A kind of mixed filter material and filter device with the mixed filter material

A filter device and filter material technology, applied in the directions of loose filter material filter, filtration separation, gravity filter, etc., can solve the problems of poor working effect of the lower filter material, the same, wear particle size of quartz sand, etc., so as to improve the filtering effect. effect, increase filter effect, effect of good filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A mixed filter material in this embodiment is prepared by mixing two or more filter material particles. Different types of filter material particles have different specific gravity, and the particle size of each filter material particle is evenly distributed. The particle size distribution of the filter material particles is uniform. Through the calculation of the Stokes formula, the particle size of different filter material particles is controlled, so that the sedimentation velocity ratio of different filter material particles in water is within the preset range, and the preset range is 0.95 -1.05, when the sedimentation velocity ratio of different filter material particles in water is 1, it is the best state, that is, the sedimentation velocity of different filter material particles in water is the same.

[0030] In this embodiment, uniform particle size distribution means that the particle size distribution curve of the same filter material particles is smooth, there...

Embodiment 2

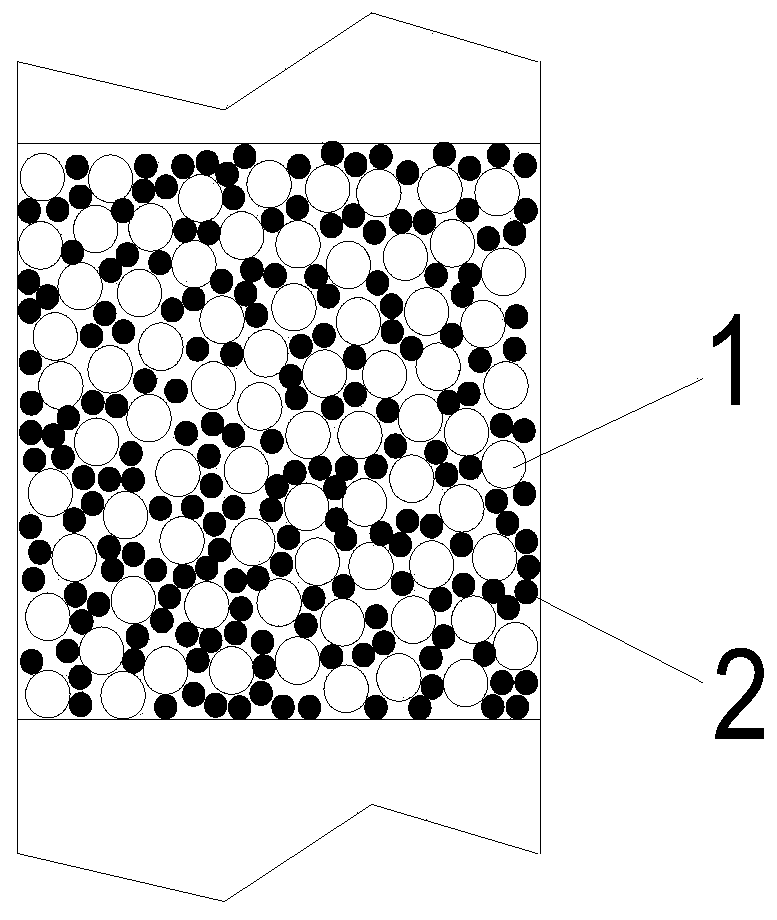

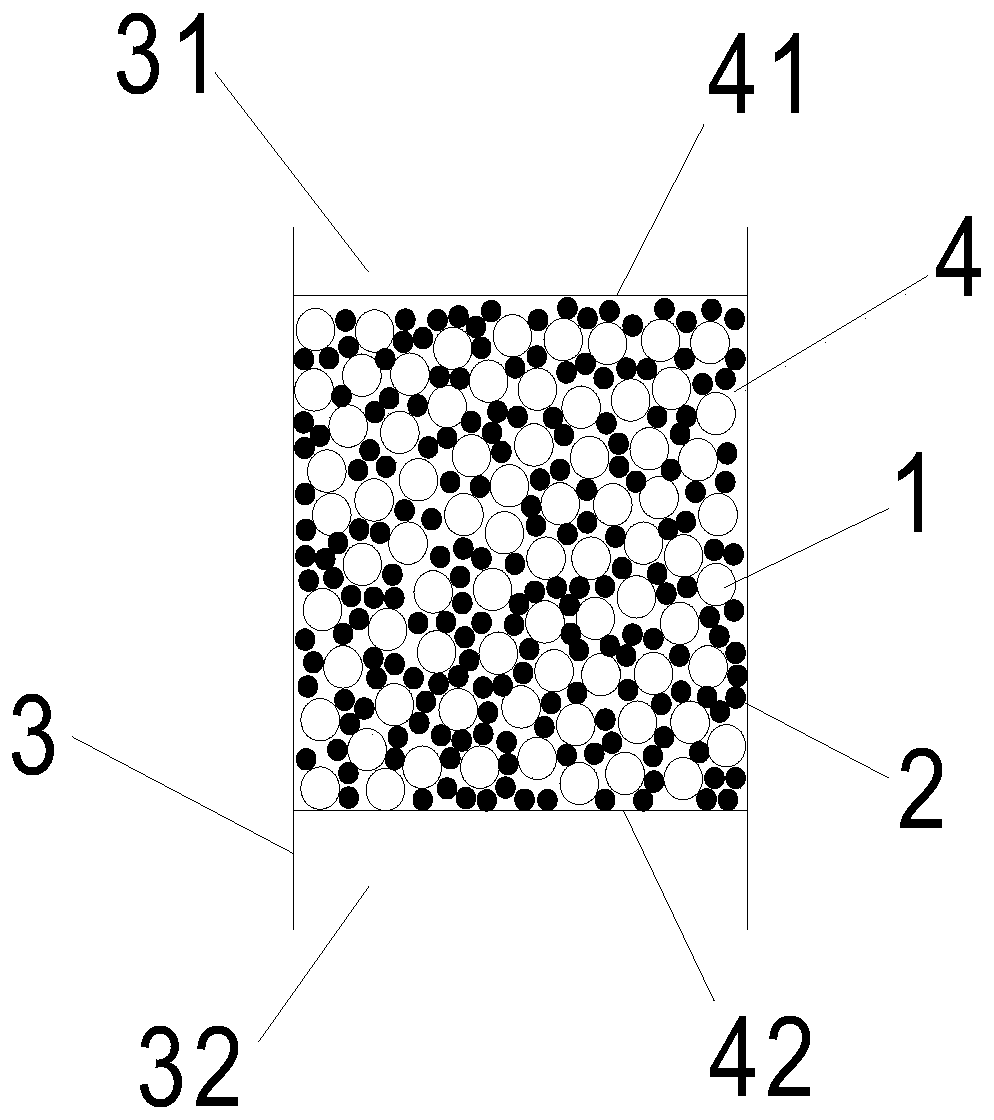

[0037] In this embodiment, on the basis of the above-mentioned embodiments, a mixed filter material is proposed. The mixed filter material includes quartz sand 1 and garnet 2, the quartz sand 1 and garnet 2 are evenly mixed, and the quartz sand 1 and garnet 2 are both spherical. Or a spherical structure, in which the mass ratio of quartz sand 1 to garnet 2 is 2, the average particle size of quartz sand 1 is 100 μm, the average particle size of garnet 2 is 80 μm, and the minimum particle size of quartz sand 1 in the mixed filter material is The ratio of the particle size to the maximum particle size is 0.6, the ratio of the minimum particle size to the maximum particle size of garnet 2 in the mixed filter material is 0.6, and the sedimentation velocity of quartz sand 1 and garnet 2 in water is the same or similar; Example The two filter materials are fully mixed to form a mixed filter material, which directly replaces the single-layer quartz sand filter material in the tradition...

Embodiment 3

[0041] The difference between this embodiment and the above embodiment is that in this embodiment, the mass ratio of quartz sand 1 to garnet 2 is 0.5, the average particle size of quartz sand 1 is 100 μm, and the average particle size of garnet is 80 μm , the ratio of the minimum particle size to the maximum particle size of quartz sand 1 in the mixed filter material is 0.8, and the ratio of the minimum particle size to the maximum particle size of garnet 2 in the mixed filter material is 0.8, and the small particle size in the present embodiment The proportion of garnet 2 increases, more garnet 2 is mixed between the particles of quartz sand 1, and the gap between filter materials is small, which is beneficial to the filtration of water containing fine impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com