Automatic sorting device and sorting method of elongated and flaky particles of coarse aggregate for road surface

An automatic sorting, needle-like technology, applied in chemical instruments and methods, separation of solids from solids by air flow, solids separation, etc., can solve difficult to meet modern road construction needs, high temperature stability of asphalt mixture Reduced, no effective sorting device for needle-like aggregates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

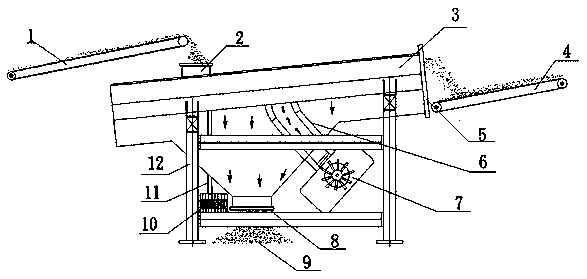

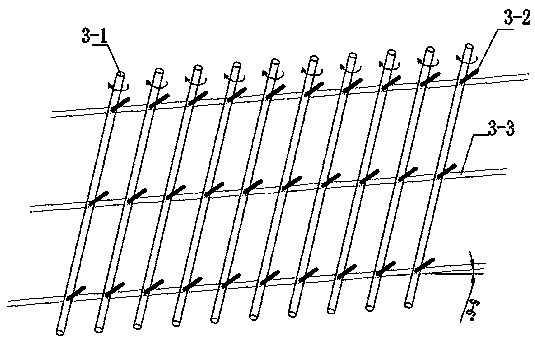

[0025] Such as figure 1 , figure 2 As shown, the pavement automatic sorting device for coarse aggregate needle flake particles of the specific embodiment includes a feed port 2, a stepped sieve plate 3, a blower 7, an air guide pipe 6, a vibrating motor 10, and a dowel bar 11 , miscellaneous outlet 5, outlet 8, qualified aggregate pile 9 and frame 12. Conveyor belts 1 and 4 are the working environment in this specific embodiment, namely the conveyer belt 1 on the left side of the device will transport the unsorted aggregates to the feed inlet for sorting, and the conveyer belt 4 on the right side of the device will be sorted. The selected needle-like aggregates are transported to other places. Because the conveyor belt is an external condition, the specific implementation method does not require the specification and power of the conveyor belt. The experiment assum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com