Cascade connection robust fault-tolerance forecast control method for permanent magnet synchronous motor

A permanent magnet synchronous motor, predictive control technology, applied in the direction of motor control, motor generator control, electronic commutation motor control, etc., can solve problems affecting reliability, permanent magnet demagnetization, predictive control motor system parameter changes, etc., to achieve The effect of improving the effect, eliminating parameter perturbation, improving control accuracy and reliability of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

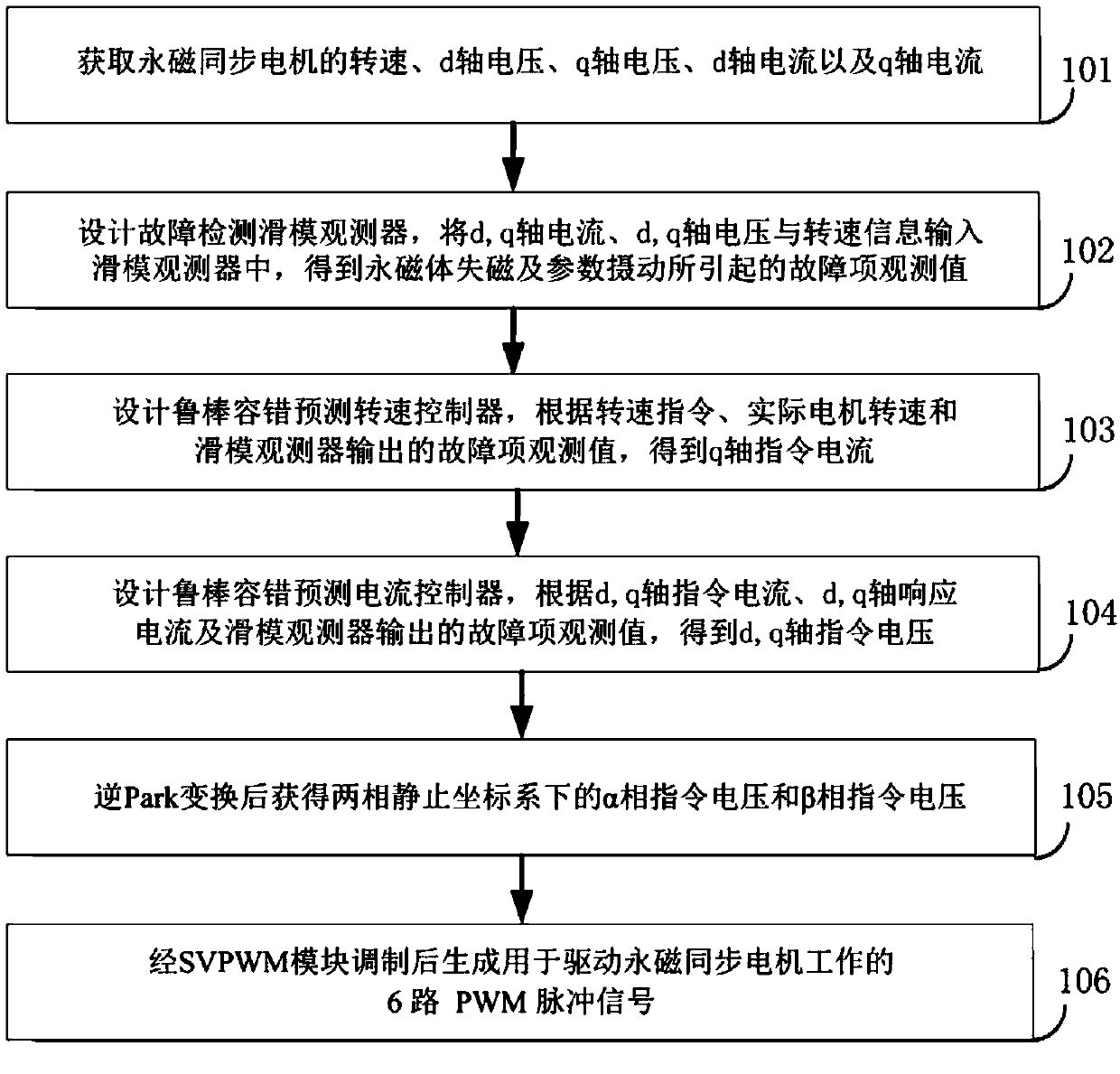

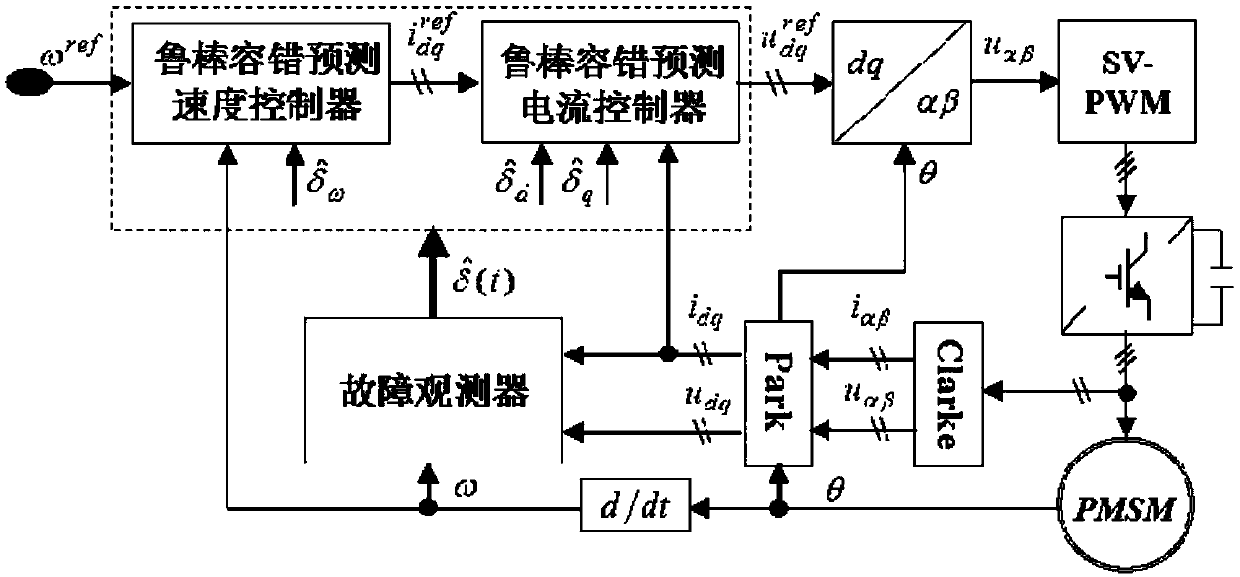

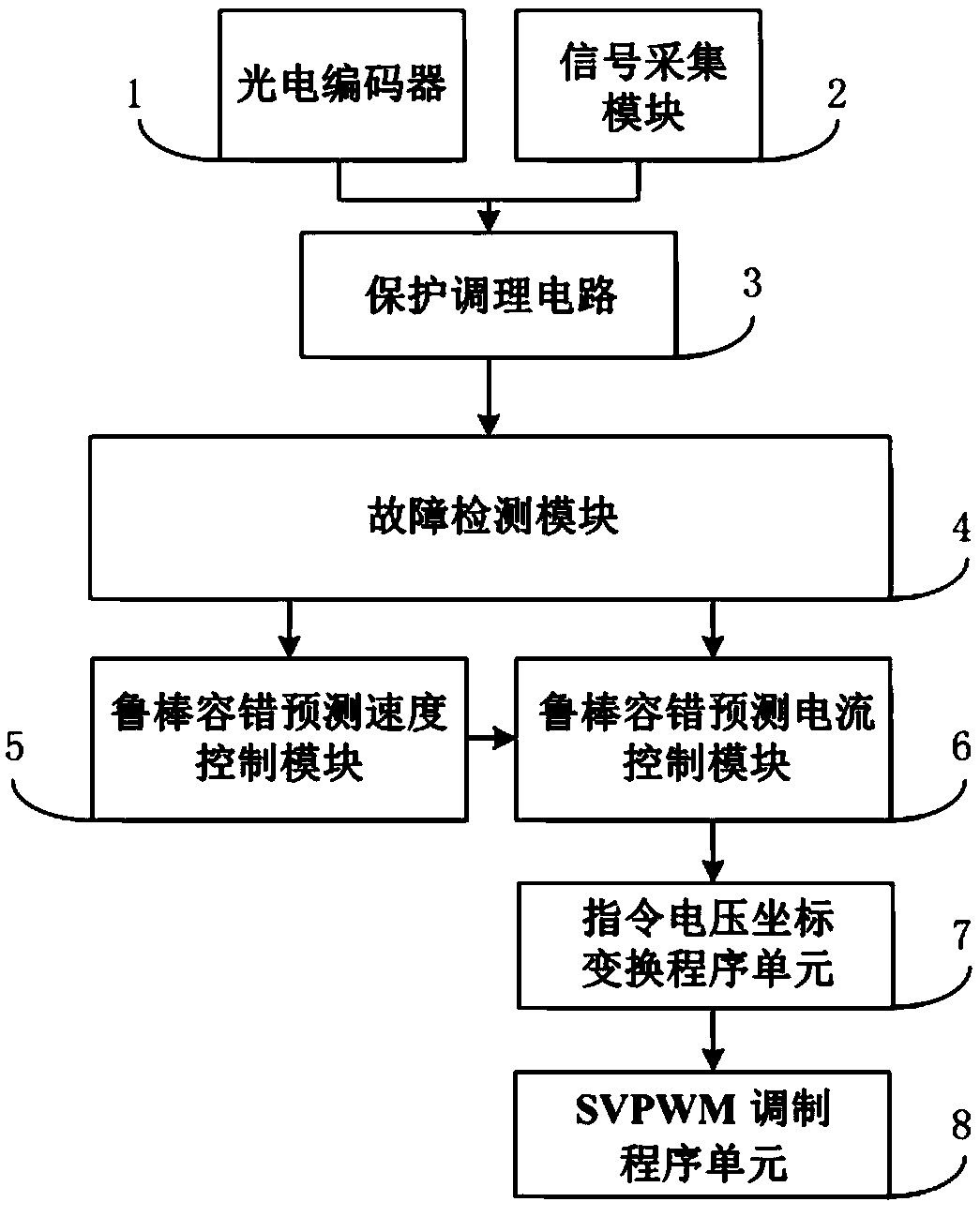

[0056] like figure 1 and figure 2 As shown, the implementation steps of a cascaded robust fault-tolerant predictive control method for permanent magnet synchronous motors in this embodiment include:

[0057] Step 1) Obtain the rotational speed ω and the d-axis voltage u of the permanent magnet synchronous motor d , q-axis voltage u q , d-axis current i d and the q-axis current i q ;

[0058] Step 2) Design the integral terminal sliding mode observer for fault detection, and take the rotational speed ω and the d-axis voltage u d , q-axis voltage u q , d-axis current i d and the q-axis current i q Input the fault detection integral terminal sliding mode observer to obtain the observed value of the fault term

[0059] The detailed steps of step 2) include:

[0060] 2.1) Establish the permanent magnet synchronous motor state equation under the parameter perturbation shown in formula (1) and the permanent magnet demagnetization fault situation;

[0061]

[0062] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com