Outer floating roof storage tank with lightning rods and metal roof

A technology of lightning rod and external floating roof, which is applied in the direction of transportation and packaging, electrical components, containers, etc. It can solve the problems of storage tank explosion, large area of floating roof, and ineffective protection by protection methods, so as to avoid lightning induction hazards and the effect of reducing fire accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

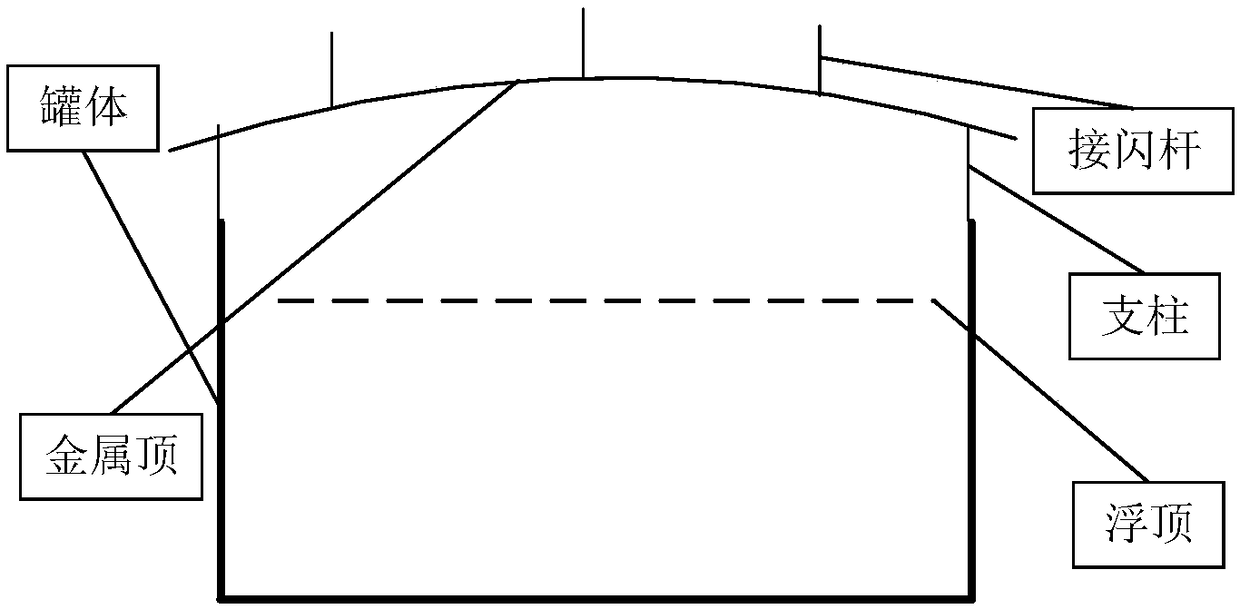

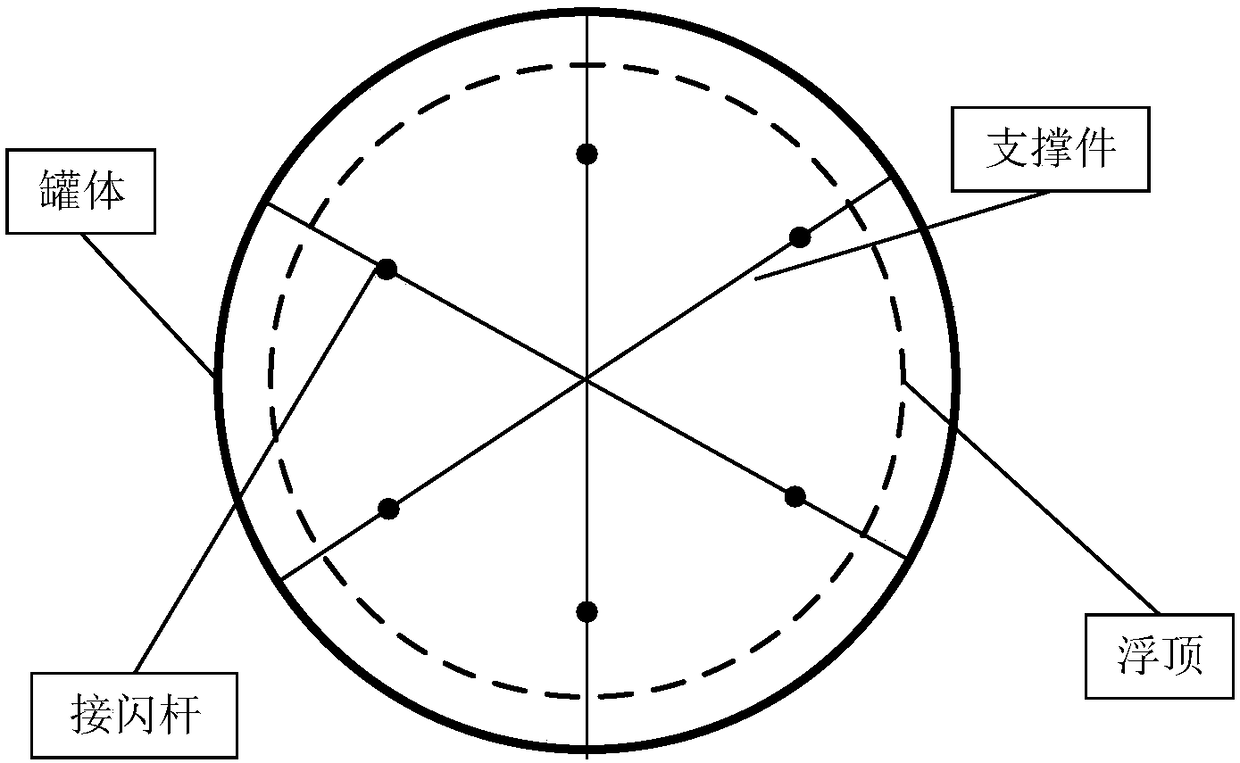

[0019] combine figure 1 , figure 2 As shown, an external floating roof storage tank with a lightning rod and a metal roof includes a tank body, a floating roof, a metal roof, and a lightning rod. A metal roof is erected outside the floating roof, and multi-branched flash rod.

[0020] The metal plate is made of aluminum or other metal materials, and the pillars are welded to the angle steel on the top of the tank, and are electrically connected to the tank body reliably, which has a certain shielding effect.

[0021] The lightning rod support rod is fixed on the fixed support on the metal plate, and is electrically connected with the metal plate reliably.

[0022] The lightning rod is made of hot-dip galvanized round steel or steel pipe, with a cross-sectional area of not less than 176mm 2 .

[0023] The length of the lightning rod is 2m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Pole length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com