Patrolling robot mechanical arm tail end space positioning method

An inspection robot and spatial positioning technology, which is applied to manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high cost of distance sensors and low positioning accuracy, so as to avoid low accuracy, reduce positioning costs, and improve spatial positioning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

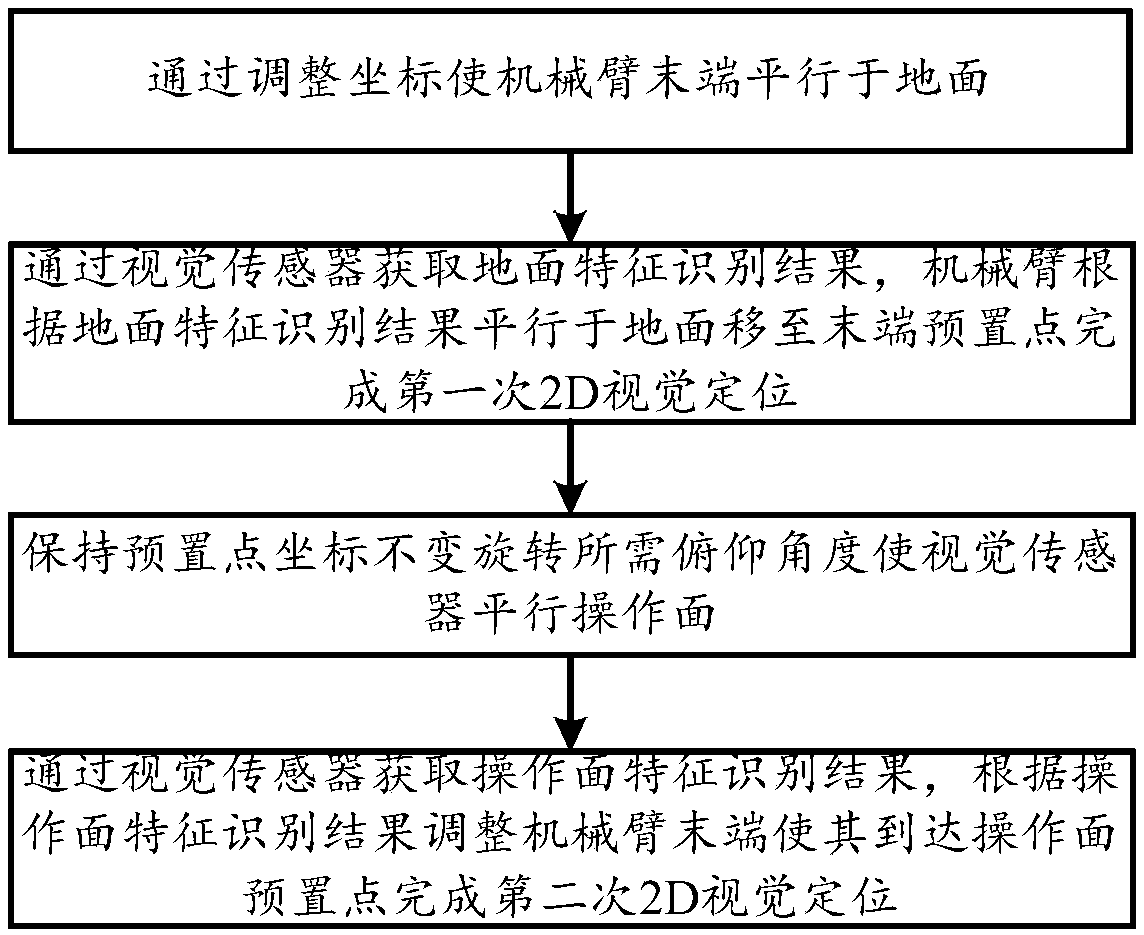

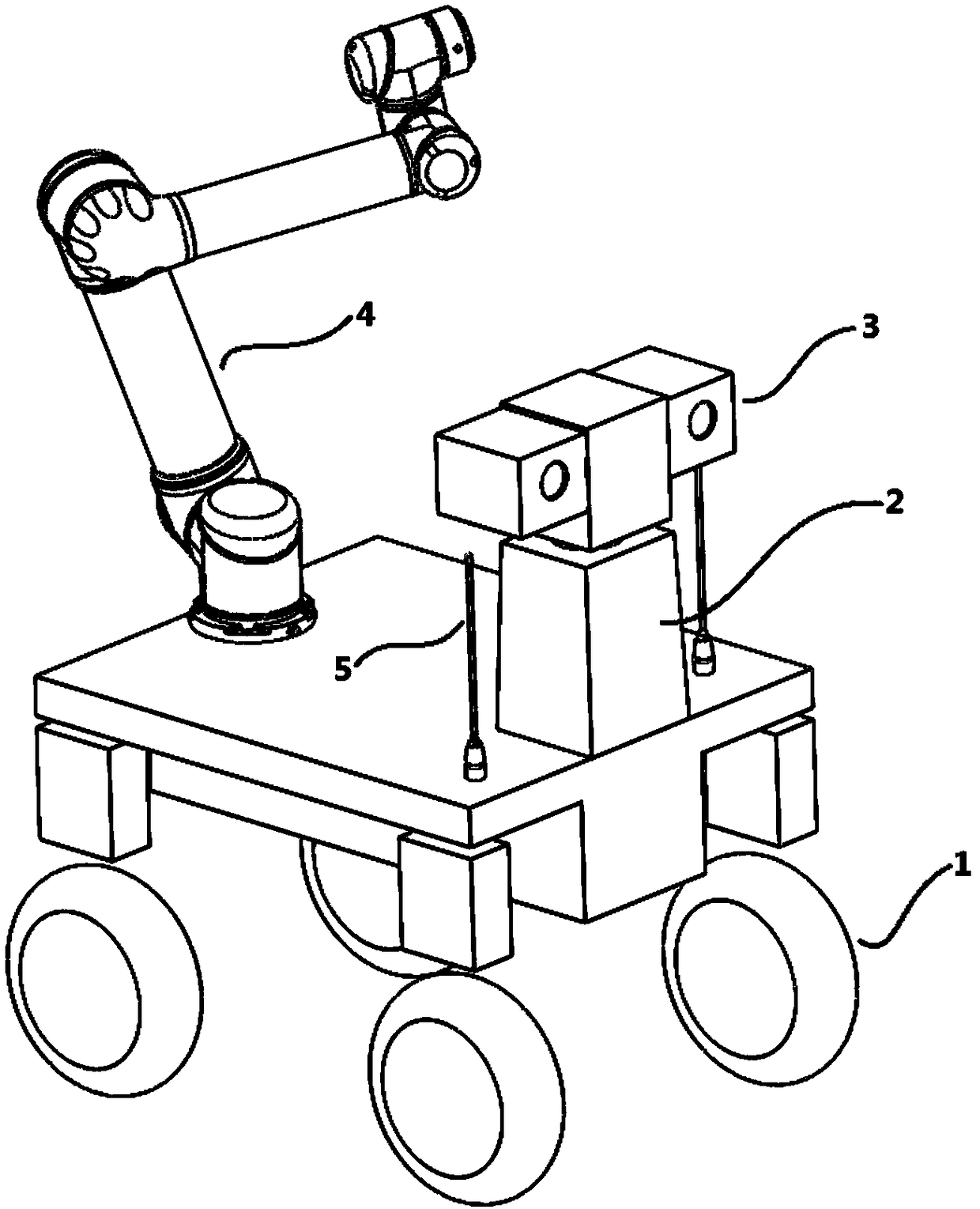

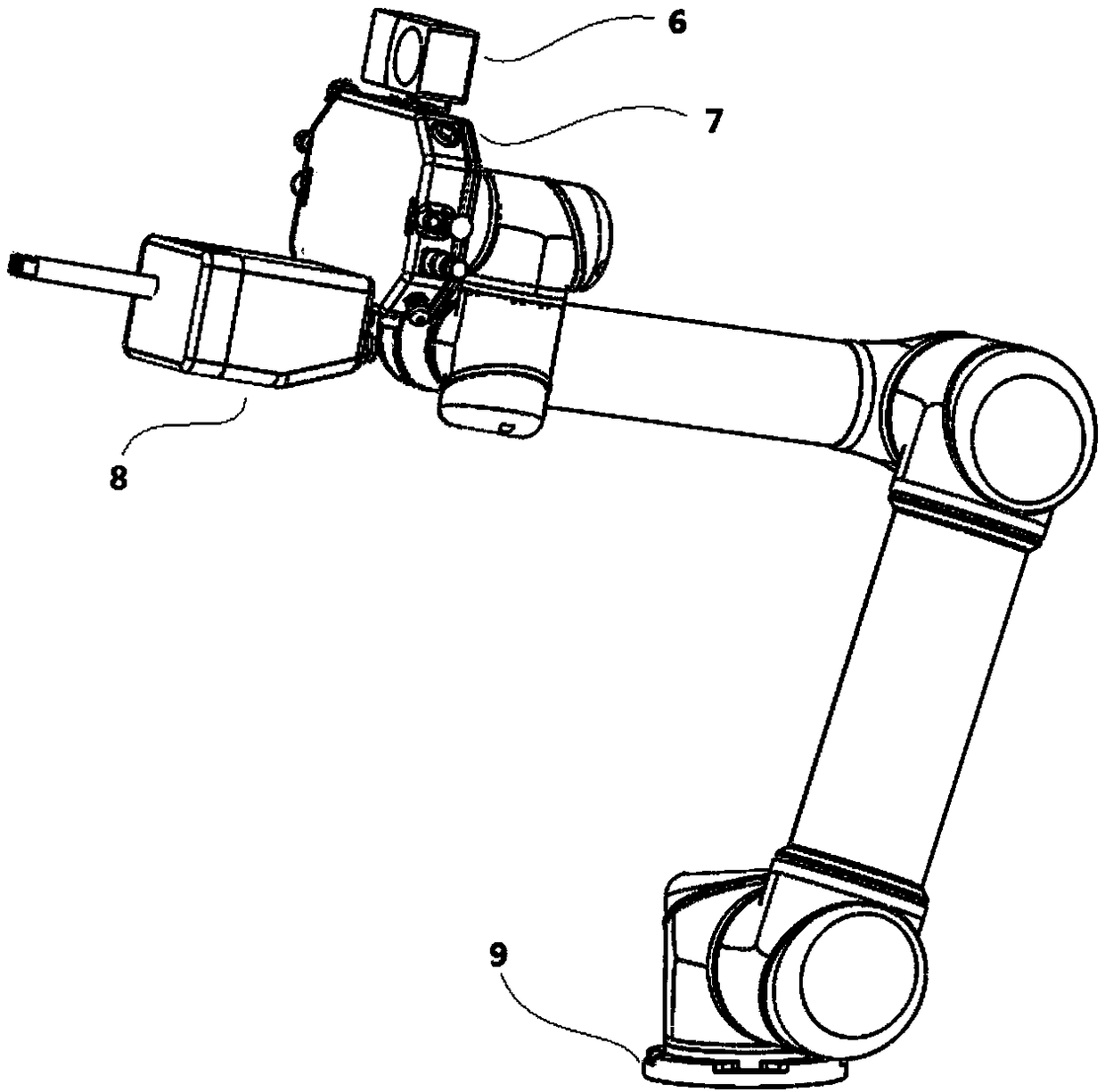

[0045] The inspection robot needs to open the switchgear 11. The inspection robot uses laser radar to navigate to the vicinity of the operated equipment. Due to the navigation accuracy and motion control accuracy, there is a deviation between the actual position and the preset position. First, adjust the most terminal joint of the mechanical arm, keep the rotation vector along the Y axis of the end, that is, Ry=0°, and the rotation vector along the X axis, that is, Rx=90°, so that the visual sensor is parallel to the ground, that is, parallel to the XOY plane; if the above The coordinate system is not Figure 4As shown, it is necessary to make corresponding adjustments according to the setting of the coordinates so that it is adjusted parallel to the ground; then, the visual sensor recognizes the ground features 10 entered into the system in advance; Perform translation. During the movement, the height of the end of the robotic arm is a constant value, and the attitude angle i...

Embodiment 2

[0047] Based on Example 1, if the operation surface is on the right side of the robot, the pitch angle is selected to be 270 degrees, and the terminal visual sensor is rotated 270 degrees clockwise to be parallel to the operation surface; or the pitch angle is selected to be 90 degrees, and the terminal visual sensor is rotated 90 degrees counterclockwise. parallel operating surfaces. Select different angles for positioning according to the position of the operation surface and the robot arm, avoiding errors caused by position differences, and further improving the spatial positioning accuracy of the end of the robot arm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap