Environmentally-friendly red glue cleaning compound

A technology of cleaning agent and red glue, which is applied in the directions of detergent compounding agent, detergent composition, detergent composition solvent, etc. Fast and effective, scrubbing and rinsing clean, good cleaning results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

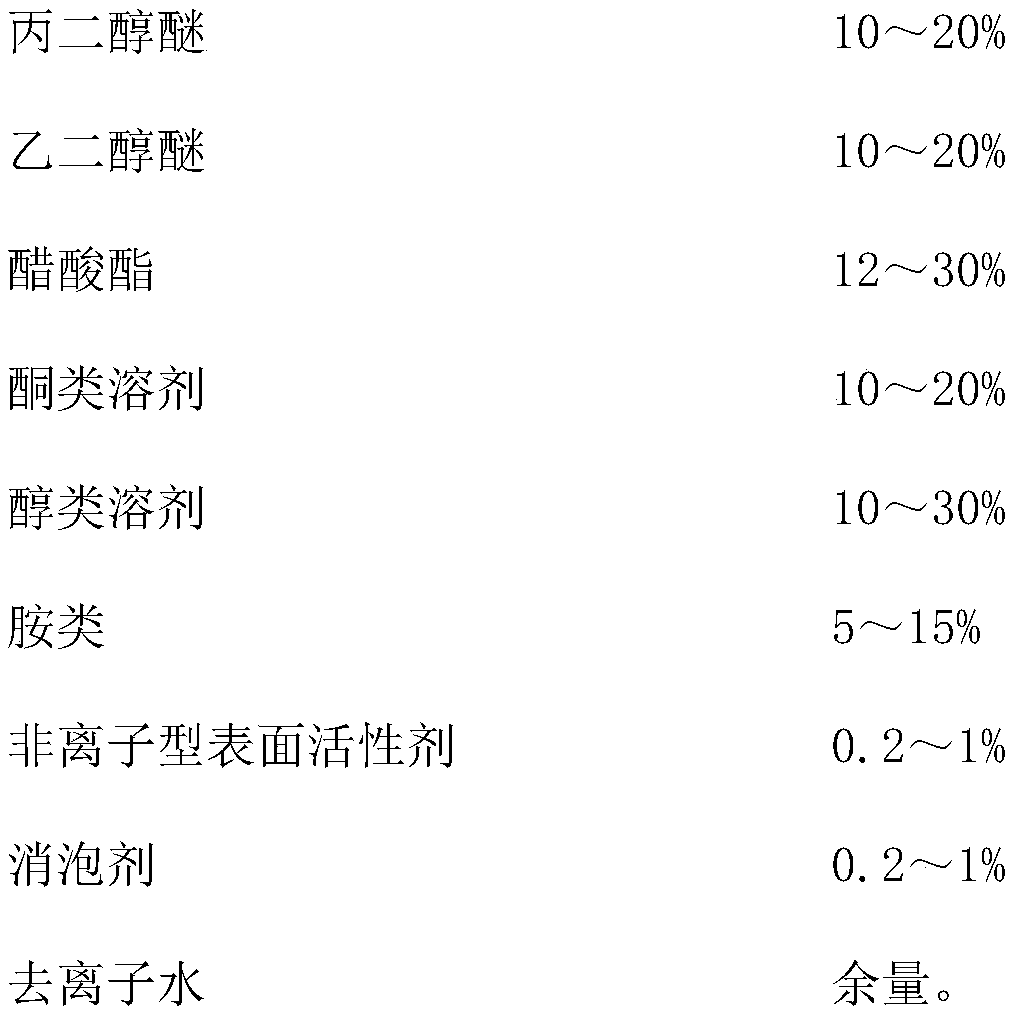

Method used

Image

Examples

Embodiment 1

[0022] The mass percentage (%) of each component is: propylene glycol butyl ether 15, ethylene glycol butyl ester 15, propylene glycol methyl ether acetate 15, diacetone alcohol 10, isopropanol 20, diethanolamine 5, non-ionic surfactant 0.5, defoamer 0.5, deionized water 19.

[0023] Preparation steps:

[0024] a. Accurately weigh each component in turn according to the formula;

[0025] b. Sequentially add propylene glycol butyl ether, ethylene glycol butyl ester, propylene glycol methyl ether acetate, diacetone alcohol, and isopropanol to the reactor and stir and mix, and continue to stir for 5 minutes until the mixing is complete;

[0026] c. Sequentially add diethanolamine, nonionic surfactant, and deionized water to the reaction kettle, and continue to stir for 5 minutes until the mixture is uniform;

[0027] d. Add the defoamer to the reaction kettle to eliminate the bubbles, and the environmentally friendly red glue cleaner is prepared.

Embodiment 2

[0029] The mass percentage (%) of each component is: propylene glycol butyl ether 20, ethylene glycol butyl ester 20, propylene glycol methyl ether acetate 15, diacetone alcohol 10, isopropanol 10, diethanolamine 5, non-ionic surfactant 0.5, defoamer 0.5, deionized water 19.

[0030] The preparation steps are the same as in Example 1.

Embodiment 3

[0032] The mass percentage (%) of each component is: propylene glycol methyl ether 15, ethylene glycol butyl ester 15, propylene glycol methyl ether acetate 15, diacetone alcohol 10, isopropanol 20, diethanolamine 5, non-ionic surfactant 0.5, defoamer 0.5, deionized water 19.

[0033] Preparation steps:

[0034] a. Accurately weigh each component in turn according to the formula;

[0035] b. Sequentially add propylene glycol methyl ether, ethylene glycol butyl ester, propylene glycol methyl ether acetate, diacetone alcohol, and isopropanol to the reactor and stir and mix, and continue to stir for 5 minutes until the mixing is complete;

[0036] c. Sequentially add diethanolamine, nonionic surfactant, and deionized water to the reaction kettle, and continue to stir for 5 minutes until the mixture is uniform;

[0037] d. Add the defoamer to the reaction kettle to eliminate the bubbles, and the environmentally friendly red glue cleaner is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com