Electro-hydraulic mix-drive vertical lifting device

A hybrid drive, hydroelectric technology, applied in fluid pressure actuation devices, lifting devices, fluid pressure actuation system components, etc., can solve the problems of shock, vibration, high installation accuracy, and low system power-to-weight ratio. Achieve the effect of low cost, convenient operation and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

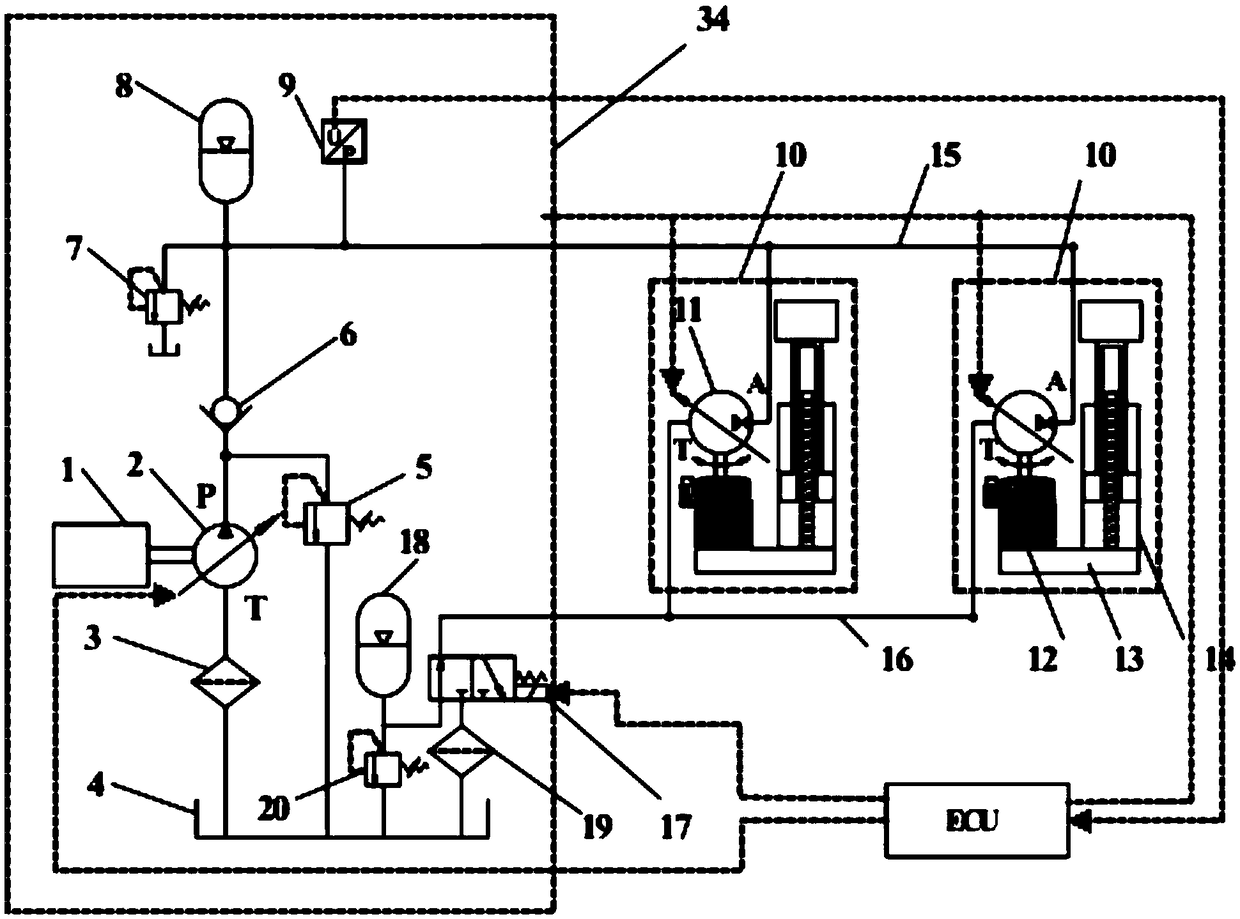

Embodiment 1

[0043] like Figure 2-3 As shown, a lifting device driven by a hydraulic-electric hybrid includes a power source, a main hydraulic pump, a filter I, a filter II, an oil tank, an overflow valve I, a check valve I, and an overflow valve II Valve, No. I hydraulic accumulator, pressure sensor, No. I driving cylinder, No. II driving cylinder, reversing valve, No. II hydraulic accumulator, No. III overflow valve, high-pressure pipeline and low-pressure pipeline;

[0044] The power source is mechanically connected with the main hydraulic pump, the oil suction port of the main hydraulic pump communicates with the oil tank through the first filter, and the oil outlet of the main hydraulic pump is connected with the oil inlet of the first one-way valve and the inlet of the first relief valve at the same time. The oil port is connected, the oil outlet of the first relief valve is connected with the oil tank, and the oil outlet of the first one-way valve is connected with the oil inlet of...

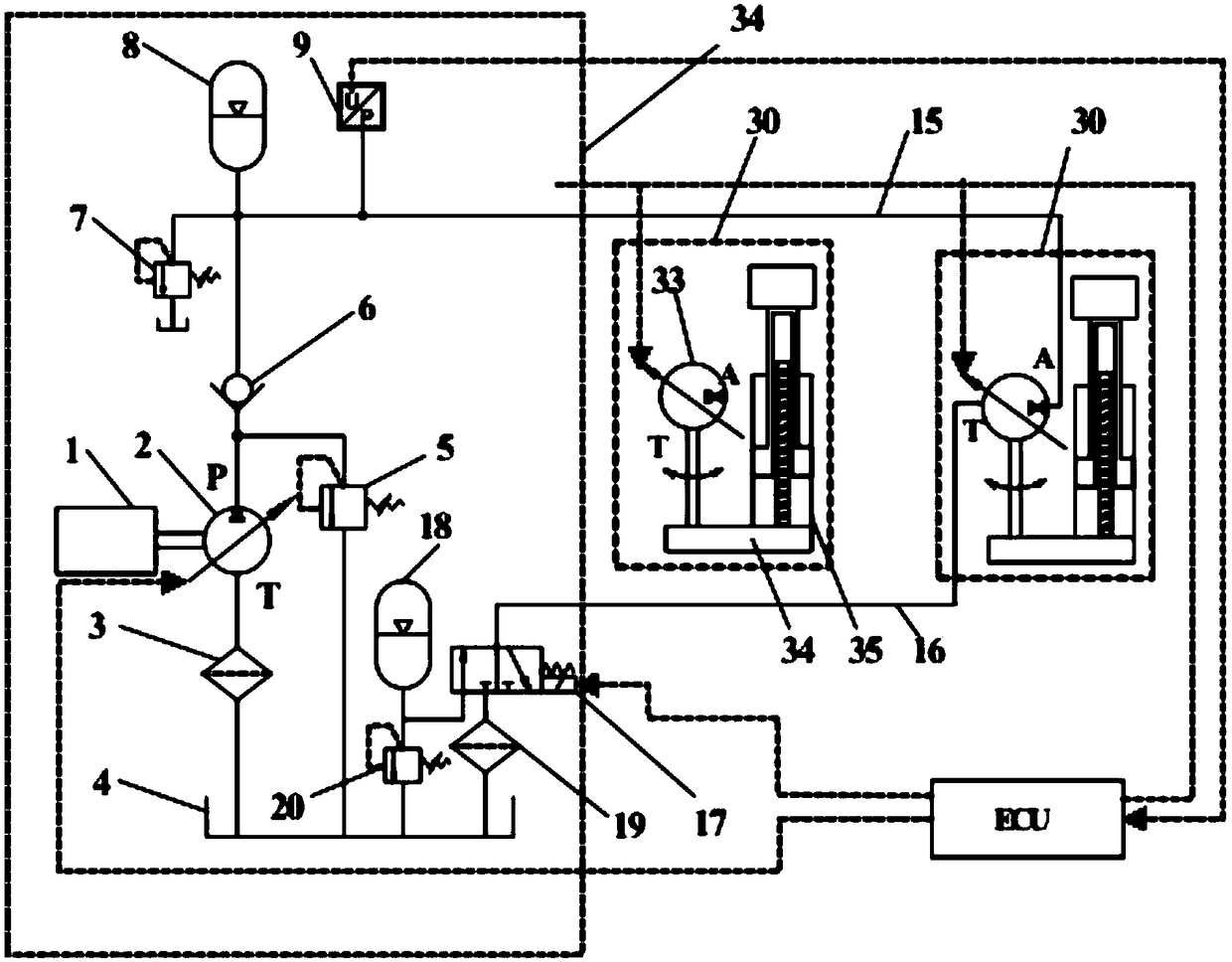

Embodiment 2

[0049] like Figure 4-5 As shown, a lifting device driven by a hydraulic-electric hybrid includes a power source, a main hydraulic pump, a filter I, a filter II, an oil tank, an overflow valve I, a check valve I, and an overflow valve II Valve, No. I hydraulic accumulator, pressure sensor, No. I driving cylinder, No. II driving cylinder, reversing valve, No. II hydraulic accumulator, No. III overflow valve, high-pressure pipeline and low-pressure pipeline;

[0050] The power source is mechanically connected with the main hydraulic pump, the oil suction port of the main hydraulic pump communicates with the oil tank through the first filter, and the oil outlet of the main hydraulic pump is connected with the oil inlet of the first one-way valve and the inlet of the first relief valve at the same time. The oil port is connected, the oil outlet of the first relief valve is connected with the oil tank, and the oil outlet of the first one-way valve is connected with the oil inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com