High-energy-density lithium ion battery

A lithium-ion battery and compaction density technology, which is applied in the field of lithium batteries, can solve problems that affect battery charging and discharging, difficult ion transmission, and powder-off of pole pieces, so as to improve battery performance, improve coating quality, and prevent powder-dropping and brittle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

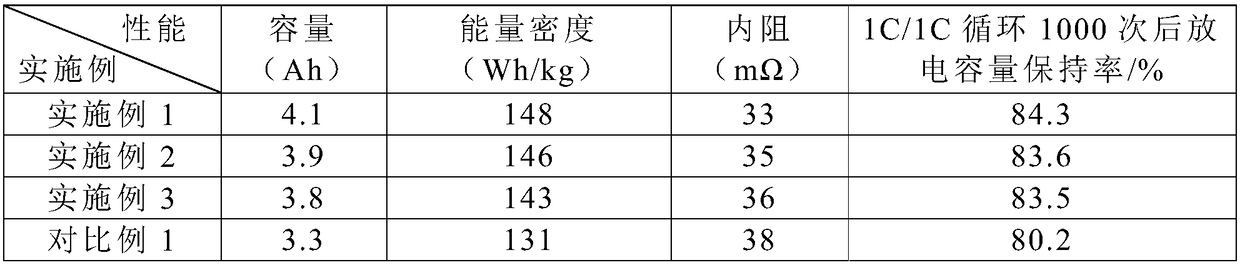

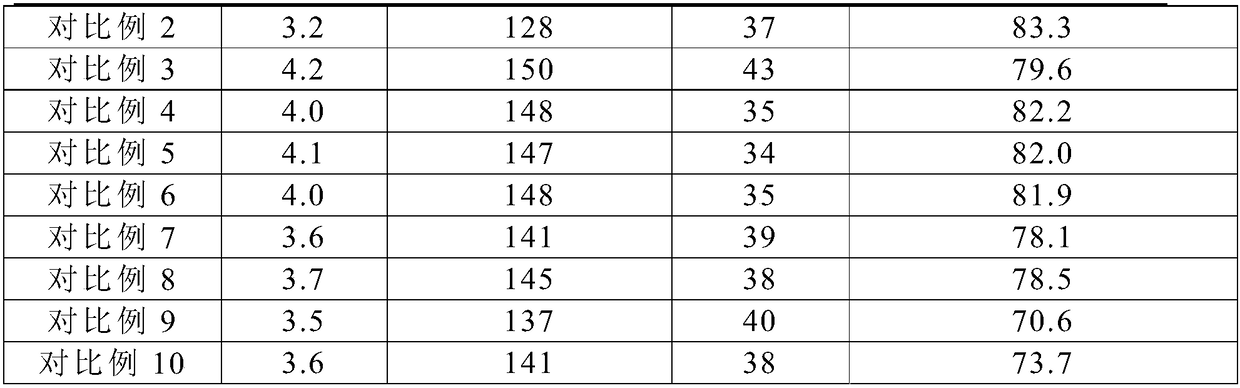

Examples

Embodiment 1

[0037] The high energy density lithium ion battery in this embodiment includes a positive pole piece, a negative pole piece, and a diaphragm.

[0038] The positive electrode sheet is coated with a positive electrode active material, and the positive electrode active material includes the following components in mass percentage: 3% of polyvinylidene fluoride, 1% of conductive carbon black, 96% of lithium iron phosphate, and the particle size of lithium iron phosphate is D 50 It is 9-10μm, and the compaction density of the positive pole piece is its ultimate compaction density of 2.45g / cm 3 , surface density is 370g / m 2 .

[0039]The negative pole sheet is coated with negative active material, and the negative active material comprises the following mass percentage components: CMC1.6%, conductive carbon black 1.5%, graphite 94.9%, styrene-butadiene emulsion 2%, and the compacted density of the negative pole piece is 1.46g / cm 3 , with a thickness of 120 μm.

[0040] Wherein, ...

Embodiment 2

[0046] The high energy density lithium ion battery in this embodiment includes a positive pole piece, a negative pole piece, and a diaphragm.

[0047] The positive electrode sheet is coated with a positive active material, and the positive active material includes the following components in mass percentage: 2.7% polyvinylidene fluoride, 0.8% conductive carbon black, 96.5% lithium iron phosphate, the particle size of lithium iron phosphate is D 50 It is 8-9μm, and the compaction density of the positive pole piece is its ultimate compaction density of 2.55g / cm 3 , surface density is 380g / m 2 .

[0048] Negative pole sheet is coated with negative pole active material, and negative pole active material comprises the component of following mass percent: CMC1.5%, conductive carbon black 1.4%, graphite 95.2%, styrene-butadiene emulsion 1.9%, the compaction density of negative pole pole piece is 1.5g / cm 3 , with a thickness of 115 μm.

[0049] Wherein, the styrene content of the ...

Embodiment 3

[0055] The high energy density lithium ion battery in this embodiment includes a positive pole piece, a negative pole piece, and a diaphragm.

[0056] The positive electrode sheet is coated with a positive electrode active material, and the positive electrode active material includes the following components in mass percentage: 3.2% of polyvinylidene fluoride, 1.3% of conductive carbon black, 96.5% of lithium iron phosphate, and the particle size of lithium iron phosphate is D 50 It is 10-11μm, and the compaction density of the positive pole piece is its ultimate compaction density of 2.4g / cm 3 , surface density is 360g / m 2 .

[0057] Negative pole sheet is coated with negative pole active material, and negative pole active material comprises the component of following mass percentage: CMC1.7%, conductive carbon black 1.6%, graphite 94.6%, styrene-butadiene emulsion 2.1%, the compaction density of negative pole pole piece is 1.4g / cm 3 , with a thickness of 125 μm.

[0058]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com