Robot matched flexible bearing structure

A technology of flexible bearings and robots, which is applied in the direction of bearing components, shafts and bearings, rolling contact bearings, etc., can solve the problems of increasing rated load, fewer varieties and specifications, and small batches, so as to increase rated load, increase ball filling angle, The effect of increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

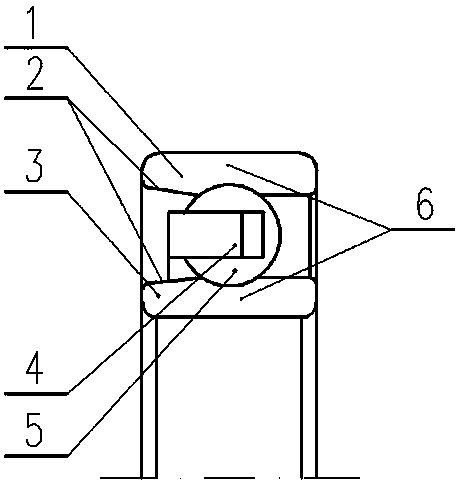

[0014] combine Figure 1-2 , This embodiment includes an outer ring 1, an inner ring 3, a cage 4, and steel balls 5. The outer ring 1 and the inner ring 3 are coaxially placed, and a cage 4 is provided between the outer ring 1 and the inner ring 3. Steel balls 5 are embedded in the cage 4. The size of the steel balls is 1 / 2 to 3 / 3 of the width of the bearing section. 4. Compared with ordinary bearings, the number of steel balls is greatly increased, and the filling angle is between 260º and 330º. The outer ring 1 and the inner ring 3 are subjected to cold treatment.

[0015] A ball filling gap 2 is provided between the outer ring 1 and the inner ring 3, and the wall thickness of the ring 6 of the outer ring 1 and the inner ring 3 is 4-6mm, which is about 2.5% of the outer diameter.

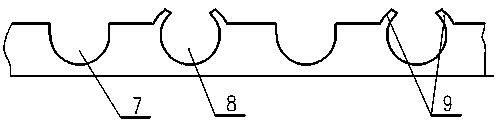

[0016] The cage 4 pockets in this embodiment have two types: the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com