Spatial structure and printing method suitable for continuous fiber 3D printing

A continuous fiber, 3D printing technology, applied in the field of additive manufacturing of continuous fiber reinforced resin, composite material structure design and manufacturing, can solve the problem that lattice structures cannot be 3D printed by continuous fibers, and achieve accelerated lightweight application, quality The effect of light weight and short manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

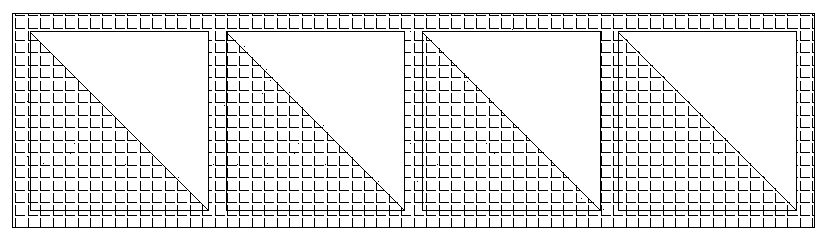

[0034] Example 1: The spatial configuration of a quadrilateral

[0035] refer to figure 1 , 2 As shown in , 3, set the working surface of the printing platform as the X-Y plane. On this plane, the rod-shaped strut is a square column with a cross-sectional side length of 1mm, and the length of the rod-shaped strut is 10mm, forming a square frame of 10mm×10mm. body. Perpendicular to the X-Y plane, the rod is a cylinder with a side length of 1mm in section, the length of the rod is 10mm, the bearing area is a right triangle with a side length of 10mm, and a thickness of 1mm.

[0036] Materials used: the rod-like struts of the network structure are continuous carbon fiber-reinforced nylon, the rod-like struts are short carbon fiber-reinforced nylon, the core material of the load-bearing area is short carbon fiber-reinforced nylon with a thickness of 0.5mm, and the reinforced skin is continuous fiber with a thickness of 0.5mm Reinforced nylon.

[0037] The components of the ab...

example 2

[0038] Example 2, Triangular Space Configuration

[0039] refer to Figure 4 , 5 , 6, 7, the printing method of the triangle space structure is as follows:

[0040] 1. Use continuous fiber reinforced PLA to print the first layer of grid structure on the printer's working plane, such as Figure 5 , wherein the rod-shaped strut is a cylinder with a side length of 2 mm and a height of 10 mm, forming an equilateral triangle;

[0041] 2. On the plane perpendicular to the grid structure, use short carbon fiber reinforced nylon to print the rod-shaped rod and the core material of the triangular bearing area. At the connection point of each rod-shaped strut of the lattice structure. The thickness of the core material in the triangular bearing area is 1mm, one of the right-angled sides is a supporting rod, and the other right-angled side is a supporting rod, and it is printed outward along the inner side of the supporting rod.

[0042] 3. Use smaller nozzles and continuous fiber-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com