Method for mixing deer feces and corn straw to prepare organic fertilizer

A corn stalk and organic fertilizer technology, which is applied in the preparation of organic fertilizers, organic fertilizers, organic fertilizer equipment, etc., can solve the problems of difficult popularization and application, complicated methods, and high costs, and achieve strong operability, simple methods, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0014] Example 1: Preparation of organic fertilizer

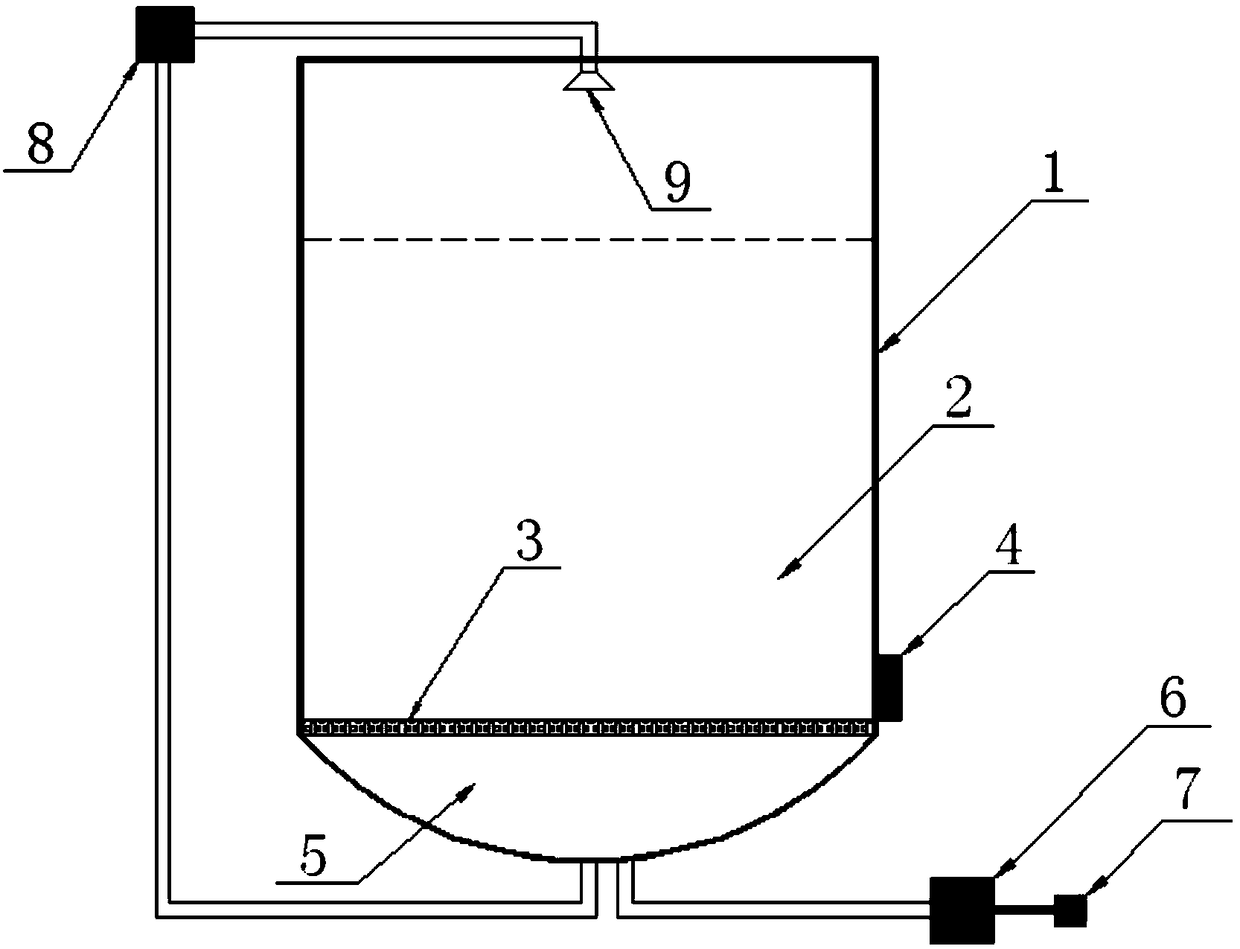

[0015] Such as figure 1 As shown, the fermentation device includes a fermentation tank 1, a liquid pump 8 refill system and an air pump 6 oxygen supplement system. The fermentation tank 1 is divided into a fermentation room 2 and a liquid storage room 5 by a ventilation filter plate 3, and the bottom of the fermentation room 2 is connected to the ventilation filter. A discharge port 4 is set at the joint of the plate 3, the leachate collected in the liquid storage room 5 is refilled into the fermentation room 2 through the nozzle 9, and the air pump 6 provides air for the fermentation room 2 intermittently through the control switch 7.

[0016] The ventilation rate of the air pump 6 is 0.5 L / min, and the continuous ventilation is 10 minutes per hour; the opening rate of the ventilation filter plate 3 is 30%, and the capacity of the liquid storage room 5 is 25% of that of the fermentation room 2; After 3 min the aeration of...

example 2

[0019] Example 2: Preparation of organic fertilizer

[0020] Such as figure 1 As shown, the fermentation device was prepared, equipped with an oxygen replenishment system and a leachate refilling system at the same time, the ventilation rate of the air pump 6 was 0.9L / min, and the continuous ventilation was 18min per hour; the opening rate of the ventilation filter plate 3 was 15%, and the liquid storage room The capacity of 5 is 10% of that of fermentation room 2; 5 minutes after liquid pump 8 is drained and recharged, it starts to ventilate and supply air to the fermenter.

[0021] The mixed fermentation materials in the fermentation room 2 are deer dung and corn stalks, the initial moisture content is 70%, the initial carbon-to-nitrogen ratio is 33:1, the crushed length of straw is less than 3.5cm, and the total fermentation time is 15 days. The above fermentation time is 5 days, and the pH is controlled between 6.5 and 7.5.

[0022] The organic fertilizer is prepared by ...

example 3

[0023] Example 3: Preparation of organic fertilizer

[0024] Such as figure 1 As shown, the complete system of the fermentation device is prepared, the ventilation rate of the air pump 6 is 0.6L / min, and the continuous ventilation is 15min per hour; the opening rate of the ventilation filter plate 3 is 20%, and the capacity of the liquid storage room 5 is 20% of the fermentation room 2 ; 4 minutes after the pumping and refilling of the liquid pump 8 is completed, the fermentation tank is ventilated and supplied with air.

[0025] The mixed fermentation material in fermentation room 2 is deer manure and corn stalks, the initial water content is 60%, the initial carbon-to-nitrogen ratio is 30:1, the crushed length of straw is less than 2.5cm, and the total fermentation time is 14 days, of which 50°C and above The fermentation time is 6 days, and the pH is controlled between 6.5 and 7.5.

[0026] By adopting the method of the invention, the prepared organic fertilizer has high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com