Silk screen printing equipment suitable for batch processing and realizing even ink distribution

A uniformly distributed, screen printing technology, applied in screen printing, screen printing machines, printing, etc., can solve the problems of inconvenient replacement of screens, inability to guarantee ink leakage, etc., and achieve good printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

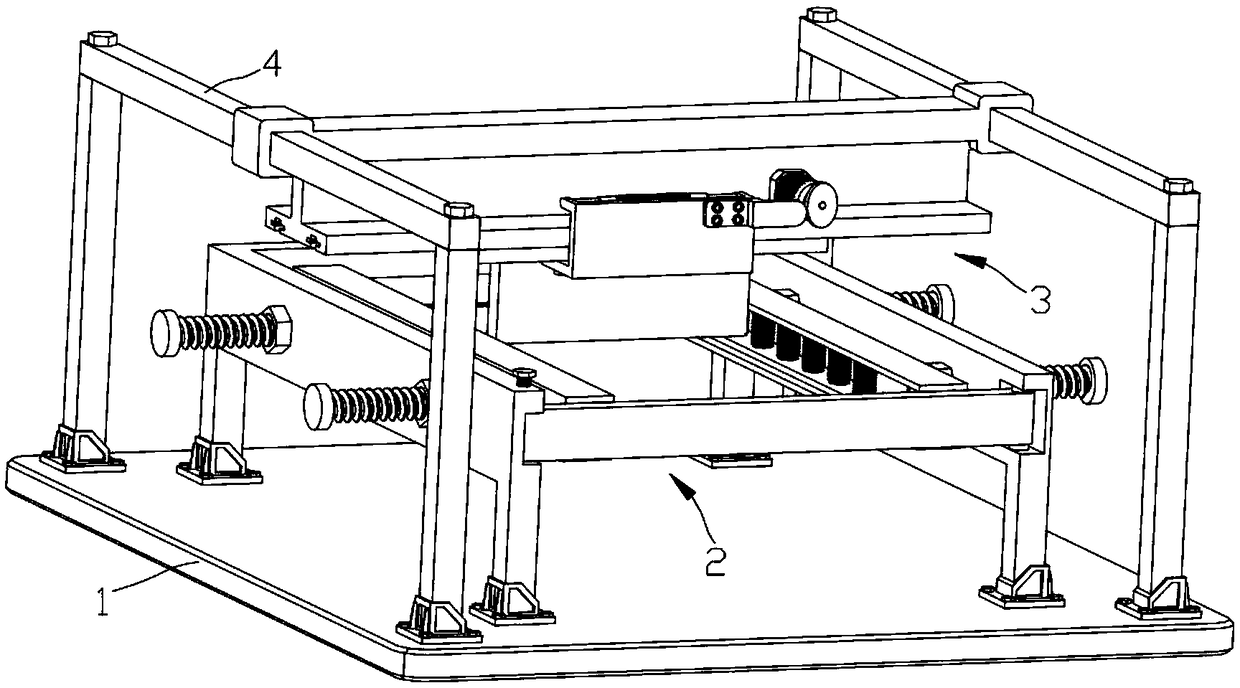

[0023] see Figure 1 to Figure 5 , the present invention provides a technical solution:

[0024] A screen printing device suitable for batch processing with uniform ink distribution, comprising a bottom plate 1, a screen fixing mechanism 2, an ink application mechanism 3 and a pneumatic guide rail 4, characterized in that:

[0025] The two pneumatic guide rails 4 are respectively fixedly installed on the base plate 1 through the supporting legs and the two pneumatic guide rails 4 are placed opposite each other, wherein the pneumatic guide rail 4 is externally connected with an air pressure source;

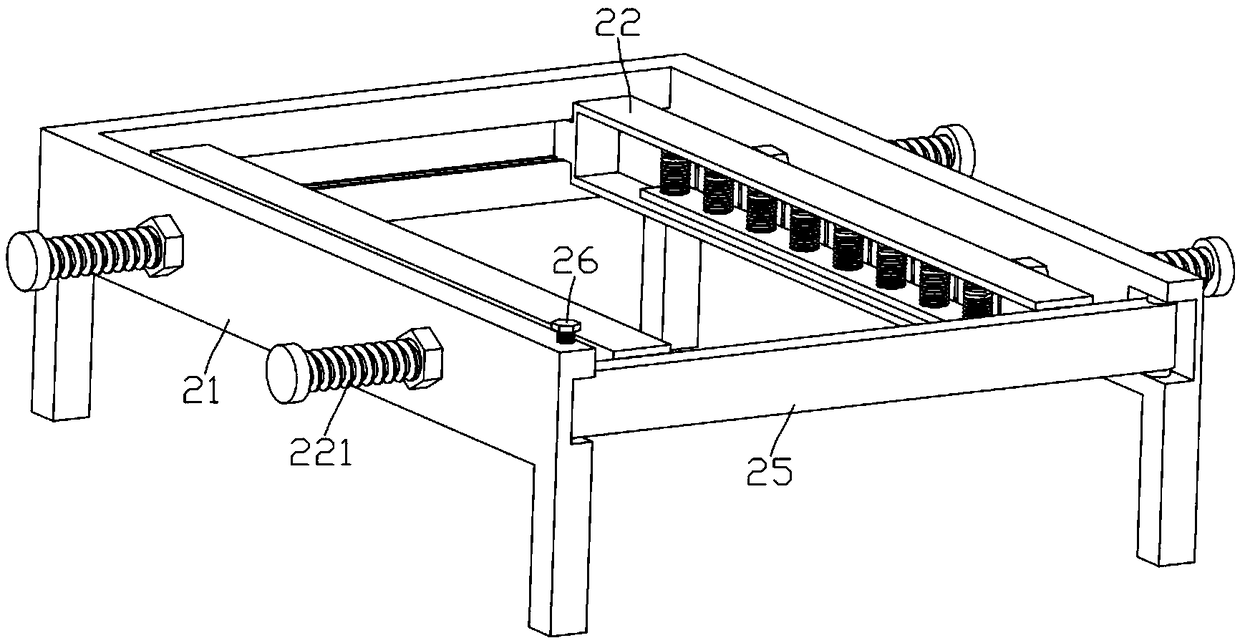

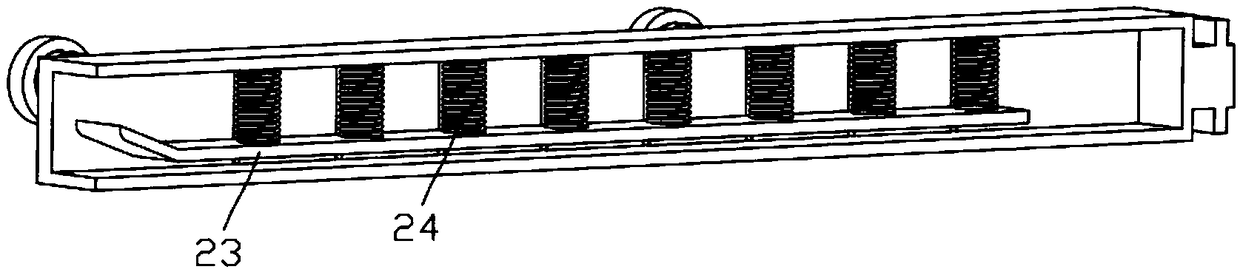

[0026] The wire mesh fixing mechanism 2 includes a support frame 21, a frame 22, a splint 23, a connecting spring 24, a baffle plate 25 and a fastening bolt 26. The support frame 21 is fixedly installed on the base plate 1 by bolts, and the two frames 22 are respectively mounted on the supporting frame. frame 21 and forms a mobile pair in the support frame 21, wherein two frames 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com