Direct heat absorption type energy storage power generation system based on vacuum heat absorbing tubes

A technology of a power generation system and a heat-absorbing tube is applied in the field of direct heat-absorbing energy storage power generation system, which can solve the problems of difficult cleaning and maintenance, deposition of dust and debris on the mirror surface, affecting the reflection and absorption of sunlight, etc., so as to reduce the difficulty of tracking adjustment. and cost, reducing tracking accuracy requirements, increasing power generation and revenue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

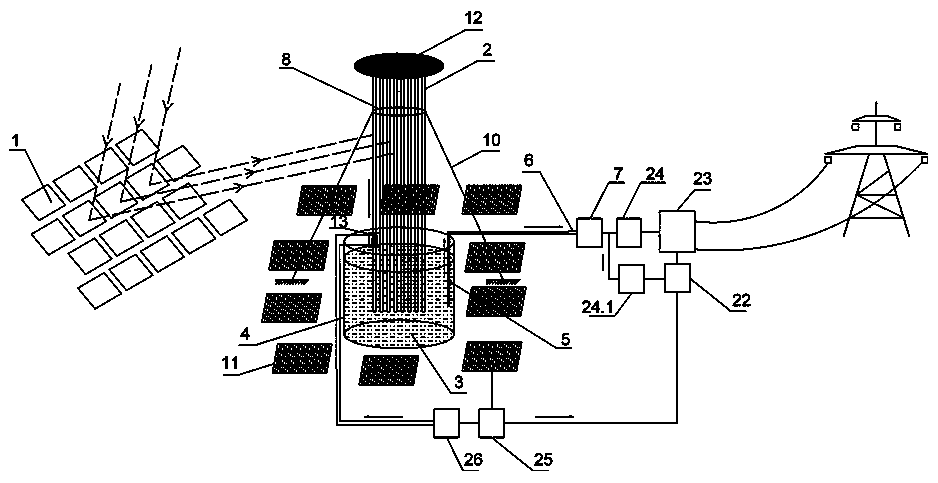

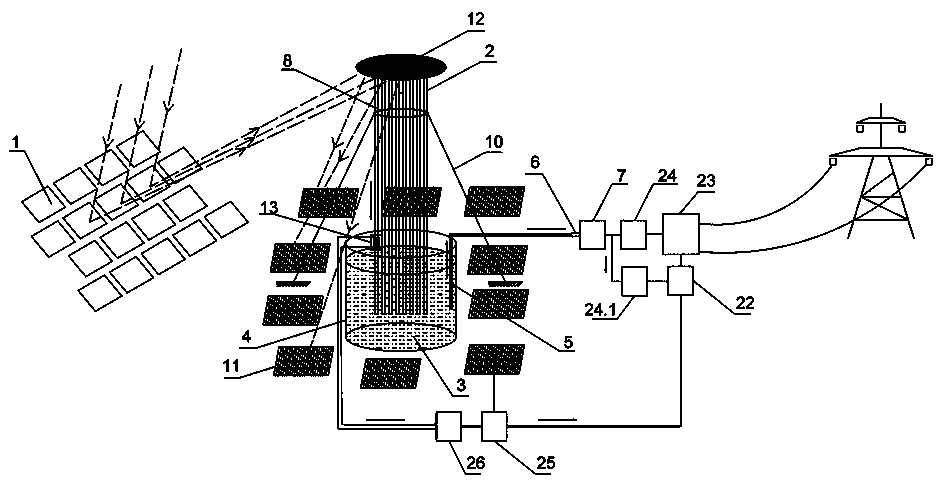

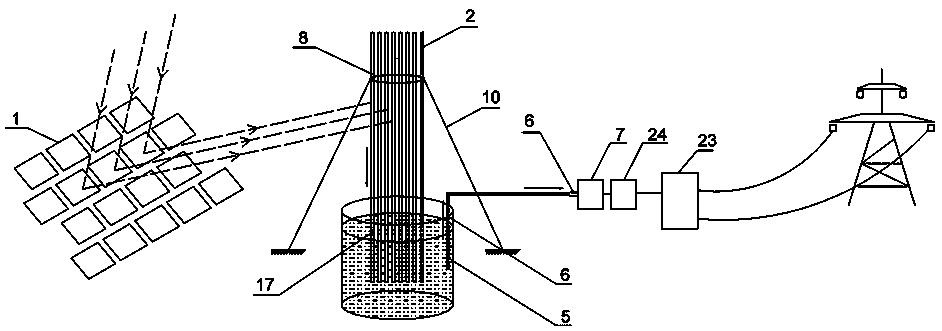

[0027] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

[0028] The direct heat absorption energy storage power generation system based on vacuum heat absorption tubes in the present invention includes a solar thermal power generation system and a solar photovoltaic power generation system.

[0029] Such as Figure 1-4 As shown, the solar thermal power generation system includes a heat collection system for collecting solar heat energy, a heat storage system for storing heat energy, and a power generation system for converting heat energy into electrical energy; the heat collection system includes a plurality of heliosta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com