloric acid solution and deionized water until the pH of the filtrate is neutral, and place it in a dry box at 85 o C for 10 h, ground and sieved to obtain bamboo leaf biomass carbon. Add 0.1g of biomass carbon material to NaH with a concentration of 0.03g / L 2 PO 4 aqueous solution, and then add 10.8ml of FeCl with a concentration of 1mol / L 3 The solution was transferred to a flask oil bath and stirred and heated for 4 hours. After cooling to room temperature, it was transferred to a beaker and placed in a microwa...

Embodiment 3

[0034] The hair and pine bark that the mass ratio of 1:1 that collects is cleaned with deionized water is good, soaks 20h with the potassium hydroxide solution of 1.5mol / L then, in blast drying box 75 oC evaporated to dryness. Then collect it in a porcelain ark and put it in a tube furnace. The argon gas is 99% pure, and the argon gas flow rate is 30-60ml / min. o C, calcined at this temperature for 4h, then. Then wash with dehydrochloric acid solution and deionized water until the pH of the filtrate is neutral, and put it in a dry box at 75 o Dry 20h under C, grind and sieve to obtain hair and pine bark biomass carbon. Add 1.5g of hair and pine bark biomass carbon material to NaH with a concentration of 0.07g / L 2 PO 4 aqueous solution, and then add 3.6ml of FeCl with a concentration of 3mol / L 3 The solution was transferred to a flask oil bath and stirred and heated for 1 hour. After cooling to room temperature, it was transferred to a beaker and placed in a microwave oven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com