Disc type brake pad friction surface coating layer, and production method thereof

A friction surface, disc brake technology, applied in coatings, friction linings, mechanical equipment, etc., can solve the problem of small contact area between brake pads and brake disc, affecting product appearance quality and performance, no friction surface, etc. problems, to improve the appearance quality and the stability and safety of brakes, overcome poor contact, and maintain stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A brush coating on the friction surface of a disc brake pad and its production process. The raw materials of the coating include phenolic resin, iron oxide black and aluminum oxide, and the mass percentages are 200:1:100.5 in sequence;

[0040] The production process of the coating is:

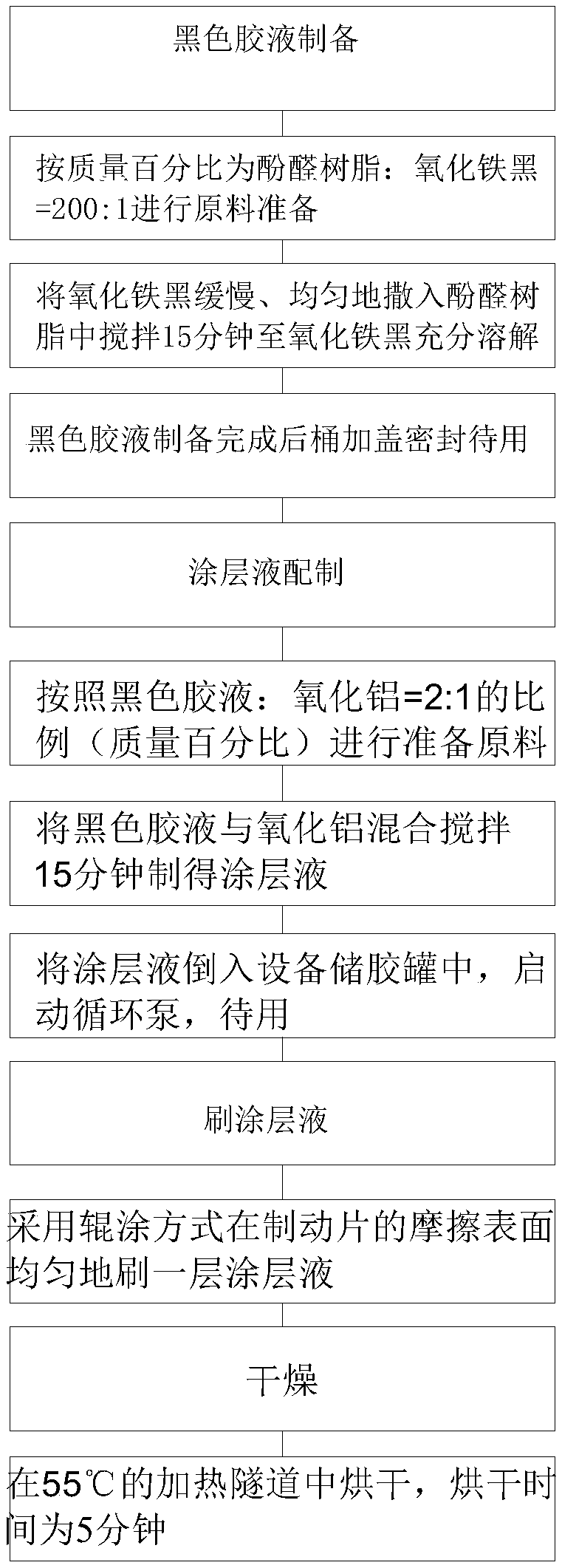

[0041] Step 1: Preparation of black glue

[0042] (1) The black glue solution is prepared from PR-55735 phenolic resin and iron oxide black, and the raw materials are prepared according to the ratio (mass percentage) of phenolic resin:iron oxide black=200:1;

[0043] (2) Sprinkle iron oxide black slowly and evenly into the container filled with phenolic resin, and stir for 15 minutes until iron oxide black is fully dissolved;

[0044] (3) After the preparation is completed, the barrel is sealed and sealed for use;

[0045] Step 2: Preparation of coating solution

[0046] (1) The coating liquid is prepared from the black glue solution and alumina in step 1, and prepares raw materials ...

Embodiment 2

[0052] A brush coating on the friction surface of a disc brake pad and its production process. The raw materials of the coating include phenolic resin, iron oxide black and aluminum oxide, and the mass percentages are 200:1:100.5 in sequence;

[0053] The production process of the coating is:

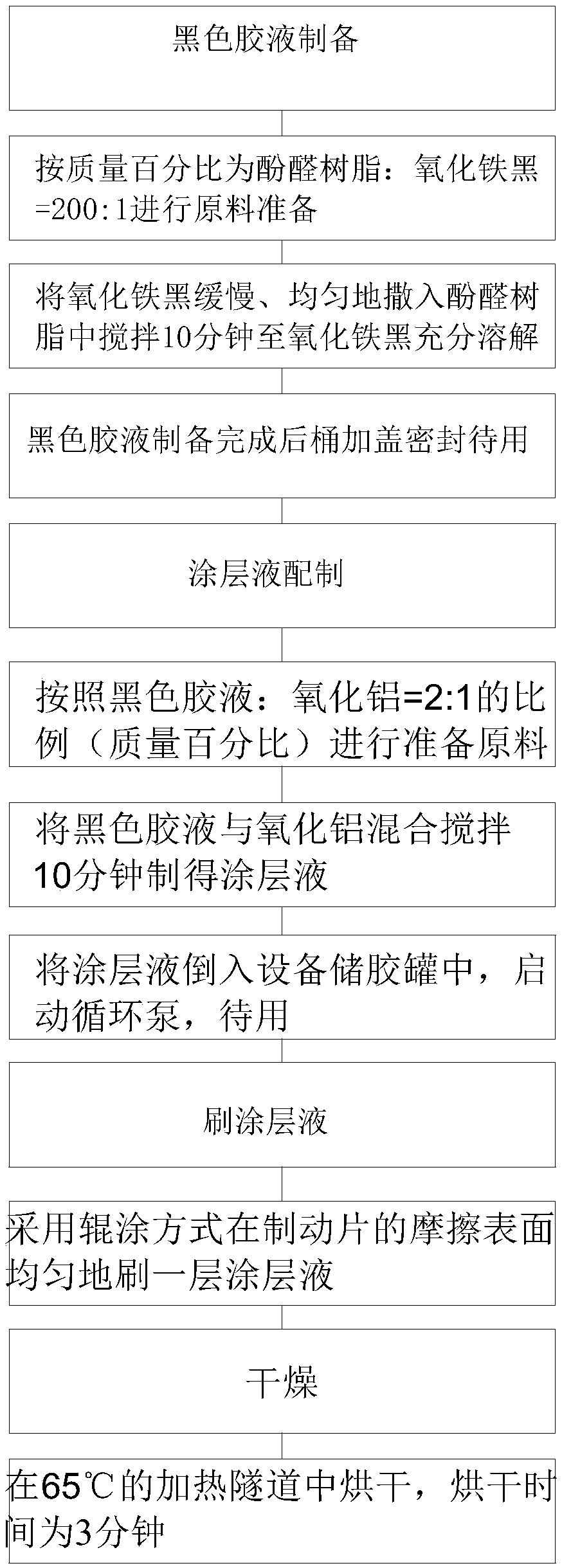

[0054] Step 1: Preparation of black glue

[0055] (1) The black glue solution is prepared from PR-55735 phenolic resin and iron oxide black, and the raw materials are prepared according to the ratio (mass percentage) of phenolic resin:iron oxide black=200:1;

[0056] (2) Sprinkle iron oxide black slowly and evenly into the container filled with phenolic resin, and stir for 10 minutes until iron oxide black is fully dissolved;

[0057] (3) After the preparation is completed, the barrel is sealed and sealed for use;

[0058] Step 2: Preparation of coating solution

[0059] (1) The coating solution is prepared from the black glue solution and alumina in step 1, and the raw materials are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com