Multi-point contact finger and electrical connector

A multi-point contact and contact finger technology, applied in the direction of contact parts, etc., can solve the problems of inability to meet the use environment, limit the rated current capacity of electrical connectors, etc., to improve the rated current capacity, increase electrical performance, and ensure mechanical use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

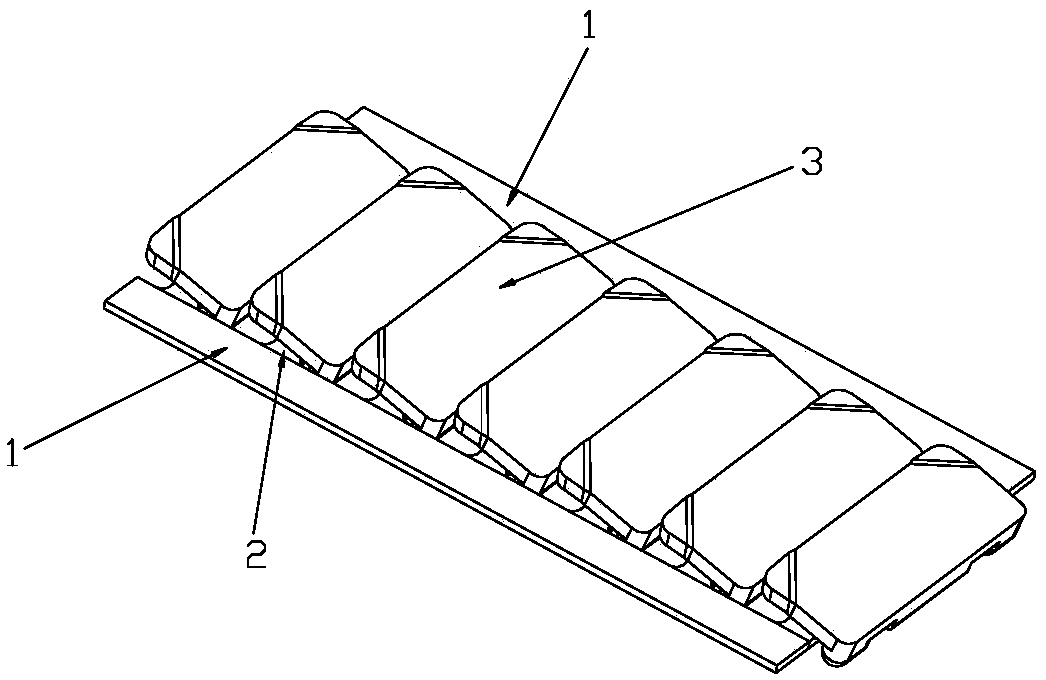

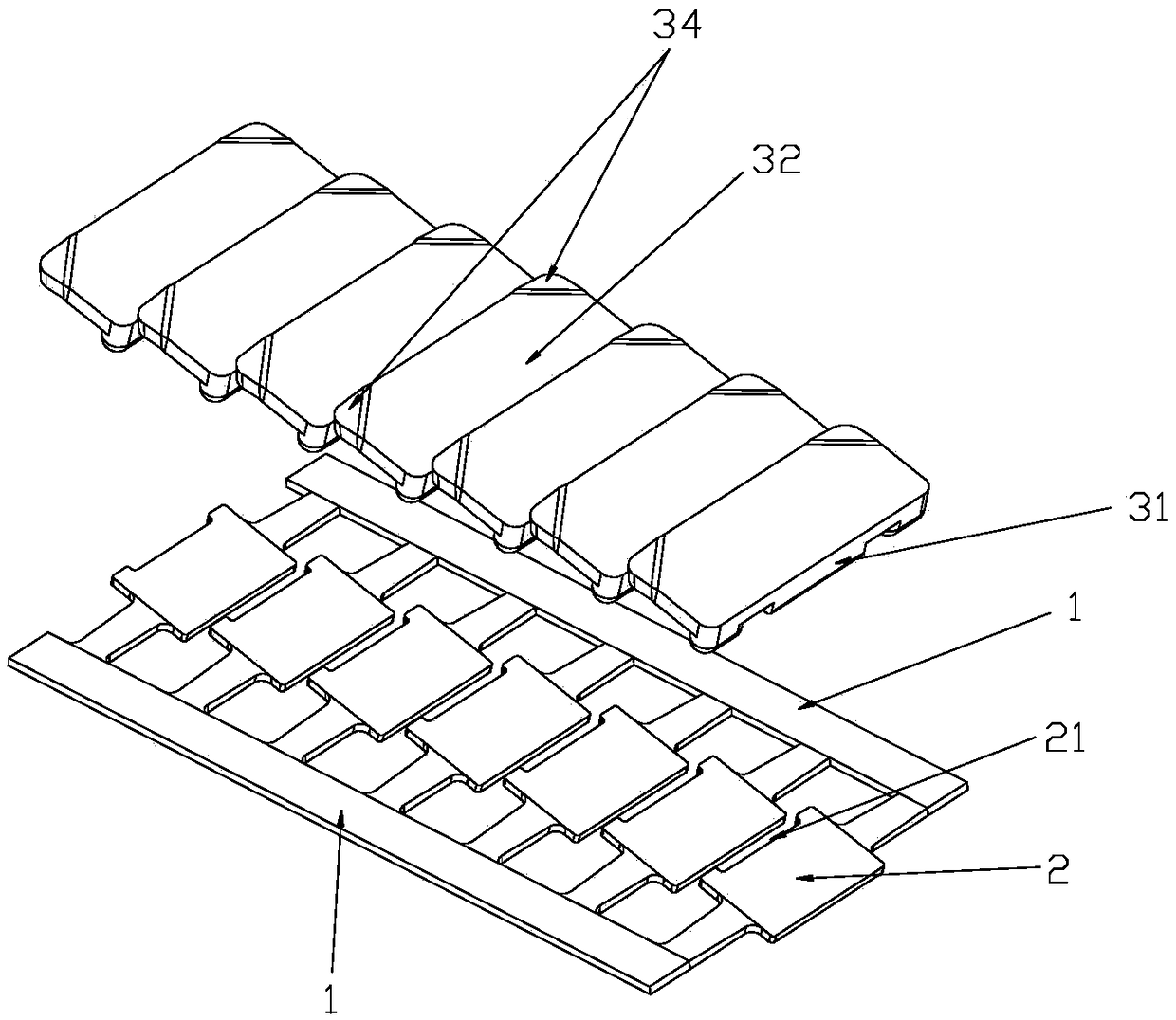

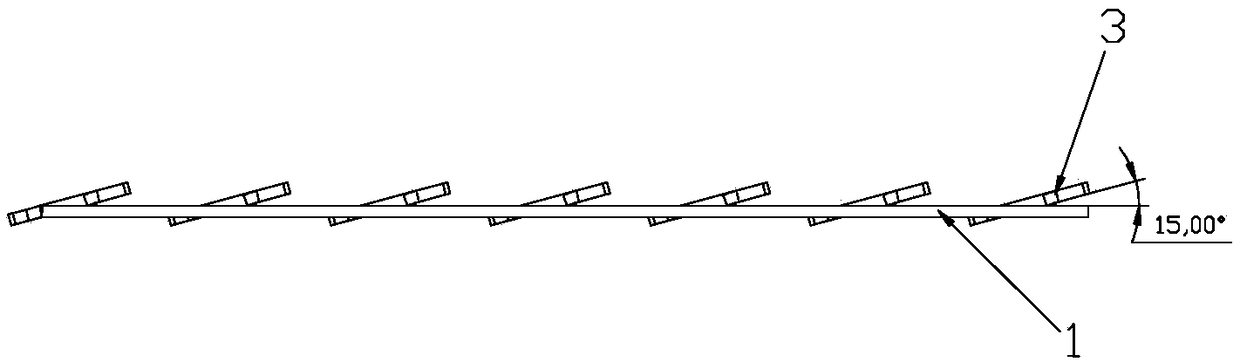

[0021] Such as Figures 1 to 2 As shown, a multi-point contact finger includes a bracket 1 , several concave blades 2 and strap blades 3 corresponding to the number of concave blades 2 . A number of concave blades 2 are fixed on the bracket 1 at intervals. The concave blades 2 are provided with positioning grooves 21. The strap blades 3 are provided with positioning blocks 31. The strap blades 3 cooperate with the positioning blocks 31 and the positioning grooves 21. It is set on the concave blade 2. The bracket 1 is made of steel, the concave blade 2 is made of steel, and the strap blade 3 is made of red copper. The steel bracket 1 and the concave blade 2 provide elasticity and struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com