Piezoelectric device, liquid discharging head, and liquid discharging apparatus

A technology of piezoelectric devices and piezoelectric elements, applied in the direction of piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc., can solve the problem that the vibration plate displacement cannot be fully improved question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

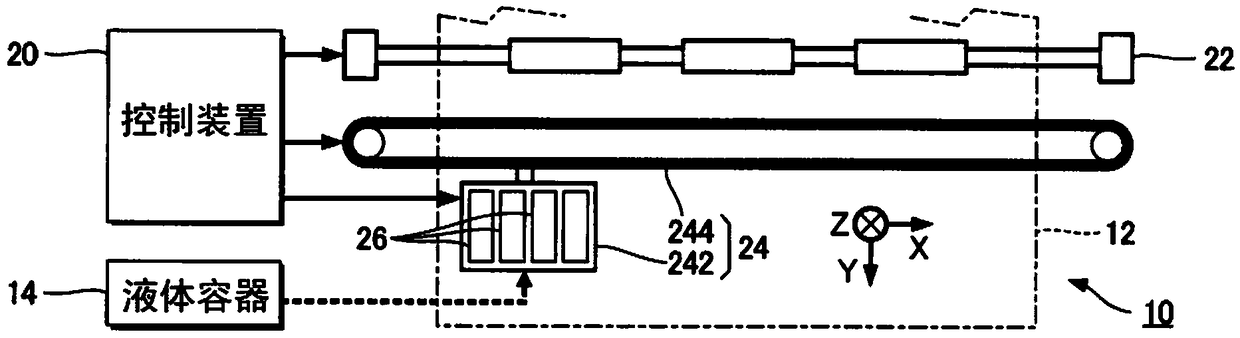

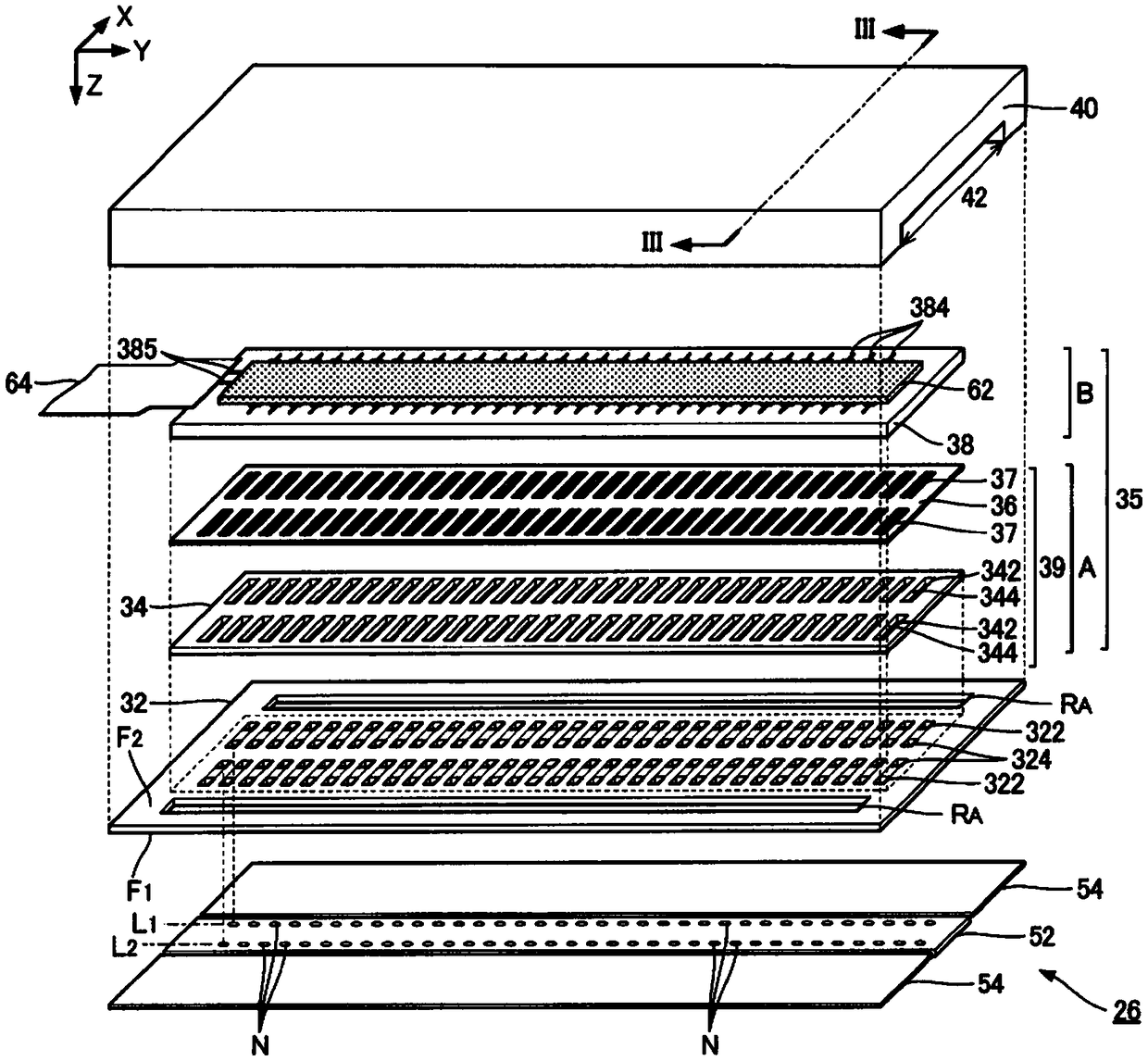

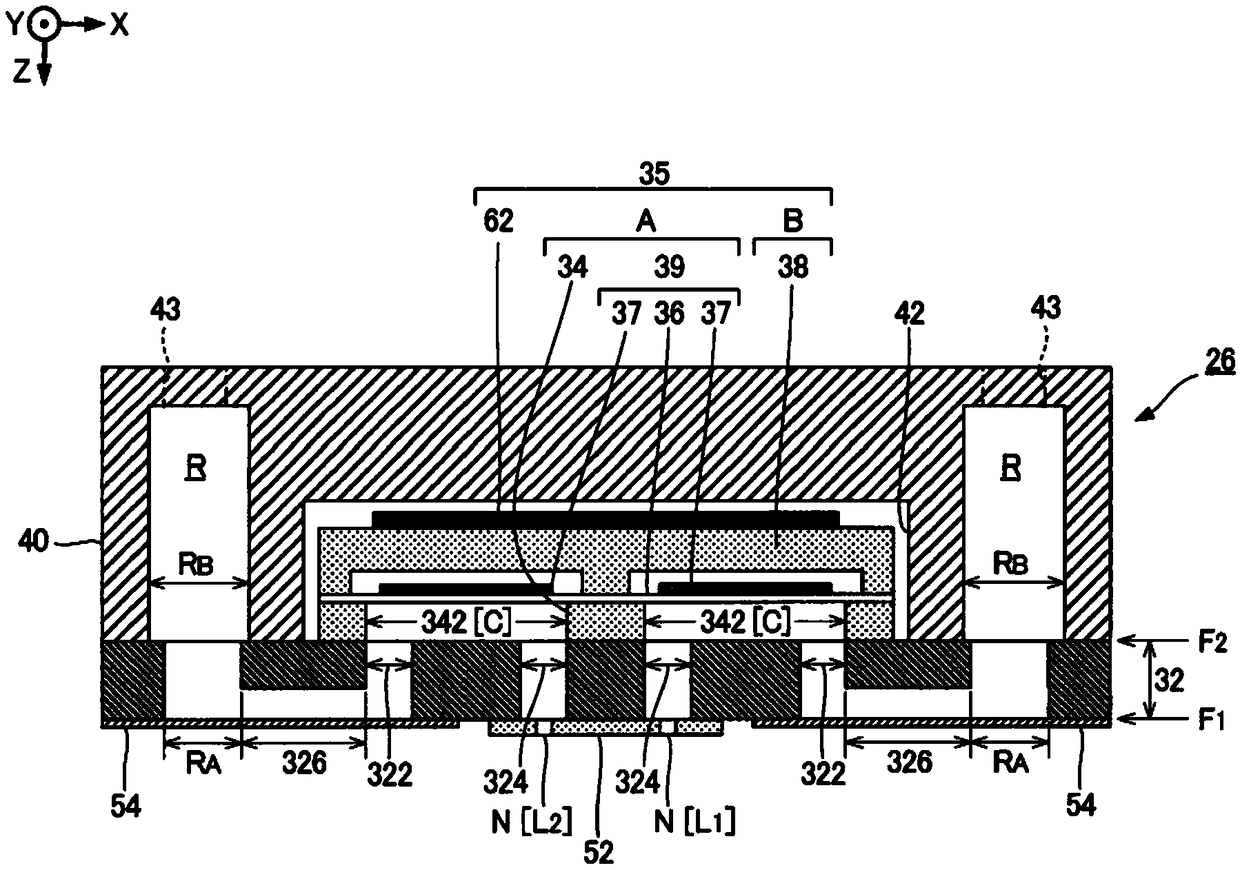

[0044] figure 1 It is a configuration diagram illustrating an example of the liquid ejection device 10 according to the first embodiment of the present invention. The liquid discharge device 10 of the first embodiment is an inkjet printing device that discharges ink as an example of a liquid onto a medium 12 . The medium 12 is typically printed paper, but any printing object such as a resin film or cloth may be used as the medium 12 . like figure 1 As shown, a liquid container 14 for storing ink is fixed in the liquid ejection device 10 . As the liquid container 14 , for example, an ink cartridge detachable from the liquid ejection device 10 , a pouch-shaped ink pack formed of a flexible film, or an ink tank capable of replenishing ink is used. A plurality of inks of different colors are stored in the liquid container 14 .

[0045] like figure 1 As shown, the liquid ejection device 10 includes a control device 20 , a transport mechanism 22 , a movement mechanism 24 , and ...

no. 2 approach

[0098] A second embodiment of the present invention will be described. For the elements whose operation and function are the same as those of the first embodiment in each of the embodiments exemplified below, the symbols used in the description of the first embodiment are used, and detailed descriptions thereof are appropriately omitted. Although the case of the shape of the pressure chamber C (the shape of the vibration region P) having the same length in the direction of the axis Gx as the length in the direction of the axis Gy was exemplified in the first embodiment, in the second embodiment, the The case where the shape of the pressure chamber C (shape of the vibration region P) differs in length in the direction of the axis Gx from that in the direction of the axis Gy will be exemplified.

[0099] Figure 11 It is an enlarged cross-sectional view and a plan view of the piezoelectric device 39 of the second embodiment. Figure 11 Section view of ( Figure 11 The figure ...

no. 3 approach

[0117] A third embodiment of the present invention will be described. In the third embodiment, a specific configuration example of the piezoelectric element 37 related to the piezoelectric device 39 of the first embodiment will be described. Figure 17 as well as Figure 18 Yes Figure 4 A specific structural example of the piezoelectric element 37 is shown in FIG. Figure 17 It is a plan view when viewing the piezoelectric device 39 of the third embodiment from the Z direction. Figure 18 Yes Figure 17 Sectional view XVIII-XVIII of piezoelectric device 39 is shown.

[0118] like Figure 17 as well as Figure 18 As shown, the piezoelectric element 37 of the third embodiment is arranged on the vibrating plate 36 so as not to overlap the center O of the pressure chamber C but to overlap the inner circumference 345 of the pressure chamber C in a plan view. , has an inner edge 37A on the center O side of the pressure chamber C and an outer edge 37B on the side wall 344 sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com