Dust recovery treatment device in process of aluminum profile processing

A technology for aluminum profile processing and dust recovery, which is applied in the direction of combined devices, gas treatment, and dust removal, and can solve problems such as large dust, environmental pollution, and debris splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

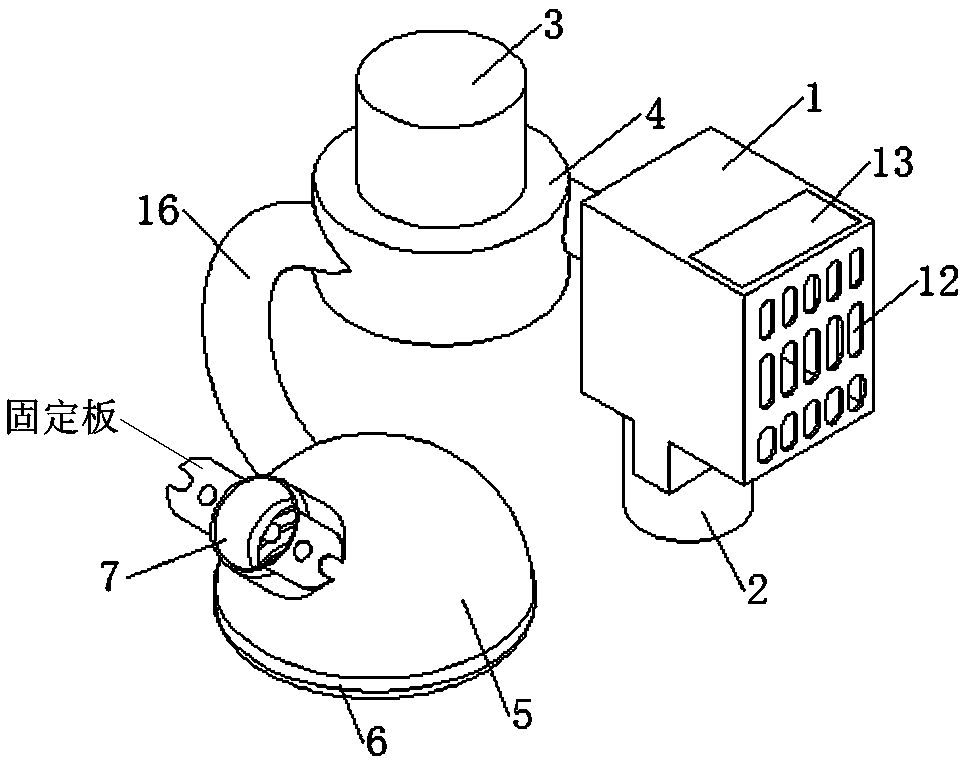

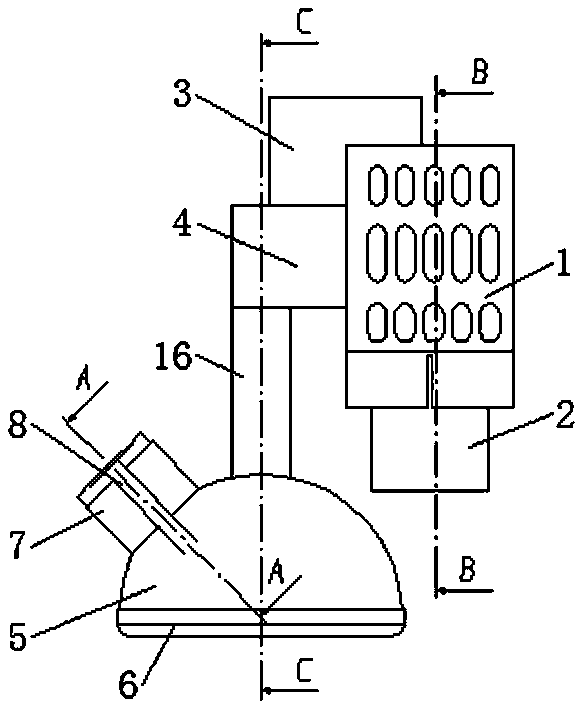

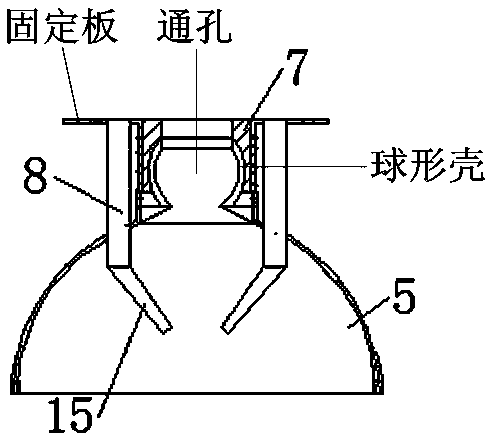

[0024] see Figure 1-4 The dust recycling and processing device shown in the aluminum profile processing process includes a dust collection cover 5 , a turbine device and a filter box 1 .

[0025] An air inlet and an air outlet 12 are arranged on opposite side walls of the filter box 1, the bottom of the filter box 1 is connected to a storage tank 2, and the storage tank 2 communicates with the lower end of the filter box. The filter box 1 includes a filter screen 9 in the middle, an adsorption layer is set between the filter screen 9 and the air outlet 12, which can be an activated carbon bag 10, and a movable cover plate is set on the top of the adsorption layer to facilitate the replacement of the activated carbon bag 10. There is a cavity between the filter screen 9 and the air inlet, and the bottom of the cavity communicates with the storage tank 2 . The filter box 1 is fixedly installed with the non-movable end of the external processing machine tool through a bracket (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com