Preparation method of aminomethylbenzoic acid

A technology of aminotoluic acid and aminomethylbenzoic acid, which is applied in the preparation of organic compounds, chemical instruments and methods, and cyanide reaction preparation, etc., can solve the problems of many by-products, complicated preparation process, and low product yield. Achieve the effects of less by-products, simple production process and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method of aminotoluic acid in the embodiment of the present invention comprises:

[0027] The 4-chloromethylbenzoic acid that takes 40g is dissolved in the methanol of 1100g, obtains mixed solution;

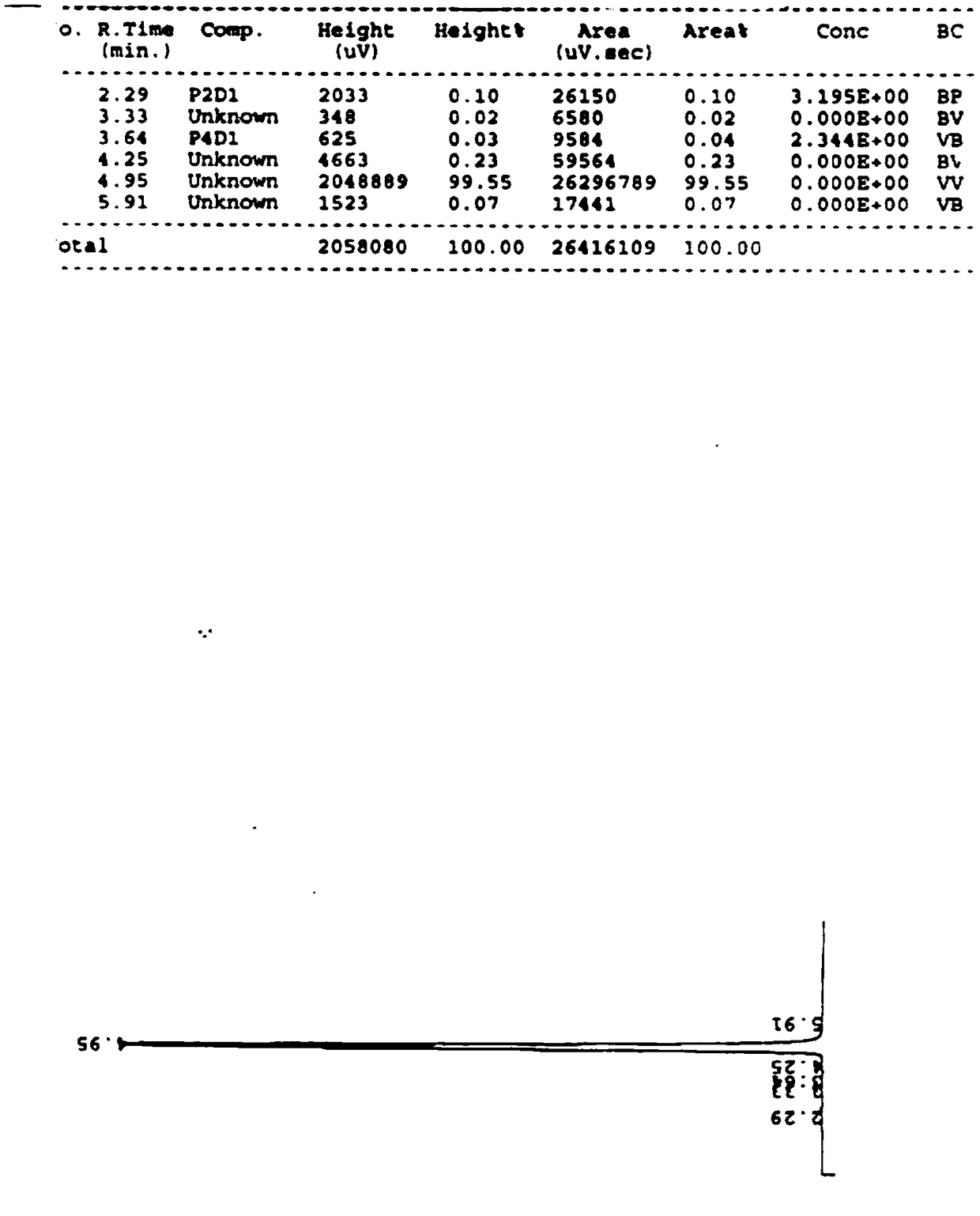

[0028] Add 70g of strong ammonia water (mass fraction is 25%) in mixed solution, control temperature is 60 ℃, and working pressure is 0.3Mpa, carries out reaction 4h in titanium material reaction container, makes 4-chloromethylbenzoic acid change into 4 -aminomethylbenzoic acid, obtain aminomethylbenzoic acid after vacuum filtration, figure 1 It is the high-performance liquid chromatogram (HPLC) of the aminotoluic acid gained in Example 1, as can be seen from the figure, the purity of aminotoluic acid in the resulting product reaches 99.51%, and the retention time is 4.94min. Sample analysis unit: Hunan Dongting Pharmaceutical Industry limited company.

[0029] Chemical reaction process of the present invention is:

[0030]

Embodiment 2

[0032] A kind of preparation method of aminotoluic acid in the embodiment of the present invention comprises:

[0033] The 4-chloromethylbenzoic acid that takes 50g is dissolved in the methanol of 900g, obtains mixed solution;

[0034] Add 80g of concentrated ammonia water (mass fraction is 28%) in mixed solution, control temperature is 80 ℃, and working pressure is 0.5Mpa, carries out reaction 1h in titanium material reaction vessel, makes 4-chloromethylbenzoic acid change into 4 -aminomethylbenzoic acid, obtain aminomethylbenzoic acid after vacuum filtration, figure 2 It is the high-performance liquid chromatogram (HPLC) of the aminotoluic acid obtained in Example 2, as can be seen from the figure, the purity of aminotoluic acid in the resulting product reaches 99.55%, and the retention time is 4.93min. Sample analysis unit: Hunan Dongting Pharmaceutical Industry limited company.

Embodiment 3

[0036] A kind of preparation method of aminotoluic acid in the embodiment of the present invention comprises:

[0037] The 4-chloromethylbenzoic acid that takes 35g is dissolved in the methanol of 1300g, obtains mixed solution;

[0038] Add the strong ammoniacal liquor (massfraction is 26%) of 60g in mixed solution, control temperature is 40 ℃, and working pressure is 0.2Mpa, carries out reaction 5h in glass-lined reaction vessel, makes 4-chloromethylbenzoic acid change into 4 -aminomethylbenzoic acid, obtain aminomethylbenzoic acid after vacuum filtration, image 3 It is the high-performance liquid chromatogram (HPLC) of embodiment 3 gained aminotoluic acid, as can be seen from the figure, the purity of aminotoluic acid in the obtained product reaches 99.55%, and retention time is 4.95min, sample analysis unit: Hunan Dongting Pharmaceutical Industry limited company.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com