Gold ore grinding classification system and grinding classification processing technology

A grading system and grading processing technology, which is applied in grain processing, solid separation, wet separation, etc., can solve the problems of low equipment processing capacity, low equipment utilization rate, ore muddying, etc., achieve simple structure layout, and improve processing capacity , Reduce the effect of sand return ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

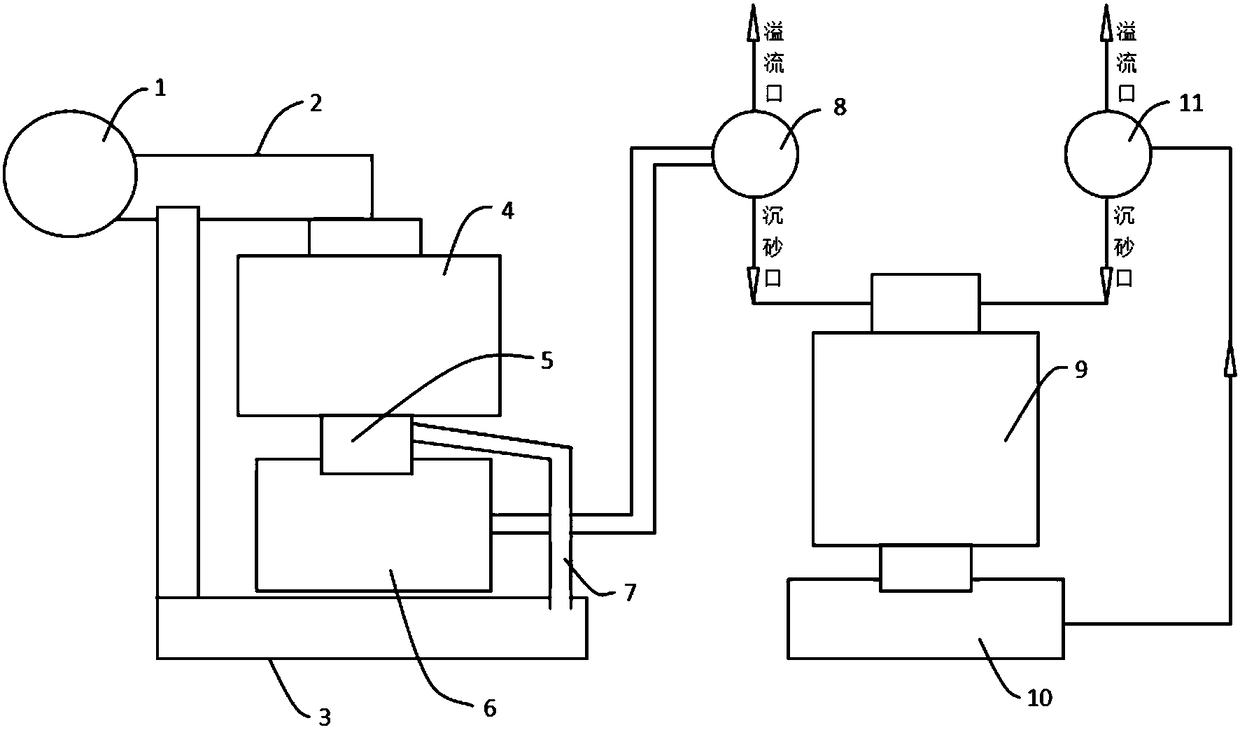

[0031] like figure 1 As shown, a kind of gold ore grinding and grading system in this embodiment includes a two-stage grinding and grading system, and the one-stage grinding and grading system includes a semi-autogenous mill 4, a cylindrical sieve 5, 1 # Classification pump pool 6 and inspection classification cyclone group 8, the second stage grinding and classification system includes ball mill 9, 2 # Classification pump pool 10 and control classification cyclone group 11.

[0032] The raw ore in the fine ore bin 1 is transported to the semi-autogenous mill 4 through the raw ore belt conveyor 2, and the cylindrical screen 5 is set at the ore discharge port of the semi-autogenous mill 4. 1 # The grading pump pool 6 is arranged under the cylindrical screen 5, and the ore discharge port of the cylindrical screen 5 is connected with a chute 7, and the other end of the chute 7 is connected to the return belt conveyor 3, and the return belt conveyor 3 is connected to the raw ore ...

Embodiment 2

[0043] The system structure of this embodiment is basically the same as that of Embodiment 1, the difference is:

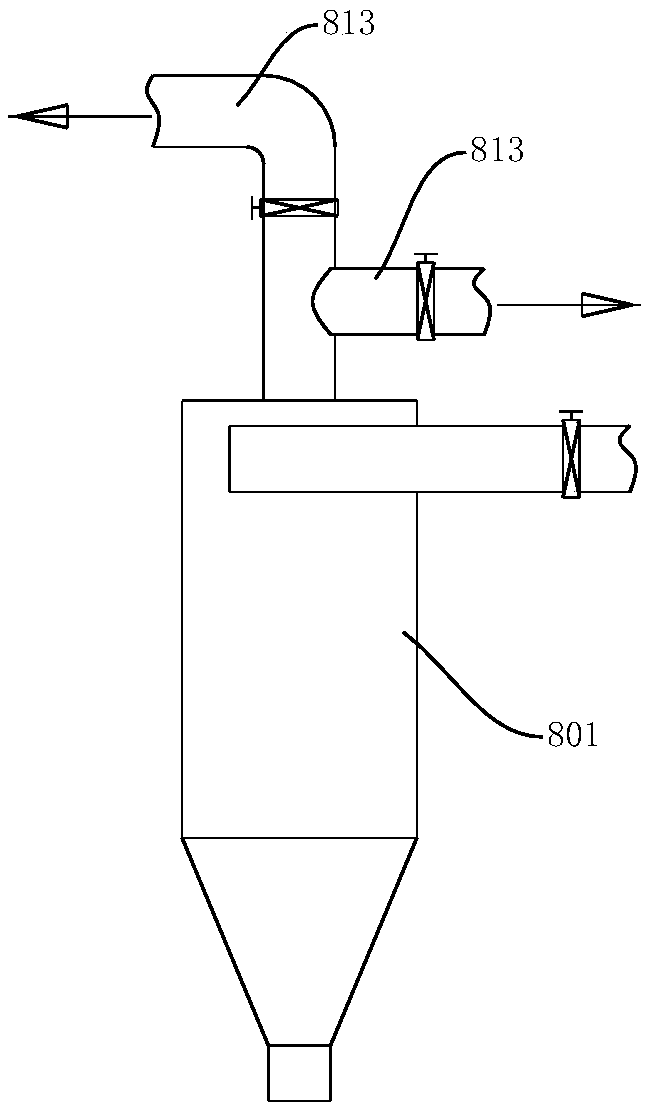

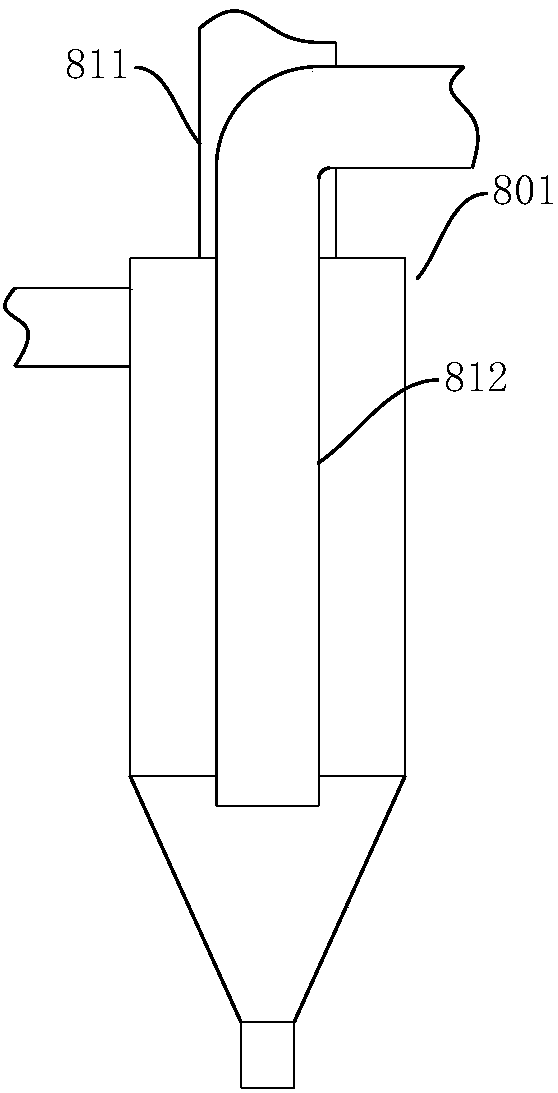

[0044] like image 3 As shown, in this embodiment, the inspection and classification cyclone group 8 includes a plurality of cyclones 801, and the cyclone 801 is provided with two overflow pipes, respectively overflow pipe one 811 and overflow pipe two 812, Overflow pipe 2 812 is set in overflow pipe 1 811 and extends into the cyclone through the inlet of overflow pipe 1, and the discharge port of overflow pipe 1 811 is connected to the flotation stirring tank, overflow pipe 2 812 The discharge port is connected to the 2nd stage of the two-stage grinding and classification system # The grading pump pool and the grit outlet of the cyclone 801 are connected to the ball mill. Two overflow pipes are set in the cyclone of the cyclone group, in which the fine material after separation is directly discharged into the flotation operation through the outlet of overflow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com