Foundation pile anti-corrosion system based on action of electric field

A foundation pile and action technology, applied in the field of foundation pile anti-corrosion and foundation pile anti-corrosion system based on the action of electric field, can solve the problems of complex brushing of conductive concrete, inconvenient construction, high use cost, low construction technical requirements and easy maintenance. The effect of low maintenance and construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

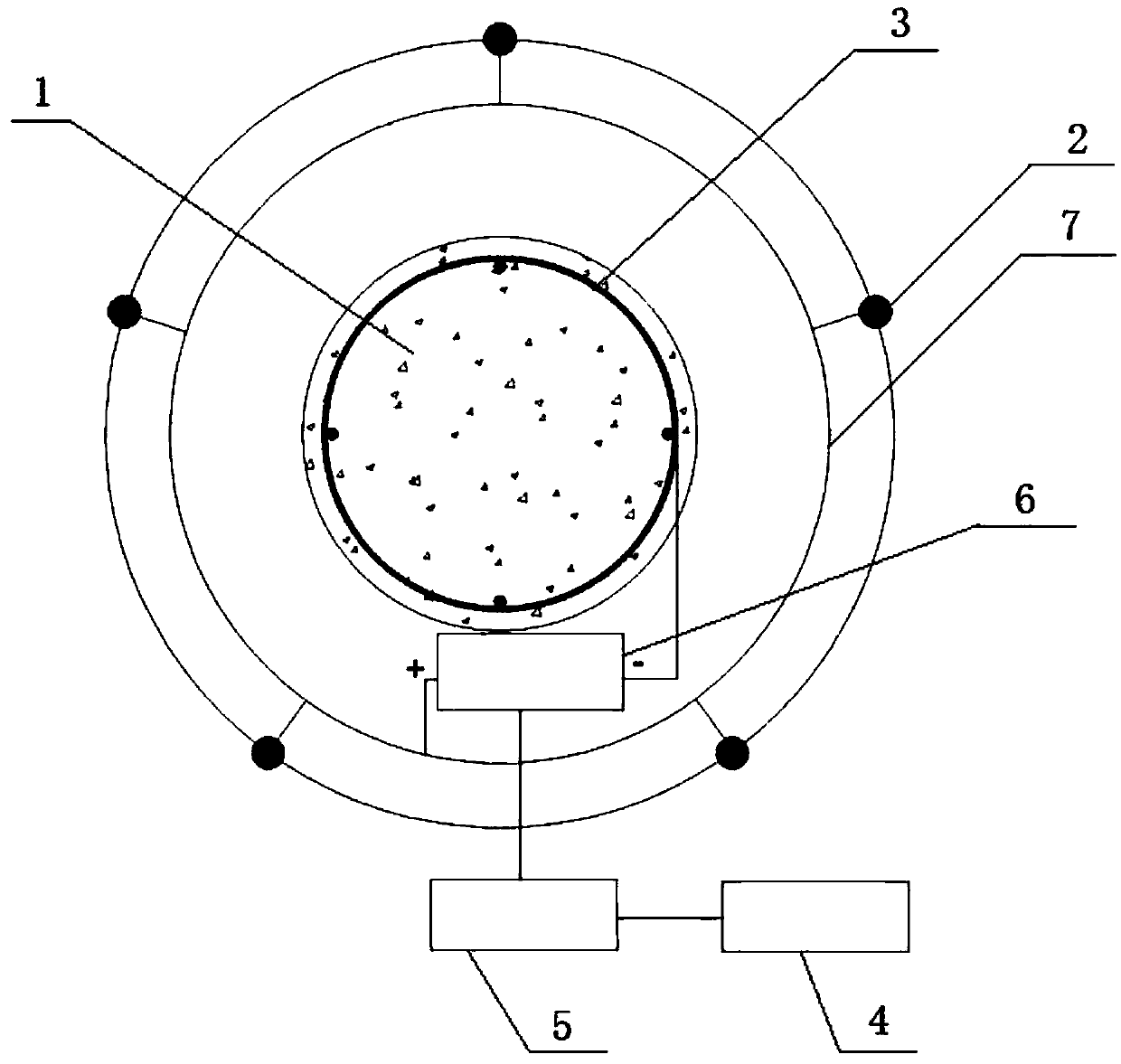

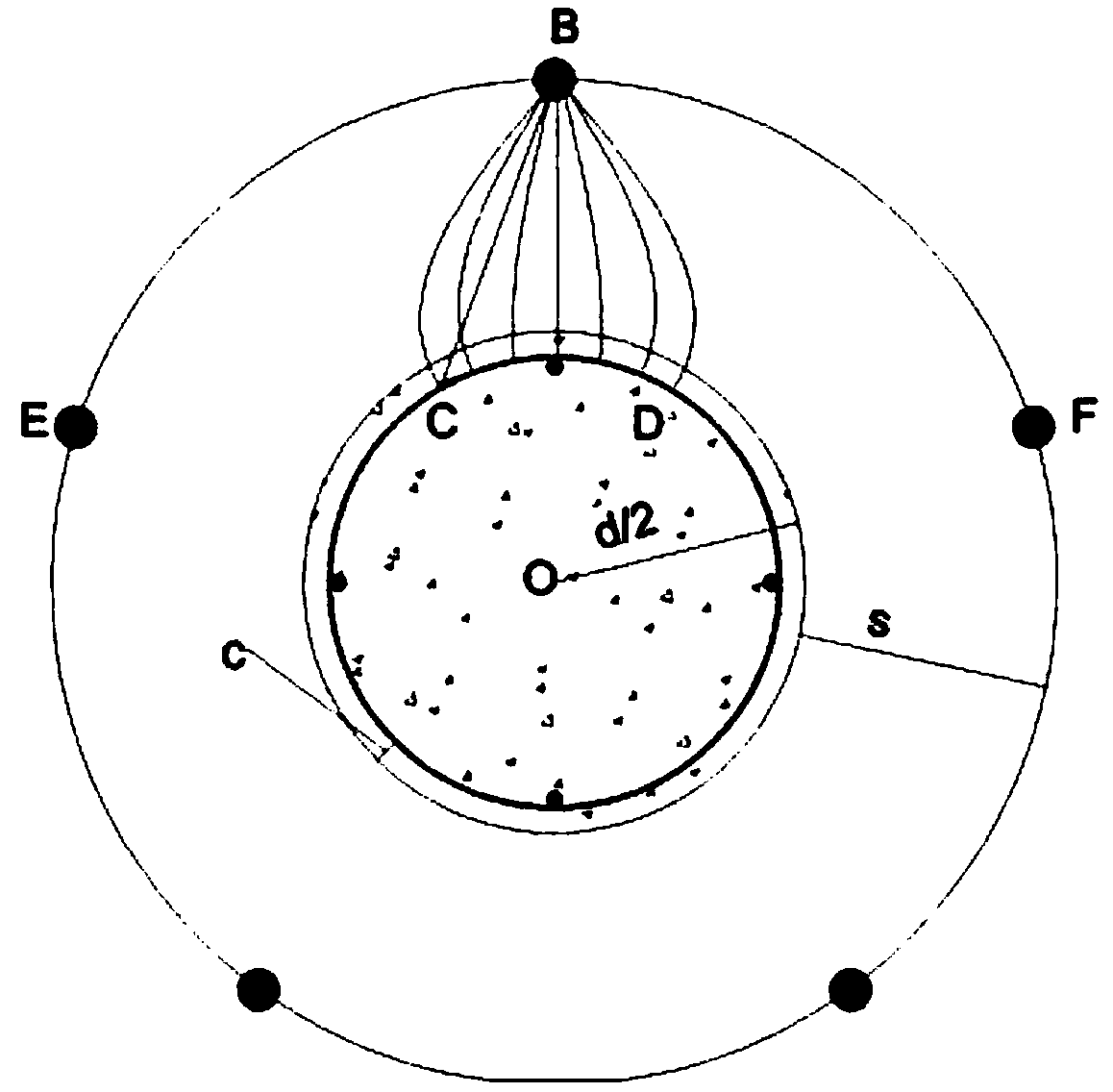

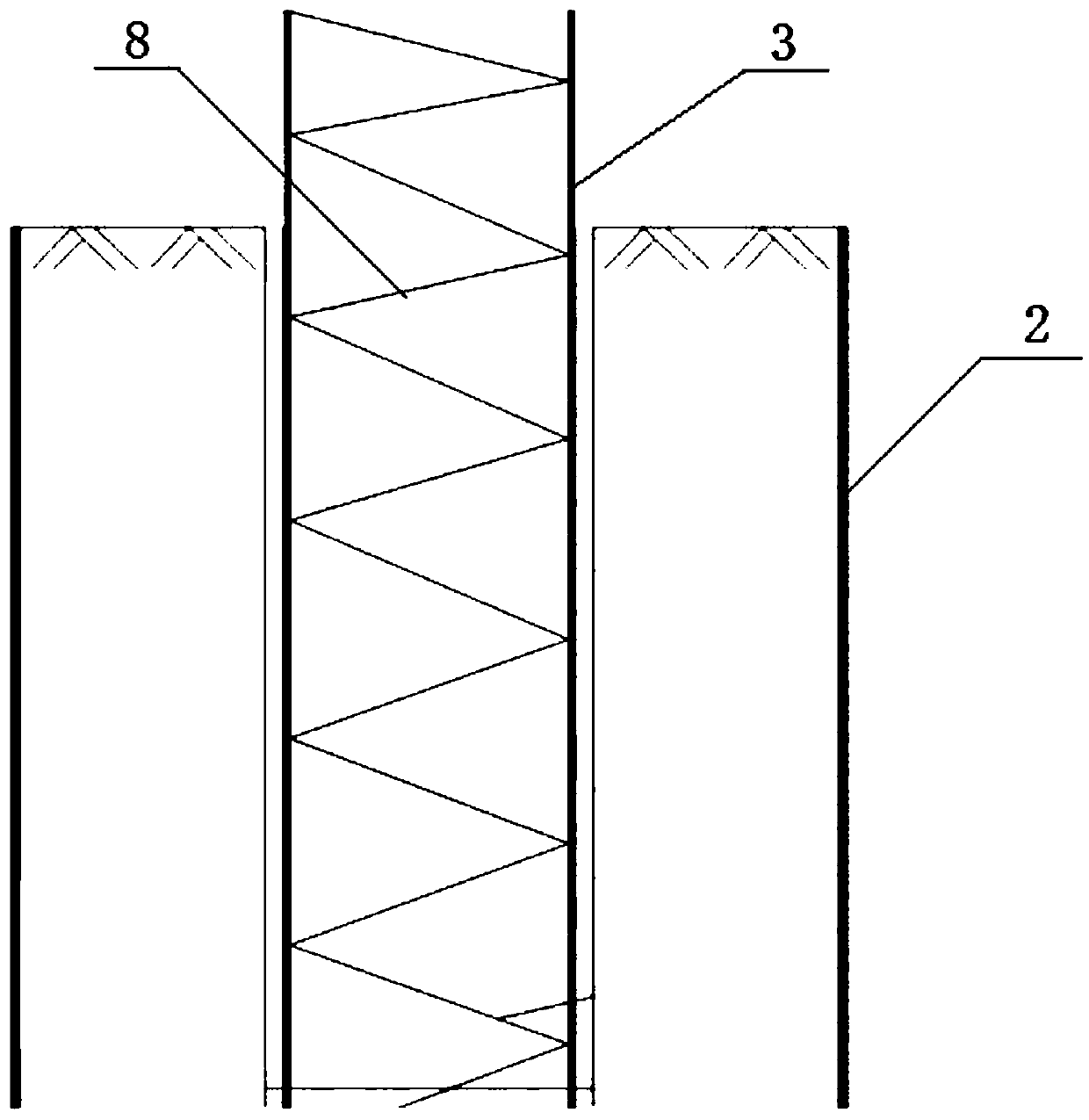

[0057] As a special industrial building, transmission towers are often built on higher ground due to the needs of transmission lines. At present, most of the foundation piles of transmission towers use cast-in-situ piles. Let’s take cast-in-place piles as an example to carry out foundation piles. Anti-corrosion, its structure diagram is as follows image 3 , 4 Shown:

[0058] (1) Wrap the surface of the bundled reinforcement cage 8 with a conductive layer 3 , where high-efficiency aluminum alloy metal mesh with high current efficiency, uniform current distribution, and stable performance can be selected.

[0059] (2) Part of the concrete slurry is first injected into the excavated foundation pit to form a protective layer about 30cm thick at the bottom of the pile. The function is to prevent the bottom of the steel cage wrapped by the aluminum alloy mesh from contacting the soil.

[0060] (3) Put the wrapped reinforcement cage 8 into the pile hole, and then pour concrete to ...

Embodiment 2

[0064] For prefabricated piles, first use conductive paint, which mainly contains conductive graphite powder, and paint the surface of the pile body repeatedly to form a conductive layer. For a concrete layer less than 50mm, ensure that the conductive coating is not affected by moisture in the soil, and then carry out construction according to the construction steps (4) and (5) in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com