Waterborne damping coating used for automobiles

A damping coating, water-based technology, applied in the field of damping coatings, can solve the problems of organic solvent volatilization polluting the environment, flame retardant performance to be improved, damping performance decline, etc., to achieve good salt spray resistance, good heat dissipation performance and anti-corrosion performance, improve The effect of damping properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

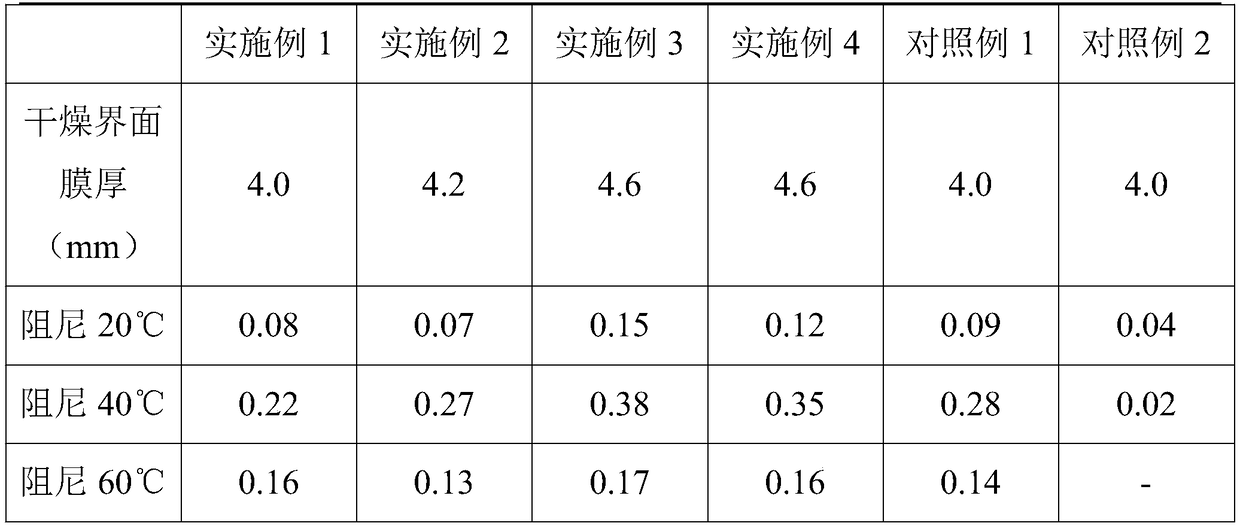

Examples

Embodiment 1

[0027] A water-based damping coating for automobiles, calculated in parts by weight, comprising the following raw materials:

[0028] 50 parts of styrene-acrylate emulsion, 25 parts of polyvinyl alcohol emulsion, 26 parts of polyvinyl acetate emulsion, 60 parts of modified glass powder, 8 parts of modified nano-silicon nitride-silicon dioxide composite particles, liquid environmental protection flame retardant 5 parts, preservative 2 parts, leveling agent 2 parts, lauryl alcohol ester 4 parts, thickener 1.5 parts and deionized water 45 parts.

[0029] The preparation method of modified glass powder:

[0030] Add flake glass powder into acetone, and carry out ultrasonic dispersion to obtain a dispersion liquid. Heat the dispersion liquid to 75°C, then add KH550 and water in turn and stir evenly, and dry it after the reaction is completed. The mass ratio of KH550 to flake glass powder is 1:20.

[0031] The preparation method of the modified nano-silicon nitride-silicon dioxide...

Embodiment 2

[0037] A water-based damping coating for automobiles, calculated in parts by weight, comprising the following raw materials:

[0038] 40 parts of styrene-acrylate emulsion, 30 parts of polyvinyl alcohol emulsion, 20 parts of polyvinyl acetate emulsion, 50 parts of modified glass powder, 4 parts of modified nano-silicon nitride-silicon dioxide composite particles, liquid environmental protection flame retardant 2 parts, 1 part of preservative, 1 part of leveling agent, 2 parts of dipropylene glycol monomethyl ether, 0.5 part of thickener and 30 parts of deionized water.

[0039] The preparation method of the modified nano-silicon nitride-silicon dioxide composite particles is as follows: adding nano-silicon nitride powder into the alkaline silica sol, adjusting the pH to 5.6 with oxalic acid, stirring and dispersing to obtain a silicon nitride suspension dispersion; Add the ethanol solution of polyamide and silane coupling agent KH550 dropwise to the silicon nitride suspension ...

Embodiment 3

[0043] A water-based damping coating for automobiles, calculated in parts by weight, comprising the following raw materials:

[0044] 60 parts of styrene-acrylate emulsion, 20 parts of polyvinyl alcohol emulsion, 30 parts of polyvinyl acetate emulsion, 70 parts of modified glass powder, 10 parts of modified nano-silicon nitride-silicon dioxide composite particles, liquid environmental protection flame retardant 5 parts, preservative 3 parts, leveling agent 3 parts, propylene glycol methyl ether acetate 5 parts, thickener 2 parts and deionized water 60 parts.

[0045] The preparation method of the modified nano-silicon nitride-silicon dioxide composite particles is as follows: adding nano-silicon nitride powder into the alkaline silica sol, adjusting the pH to 6.0 with oxalic acid, stirring and dispersing to obtain a silicon nitride suspension dispersion; Add the ethanol solution of polyamide and silane coupling agent KH550 dropwise to the silicon nitride suspension dispersion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com