Four-port port plate for torque balance and shock mitigation

A valve plate and window technology, applied in the field of hydraulic pumps, can solve the problems of increasing the size of the axial piston pump, complex structure of the pump body, poor oil suction and discharge, etc., and achieve the effect of improving variable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

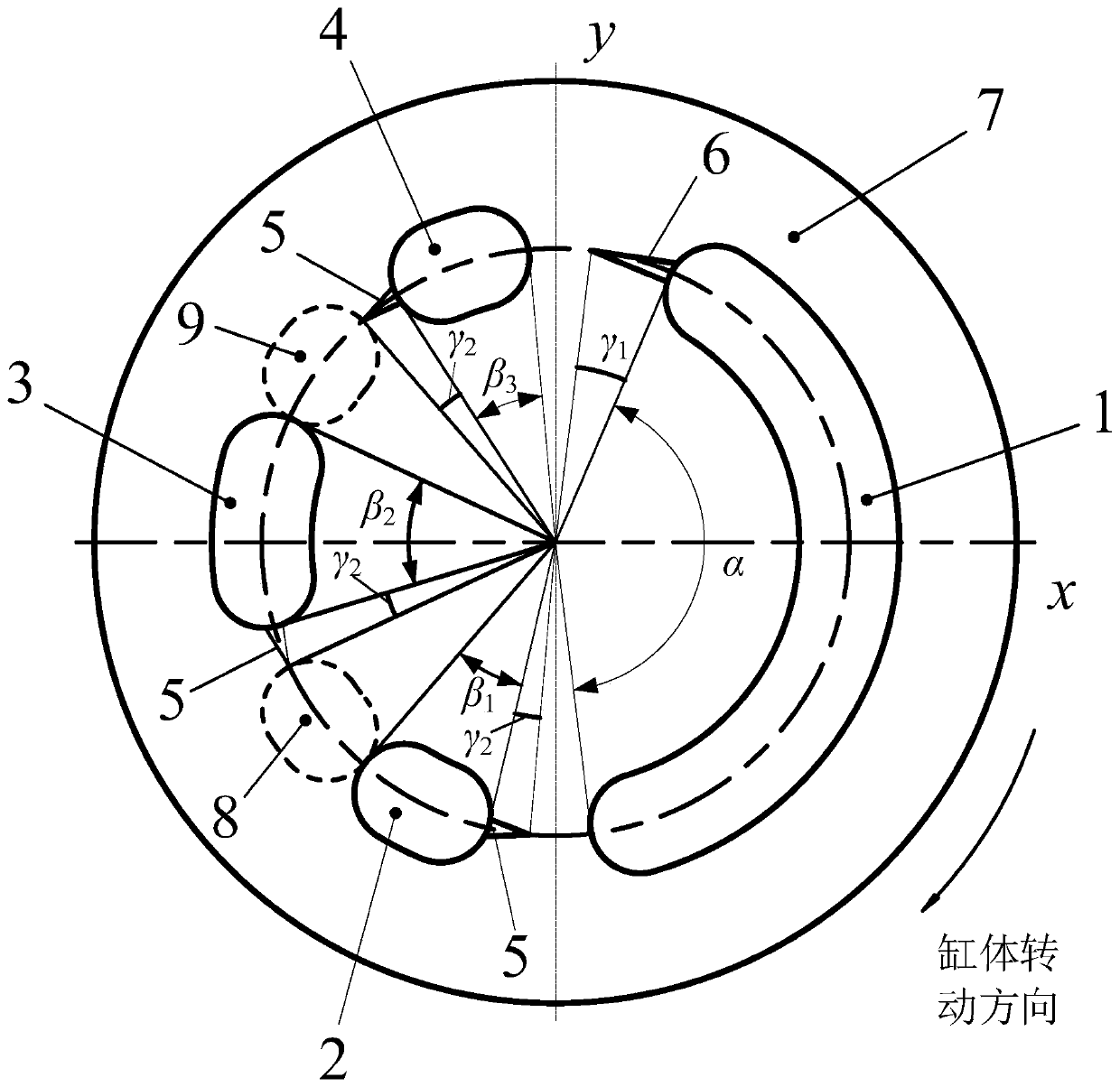

[0032] Such as Figure 6 As shown, the four-distribution window distribution plate that can balance the torque and relieve the impact is a disc 7, and an oil suction window 1 and 3 oil discharge windows are set on the disc, among which, the 3 oil discharge windows include: row Ⅰ The oil window 2, the second oil discharge window 3 and the third oil discharge window 4; the oil suction window, the first oil discharge window, the second oil discharge window and the third oil discharge window are all waist-shaped through holes with circular arcs at both ends , and are sequentially distributed on the same circle with the disc center as the center, the index circle diameter and width of the oil suction window and oil discharge window are the same as the index circle diameter and width of the waist-shaped hole at the lower end of the plunger hole in the cylinder body, The spread angles of the oil suction window, the first oil discharge window, the second oil discharge window and the t...

Embodiment 2

[0038] Such as Figure 7 As shown, the four-distribution window distribution plate that can balance the torque and relieve the impact is a disc 7, and an oil suction window 1 and 3 oil discharge windows are set on the disc, among which, the 3 oil discharge windows include: row Ⅰ The oil window 2, the second oil discharge window 3 and the third oil discharge window 4; the oil suction window, the first oil discharge window, the second oil discharge window and the third oil discharge window are all waist-shaped through holes with circular arcs at both ends , and are sequentially distributed on the same circle with the disc center as the center, the index circle diameter and width of the oil suction window and oil discharge window are the same as the index circle diameter and width of the waist-shaped hole at the lower end of the plunger hole in the cylinder body, The spread angles of the oil suction window, the first oil discharge window, the second oil discharge window and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com