Slope Support Method Combining Pre-support and Permanent Support

A technology of permanent support and pre-support, which is applied in excavation, foundation structure engineering, construction, etc., can solve problems such as weak support and over-conservative slope support, achieve restraint of slope deformation, improve construction operability, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing.

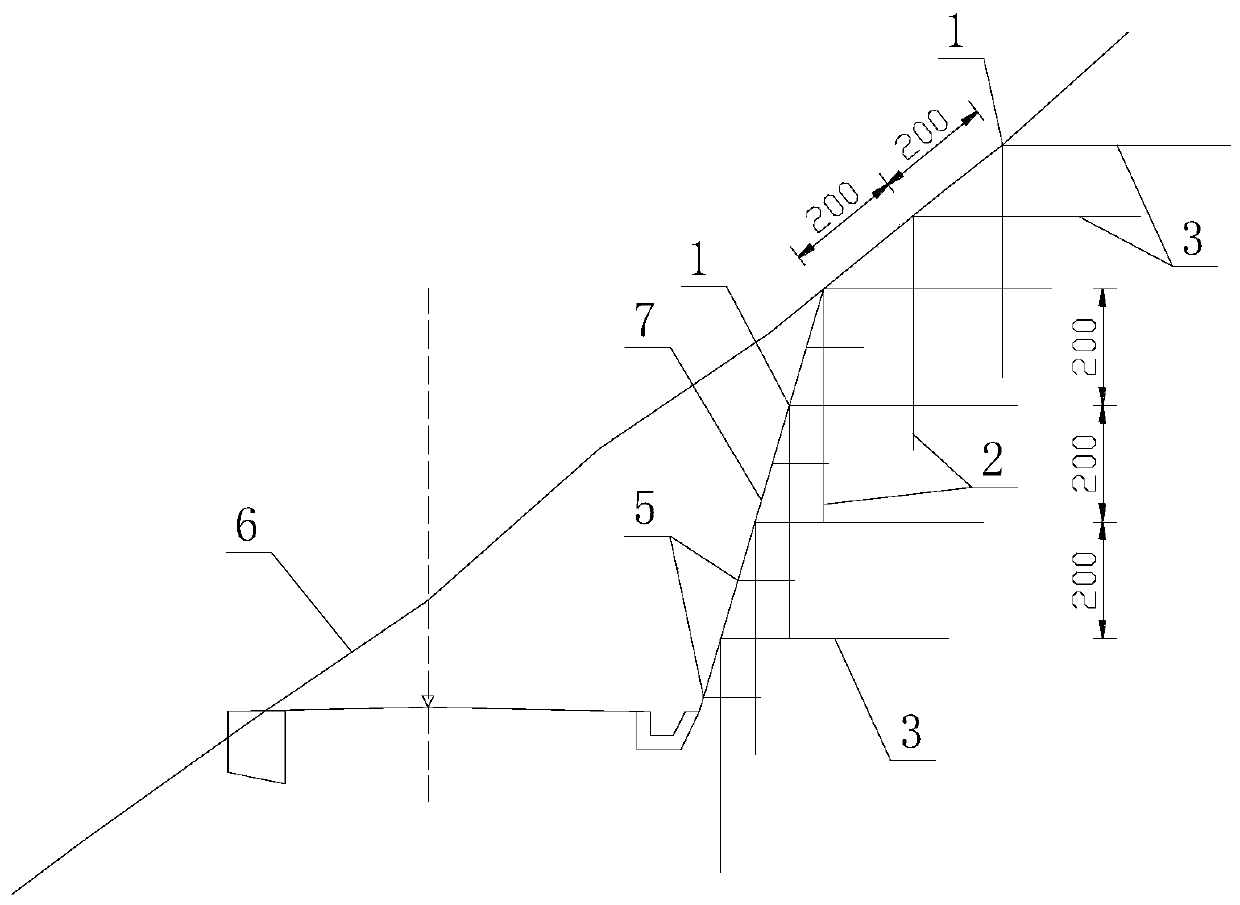

[0047] The present invention includes a slope support method combining pre-support and permanent support, including lock support and slope support, see figure 1 with figure 2 . Among them, the locking support includes the following steps:

[0048] S1. Measure and set the slope opening line. Such as figure 1 , the slope opening line is the line connecting the intersection of the original ground line 6 and the artificial slope line 7, and is located on the top of the artificial slope line 7.

[0049] S2. Outside the opening line of the slope, along the upper side of the natural slope, set at least two rows of bolt arrangement points 1 at intervals. E.g figure 1 Among them, two rows of anchor arrangement points 1 are set at the position marked as 200 along the length of the original ground line 6, and more anchor arrangement points 1 can also be set according to the eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com