ZIF-8/polyvinylidene fluoride composite nanofiber membrane and preparation method and application thereof

A composite nanofiber and polyvinylidene fluoride technology, which is applied in fiber types, fiber treatment, textiles and papermaking, etc., can solve the problems of harsh process conditions, low loading rate, zeolite imidazolate skeleton, particle agglomeration, etc., and achieve simple process Practical, overcome the serious phenomenon of crystal agglomeration, and have good membrane regeneration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

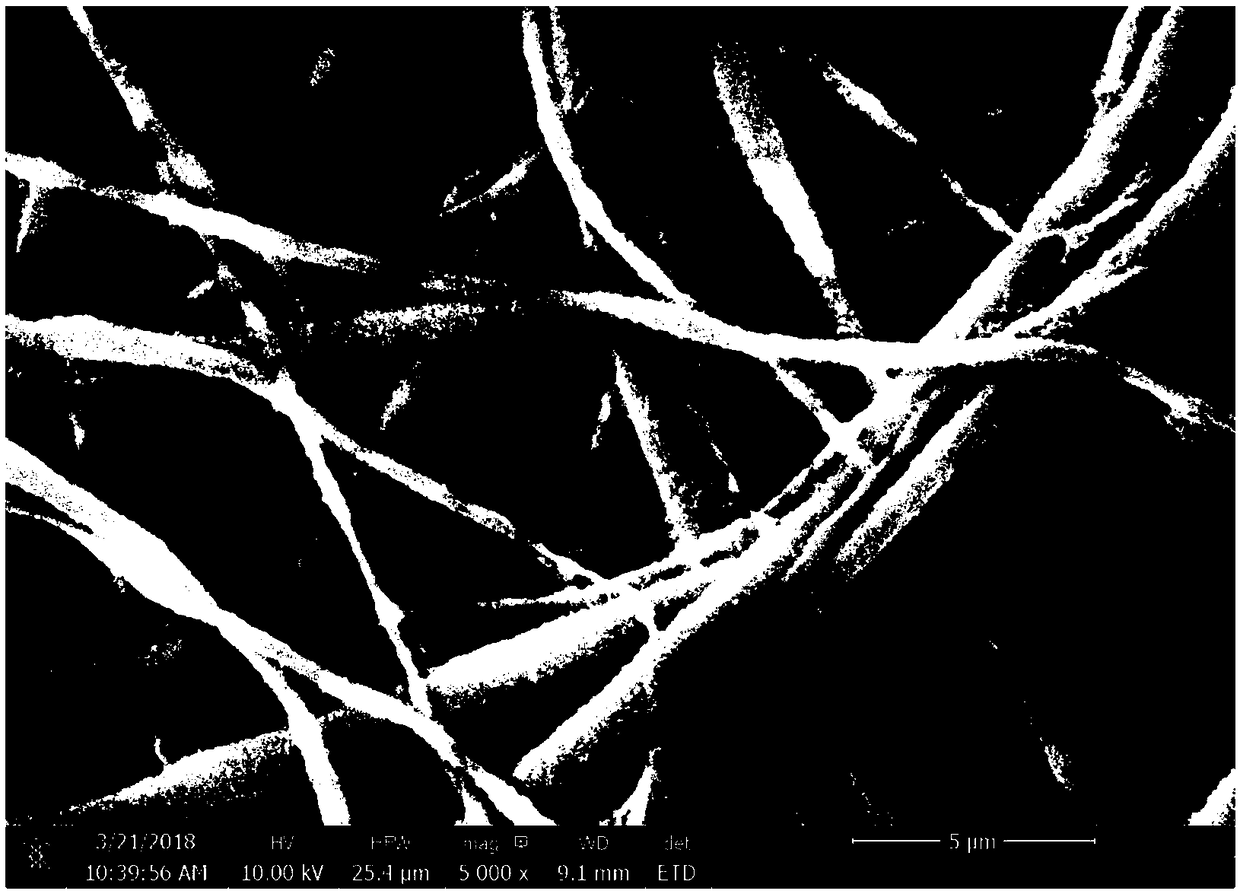

Embodiment 1

[0033] (1) Measure 3.5mL dimethylacetamide and 5.9mL acetone, mix and stir for 0.5h, then add 0.54g of 2-methylimidazole, stir for 1h until dissolved; then add 0.8g of polyvinylidene fluoride, 50℃ Under heating and stirring for 10h, a spinning solution was obtained;

[0034] (2) The spinning solution prepared by step (1) is filled in a syringe with a No. 18 flat needle for spinning, the injection speed is 0.03mm / min, the voltage is 12.5kV, the receiving distance is 15cm, and the relative humidity is 20%. , the relative temperature is 24°C, and the receiving device is a roller collector to obtain a polyvinylidene fluoride electrospun film;

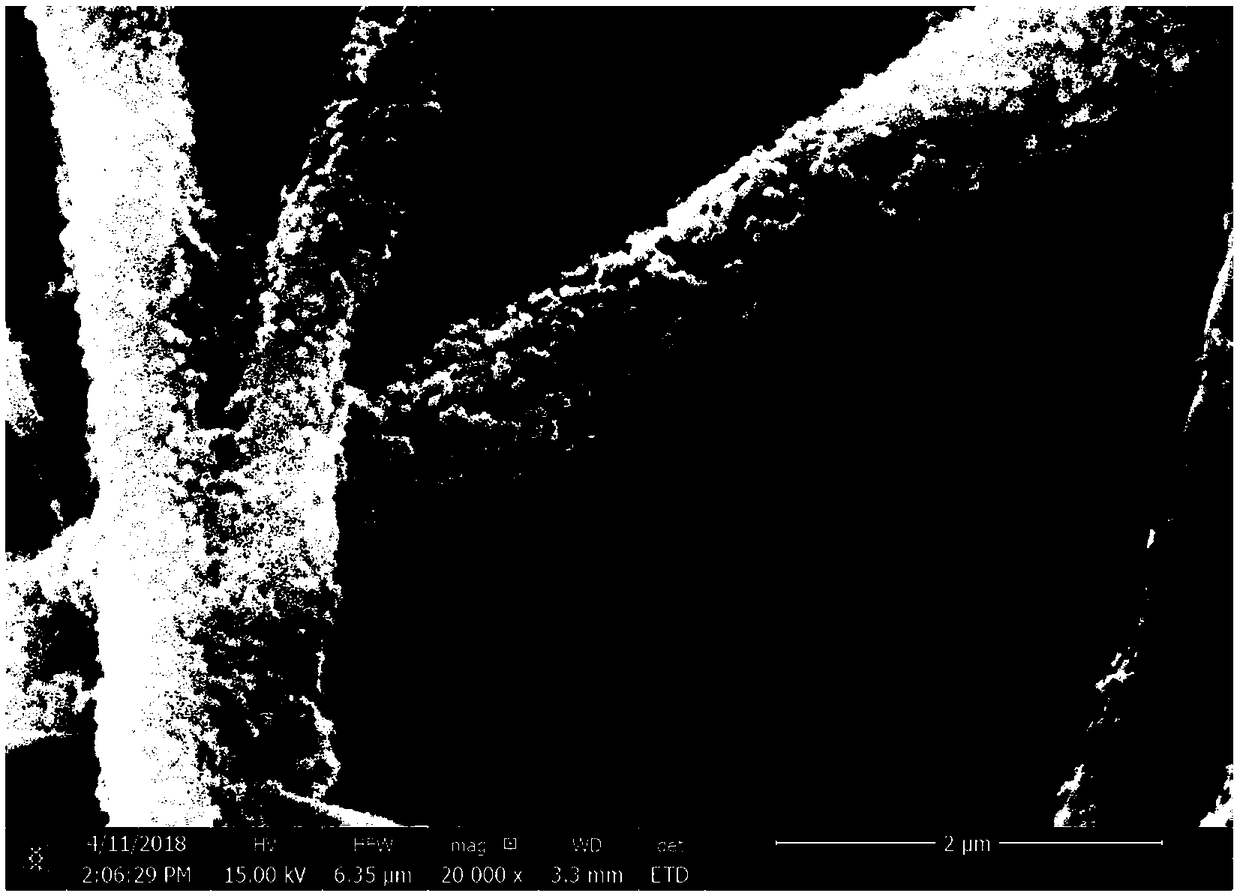

[0035] (3) Weigh 4.1g of zinc nitrate hexahydrate and dissolve it in 40mL of methanol solution, put 2g of the polyvinylidene fluoride electrospun membrane prepared by step (2), heat at 40°C for 5h, and wash three times with methanol to obtain Composite seed film of -8;

[0036] (4) Weigh 0.3g of zinc nitrate hexahydrate and 0.08g of 2-met...

Embodiment 2

[0039] (1) Measure 4.5mL dimethylacetamide and 6.2mL acetone, mix and stir for 1h, then add 0.725g of 2-methylimidazole, stir for 2h until dissolved; then add 1.45g of polyvinylidene fluoride, heat at 60°C Stir for 8h to obtain a spinning solution;

[0040] (2) The spinning solution prepared by step (1) is filled in a syringe with a No. 18 flat needle for spinning, the injection speed is 0.05mm / min, the voltage is 14.5kV, the receiving distance is 20cm, and the relative humidity is 22%. , the relative temperature is 25°C, and the receiving device is a drum collector to obtain a polyvinylidene fluoride electrospun film;

[0041] (3) Weigh 3.9g of zinc nitrate hexahydrate and dissolve it in 40mL of methanol solution, put 2g of the electrospun membrane prepared in step (2), heat at 50°C for 3h, and then wash three times with methanol to obtain a composite crystal with ZIF-8 Seed film;

[0042](4) Weigh 1.2g of zinc nitrate hexahydrate and 0.16g of 2-methylimidazole, dissolve th...

Embodiment 3

[0045] (1) Measure 4.1mL dimethylacetamide and 5.2mL acetone, mix and stir for 2h, then add 0.6g of 2-methylimidazole, stir for 3h until dissolved; then add 2.0g of polyvinylidene fluoride, heat at 70°C Stir for 5h to obtain a spinning solution;

[0046] (2) the spinning solution prepared by step (1) is filled in the syringe of No. 18 flat needles for spinning, the injection speed is 0.065mm / min, the voltage is 18kV, the receiving distance is 15cm, and the relative humidity is 29%. The relative temperature is 27°C, and the receiving device is a drum collector to obtain a polyvinylidene fluoride electrospun film;

[0047] (3) Weigh 2.5g of zinc nitrate hexahydrate and dissolve it in 40mL of methanol solution, put 2g of polyvinylidene fluoride electrospun membrane prepared by step (2), heat at 60°C for 2h, and then wash three times with methanol to obtain Composite seed film of -8;

[0048] (4) Weigh 1.6g of zinc nitrate hexahydrate and 0.12g of 2-methylimidazole, dissolve the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com