A new type of 3D printing heating device

A 3D printing and heating device technology, applied in the field of 3D printing, can solve the problems of materials not suitable for dissolution, high melting point, and restrictions on 3D printing applications, and achieve the effects of high heating temperature, high processing efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below with reference to the accompanying drawings and examples. The embodiments of the present invention include but are not limited to the following examples.

[0013] In order to achieve the above object, the technical scheme adopted in the present invention is as follows:

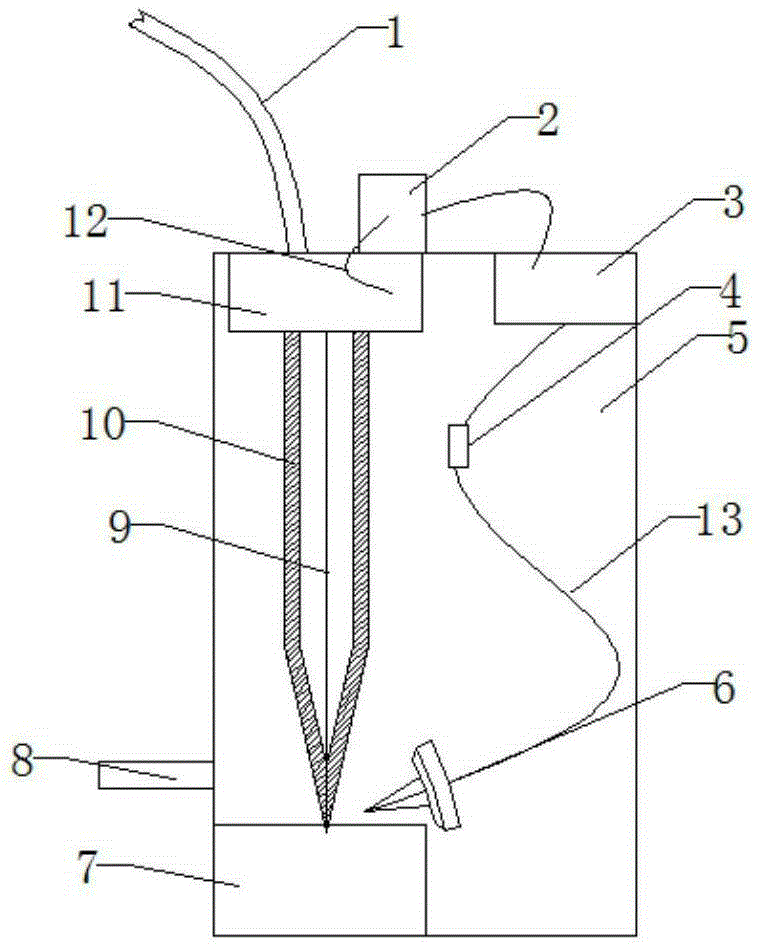

[0014] This new type of 3D printing heating device includes a silk tube 1, a temperature controller 2, a laser 3, a laser adjustment device 4, a container 5, a laser nozzle 6, a sub-processed workpiece 7 and an auxiliary gas inlet 8, a material filament 9, a nozzle 10, Heating rod 11, conducting wire 12 and conducting optical fiber 13; silk tube 1 is fixedly connected to container 5, temperature controller 2 is fixedly connected above container 5, laser 3 is connected to laser adjusting device 4 through conducting optical fiber 13, and laser adjusting device 4 is connected to laser adjusting device 4 through conducting optical fiber 13 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com