Precast assembled composite thermal insulation external wall and construction method thereof

A composite thermal insulation and prefabricated assembly technology, which is applied in thermal insulation, walls, building components, etc., can solve problems such as difficulty in ensuring schedule requirements, construction quality, and poor sound insulation, so as to achieve reliable wall quality, shorten construction period, and improve The effect of thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

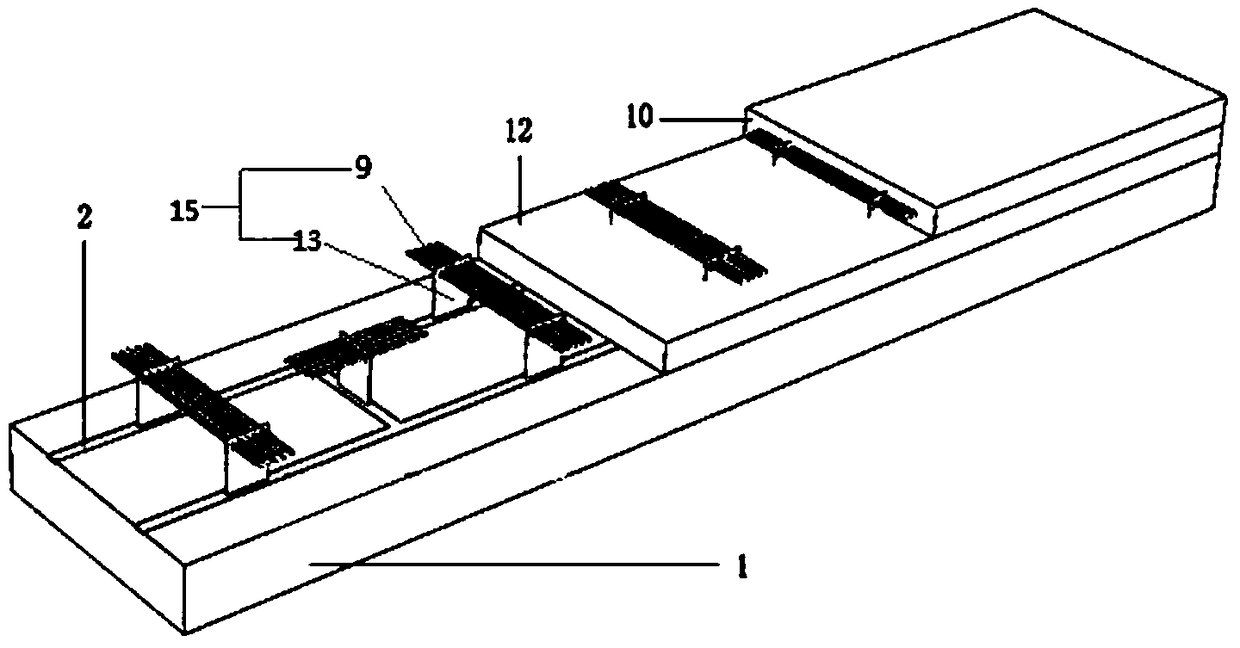

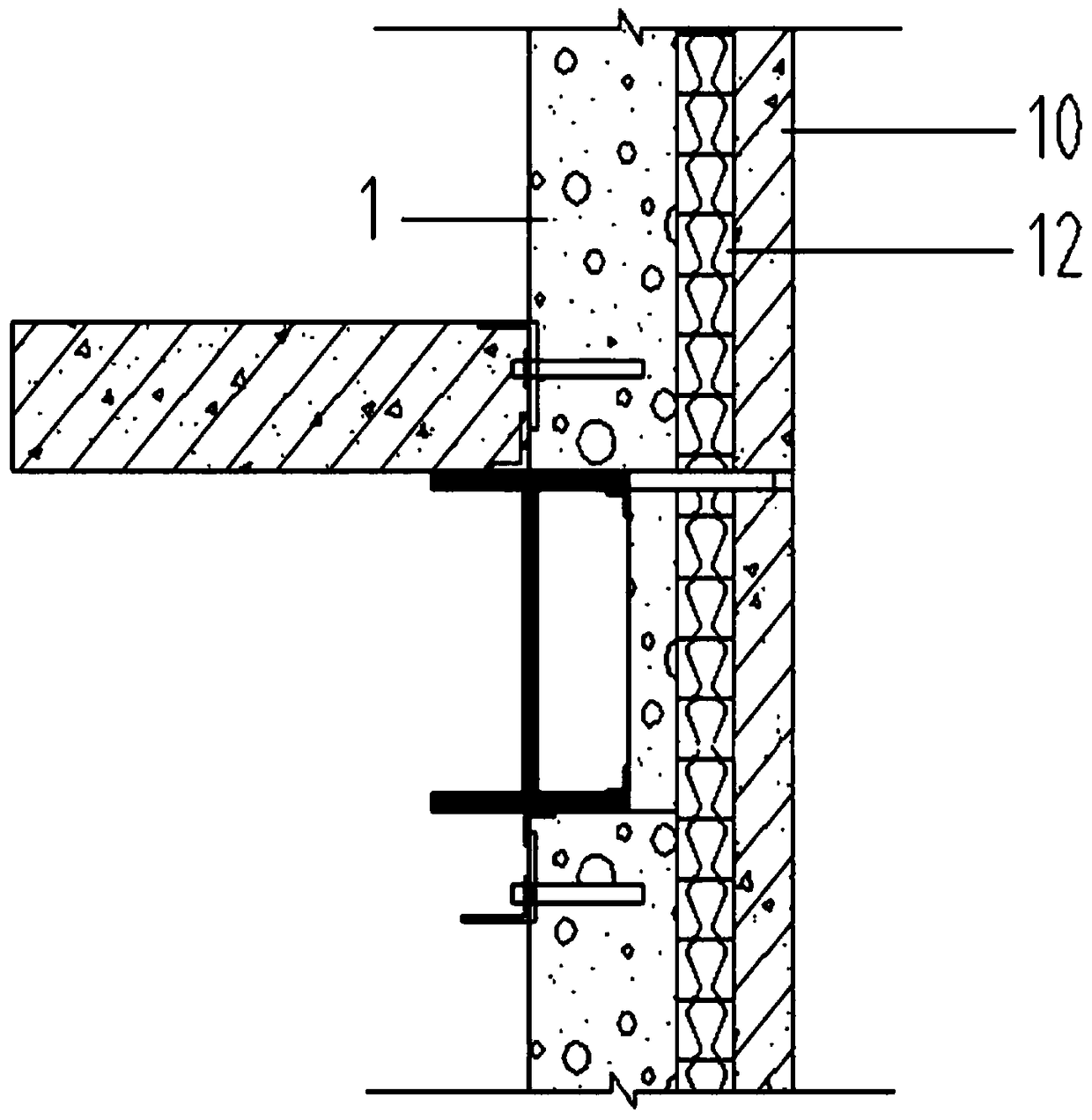

[0043] refer to Figure 1-8 , a prefabricated composite thermal insulation exterior wall, comprising an outer panel 10, a new connector 15, and an inner panel 1, the outer panel 10 and the inner panel 1 are fixedly connected by a new connector to form a thermal insulation layer 12, and the thermal insulation The layer is used to place the organic thermal insulation material, and in the present embodiment, the organic thermal insulation material is a rigid polyurethane thermal insulation board;

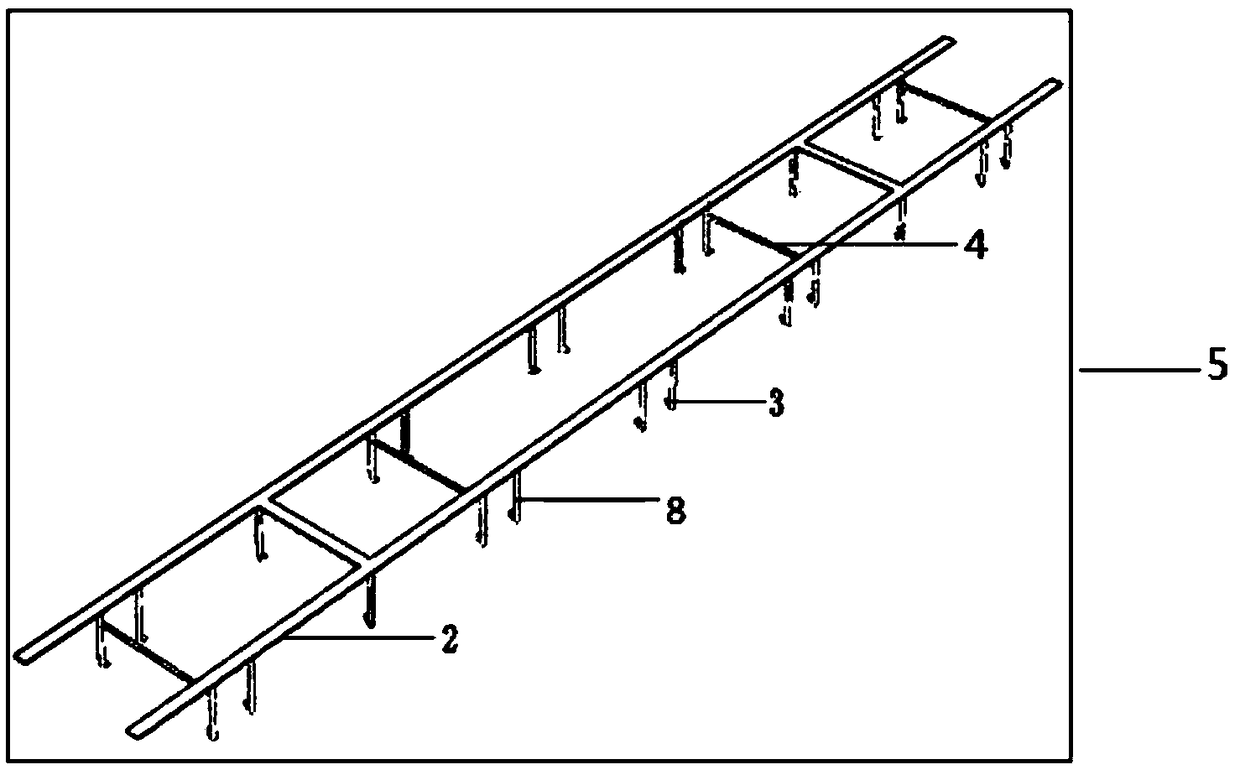

[0044]The inner panel 1 is an autoclaved aerated concrete slab, and the autoclaved aerated concrete slab includes a fixing member 5, an upper steel mesh sheet, and a lower layer steel mesh sheet, and the upper layer steel mesh sheet and the lower layer steel mesh sheet pass through the fixing piece 5 connected, poured in lightweight aggregate concrete, and autoclaved at high temperature to form an autoclaved aerated concrete slab, which not only has a certain thermal insulation perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com