Phosphogypsum modified biochar method and application

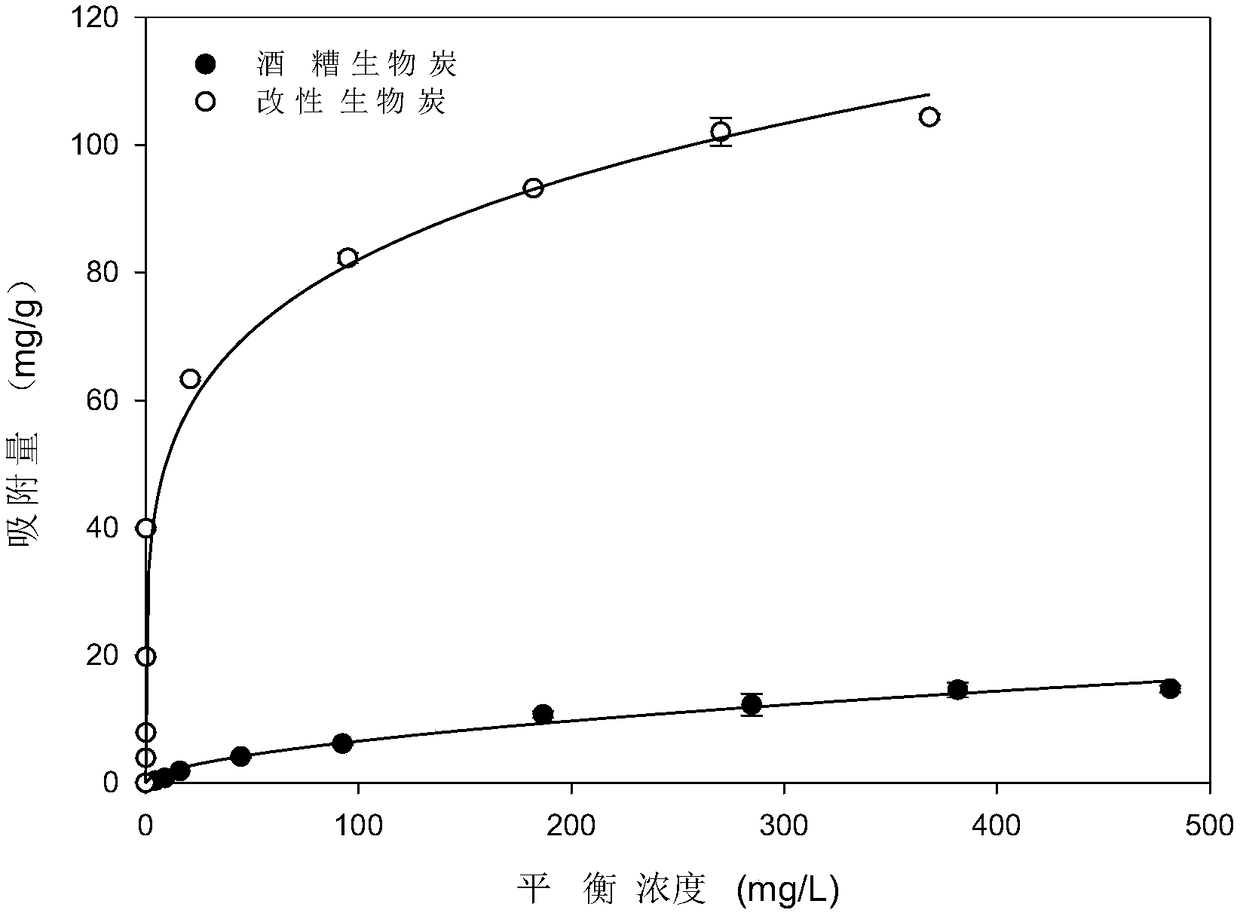

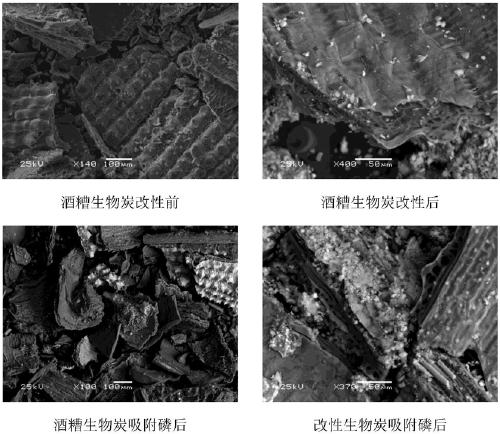

A technology of phosphogypsum and biochar, applied in chemical instruments and methods, alkali metal compounds, and other chemical processes, can solve the problems of cumbersome reaction process, high cost, and complicated modification technology, and achieve wide source of raw materials, adsorption The effect of improved performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of phosphogypsum modified biochar includes the following steps:

[0026] (1) Dry the distiller’s grains at 105°C to remove water, then grind and sieve for later use;

[0027] (2) The phosphogypsum recovered from the phosphogypsum storage yard is dried at 105°C for use;

[0028] (3) Take the phosphogypsum and distiller's grains in a weight ratio of 1:10 and mix them evenly, add water according to the W:V solid-liquid ratio of 2:3 to fully mix the two, and dry them at 105°C to obtain modified distiller's grains (namely modified Biomass) spare;

[0029] (4) Pyrolyzing modified distiller's grains under anaerobic or anoxic conditions to produce biochar, which is called phosphogypsum modified biochar.

[0030] (5) Grinding and sieving the prepared modified biochar, wherein the aperture of the sieve is 149-850 μm.

Embodiment 2

[0032] A preparation method of phosphogypsum modified biochar includes the following steps:

[0033] (1) Dry the dregs of traditional Chinese medicine at 100°C to remove water, then grind and sieve for later use;

[0034] (2) The phosphogypsum recovered from the phosphogypsum yard is dried at 100°C for use;

[0035] (3) Take the phosphogypsum and the traditional Chinese medicine slag in a weight ratio of 3:10 and mix them evenly, add water to the W:V solid-to-liquid ratio of 2:3 to fully mix the two, and dry them at 100°C to obtain the modified traditional Chinese medicine slag (ie Modified biomass) spare;

[0036] (4) Pyrolyzing modified traditional Chinese medicine residue under anaerobic or anoxic conditions to produce biochar, which is called phosphogypsum modified biochar.

[0037] (5) Grinding and sieving the prepared biochar, wherein the aperture of the sieve is 149-850 μm.

Embodiment 3

[0039] A preparation method of phosphogypsum modified biochar includes the following steps:

[0040] (1) Dry the straw at 120°C to remove the moisture, then grind and sieve for later use;

[0041] (2) The phosphogypsum recovered from the phosphogypsum storage yard is dried at 120°C for use;

[0042] (3) Take the phosphogypsum and straw according to the weight ratio of 1:2 and mix them evenly. According to the ratio of W:V to solid-liquid ratio of 2:3, add water and stir thoroughly to make the two fully mixed. Dry at 120°C to obtain modified straw (namely modified Biomass) spare;

[0043] (4) Pyrolyzing modified straw under anaerobic or anoxic conditions to produce biochar, which is called phosphogypsum modified biochar.

[0044] (5) Grinding and sieving the prepared biochar, wherein the aperture of the sieve is 149-850 μm.

[0045] In Examples 1 to 3 of the present invention, the modified biomass is pyrolyzed in a muffle furnace by nitrogen purging, where the nitrogen purging rate is 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com