A kind of steel slag aggregate production method

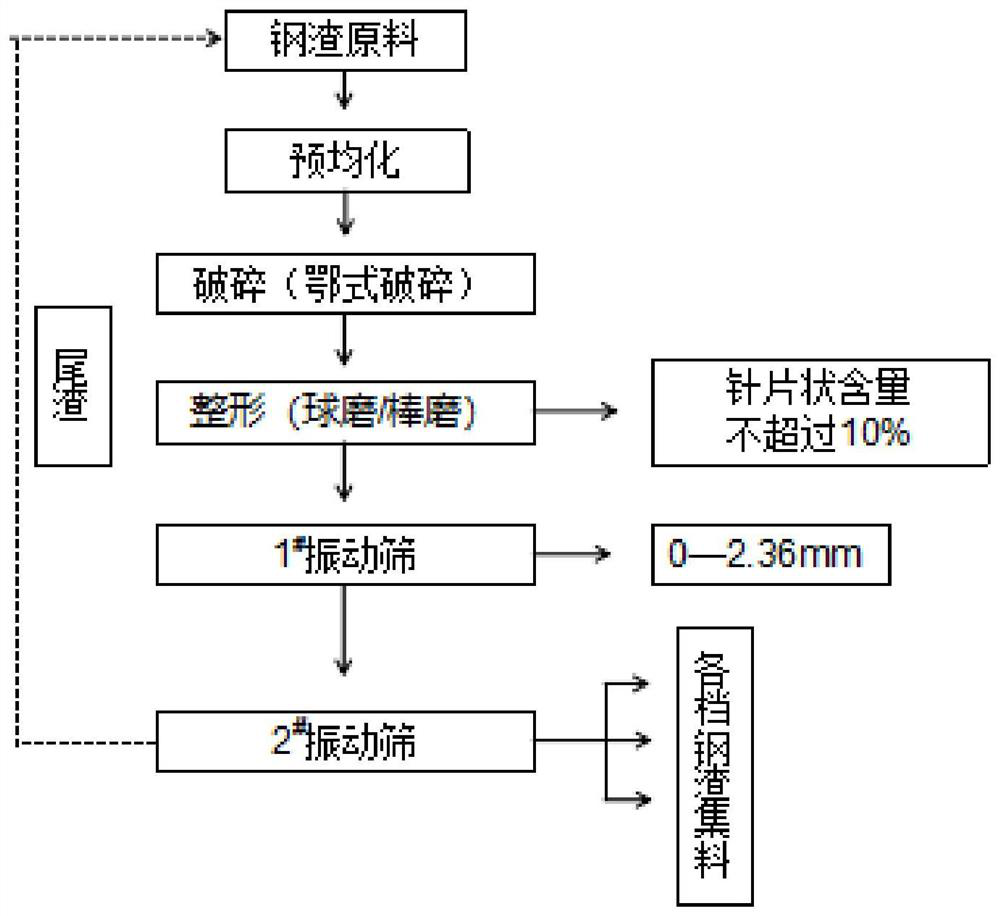

A production method and technology for slag aggregates, which are applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of large specification variability and lack of angularity, and achieve the reduction of needle flake content, Improve angularity and increase the effect of particle shaping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Take the steel slag of a large iron and steel enterprise as the raw material, and carry out processing and production according to this production process. The main process parameters used are as follows:

[0047] Number of unloading bins 4 Radius of discharge opening (mm) 75 Discharge flow rate (m / s) 1.2 T delay (s)

[0048] The yield of the product obtained in this example (the sum of each grade of aggregates, excluding the 0-3mm part) is about 70%. 10 samples of steel slag aggregate were randomly sampled, the average content of needle flakes in the aggregate was 9.2%, and the coefficient of variation was 5.08%.

Embodiment 2

[0050] Take the steel slag of a large iron and steel enterprise as the raw material, and carry out processing and production according to this production process. The main process parameters used are as follows:

[0051] Number of unloading bins 5 Radius of discharge opening (mm) 90 Discharge flow rate (m / s) 1.6 T delay (s)

[0052] The yield of the product obtained in this example (the sum of all grades of aggregates, excluding the 0-3mm part) is about 67%. 10 samples of steel slag aggregates were randomly sampled, and the average content of needle flakes in the aggregates was 8.3%, and the coefficient of variation was 8.10%.

Embodiment 3

[0054] Take the steel slag of a large iron and steel enterprise as the raw material, and carry out processing and production according to this production process. The main process parameters used are as follows:

[0055] Number of unloading bins 6 Radius of discharge opening (mm) 100 Discharge flow rate (m / s) 2.0 T delay (s)

7 Shaping time (s) 40

[0056] The yield of the product obtained in this example (the sum of each grade of aggregates, excluding the 0-3 mm part) is about 65%. 10 samples of steel slag aggregates were randomly sampled, and the average content of needle flakes in the aggregates was 8.0%, and the coefficient of variation was 5.60%.

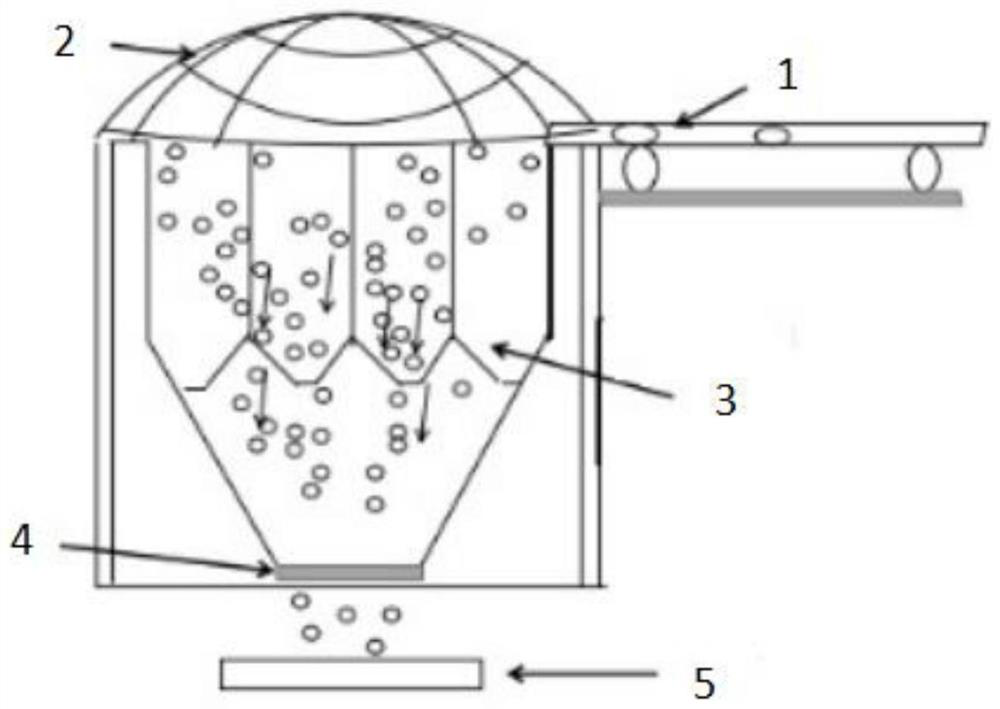

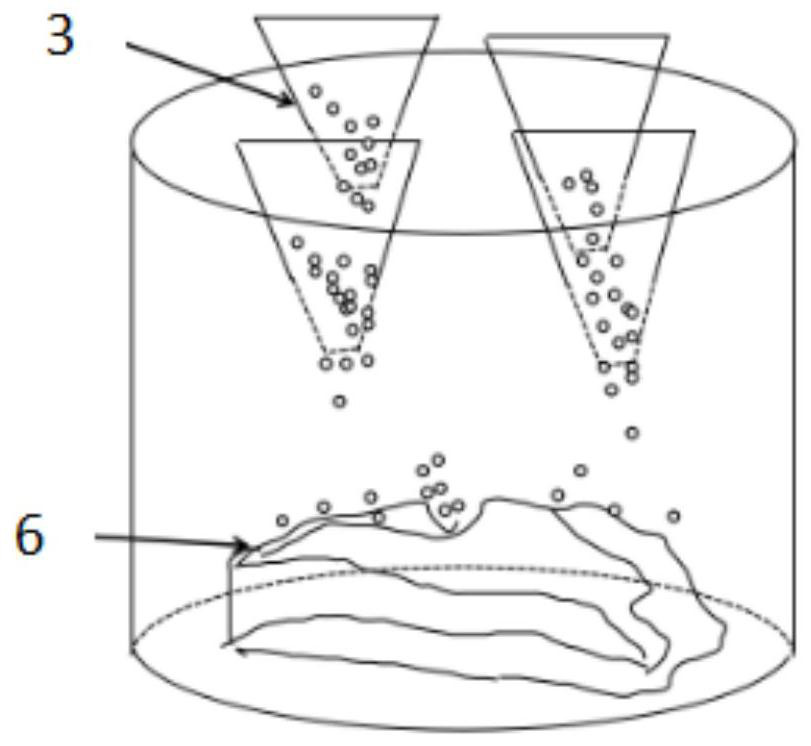

[0057] In the method for producing steel slag aggregate in the present invention, multiple batches of steel slag raw materials are uniformly mixed through a pre-homogenization process. In the pre-homogenization process provided by the present invention, by designing the structure of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com