Composite fluorine removal agent and preparation method thereof

A defluoridation agent and composite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of low utilization rate and poor defluoridation effect, and achieve high utilization rate and inorganic pollution Small amount of mud, good defluoridation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The invention discloses a composite type defluoridation agent, which is prepared from the following components according to the mass percentage: 70.00% of calcium salt, 15.80% of water, 5.5% of water glass, 2.00% of acid, 1.50% of iron salt, and 5.00% of aluminum salt %, polydimethyldiallylammonium chloride 0.20%.

[0023] The preparation method of composite type defluorination agent of the present invention is completed by the following steps:

[0024] (1), inject 3500kg 30% liquid calcium chloride into 5 cubic enamel reaction kettle, add water 790kg, stir for 5min, fully mix evenly;

[0025] (2), continue to add hydrochloric acid 100kg to above-mentioned reactor, stir 5min, fully mix;

[0026] (3), step (2) under agitation state, cast ferrous chloride tetrahydrate 75kg continuously, stir 5min, fully dissolve;

[0027] (4), step (3) in the stirring state, continue to add 250 kg of anhydrous aluminum chloride, stir for 20 minutes, fully dissolve, and control the heati...

Embodiment 2

[0032] The invention discloses a composite type defluoridation agent, which is prepared from the following components according to the mass percentage: calcium salt 68.20%, water 17.00%, water glass 6.5%, acid 3.00%, iron salt 1.00%, aluminum salt 4.00% %, polydimethyldiallylammonium chloride 0.30%.

[0033] The calcium salt is 30% liquid calcium chloride, the acid is hydrochloric acid, the iron salt is ferrous chloride tetrahydrate, and the aluminum salt is anhydrous aluminum chloride.

[0034] The present invention also discloses a preparation method of the above-mentioned composite defluorinating agent, the specific steps are as follows:

[0035] (1), according to the above mass percentage, inject calcium salt into the enamel reaction kettle, add water, stir for 7 minutes, and fully mix evenly;

[0036] (2), continue to add acid in above-mentioned reactor, stir 7min, fully mix evenly;

[0037] (3), under the stirring state of step (2), drop into iron salt continuously, st...

Embodiment 3

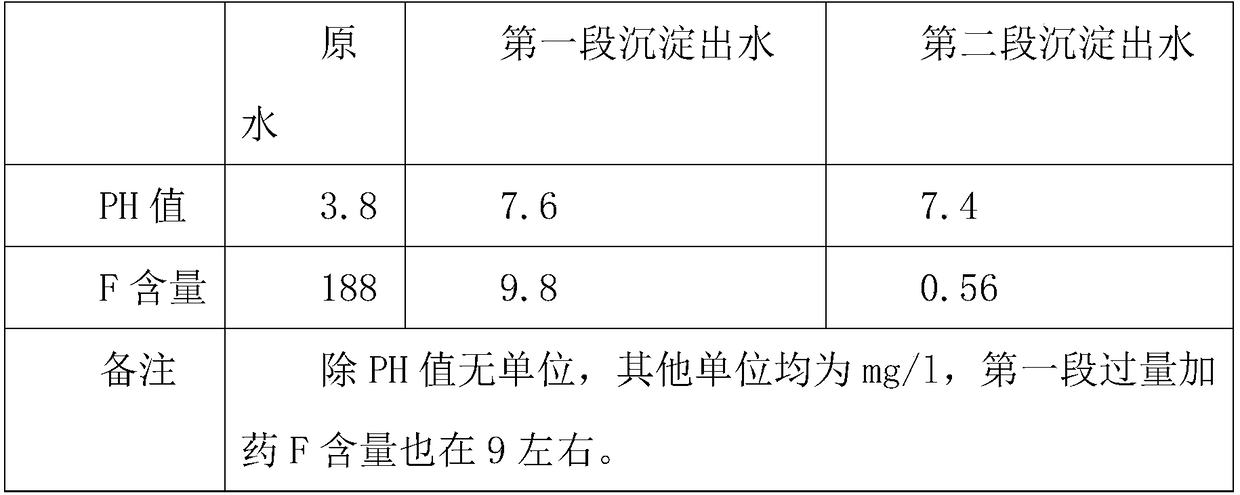

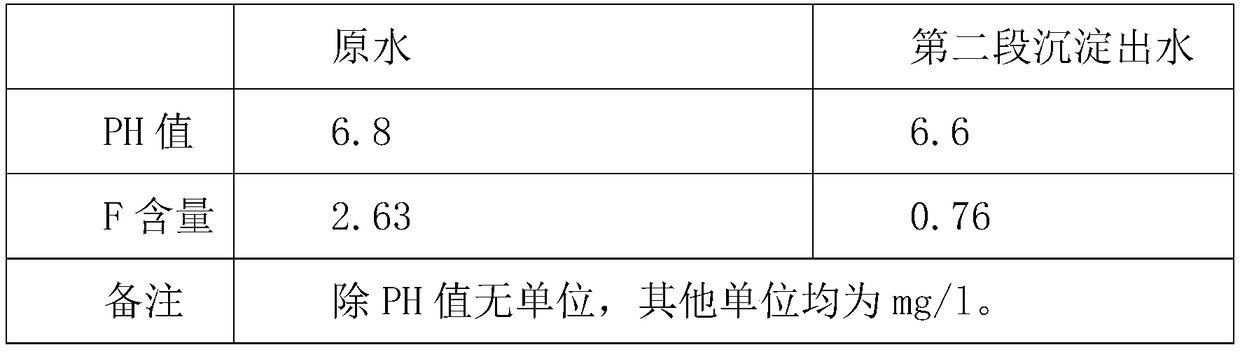

[0046] Taking the actual application of fluorine-containing wastewater in a glass factory in Shenzhen as an example, the sewage station of the glass factory adopts a two-stage fluoride removal process. The first stage uses calcium chloride + calcium hydroxide + polyaluminum chloride + anionic polyacrylamide precipitation, the second The second stage uses the composite defluorinating agent prepared in Example 1 + anionic polyacrylamide precipitation, and the processing data are as follows in Table 1:

[0047] Table 1

[0048]

[0049] It can be known from Table 1 that the composite defluoridation agent prepared by the present invention has a better defluorination effect in wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com