A circuit board pin cutting device

A shearing device and circuit board technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of wasting labor costs, inconvenient use, and high cost, and achieve clean and tidy protection, full automation, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

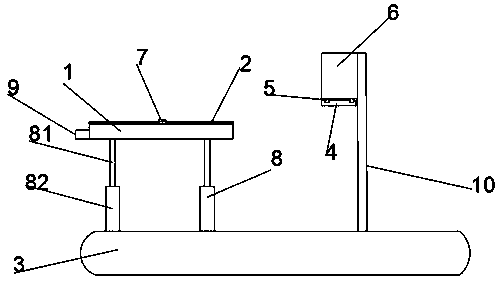

[0013] Such as figure 1 A circuit board pin cutting device is shown, the structure includes a workbench 1, a gravity sensor 2, a conveyor belt 3, a cutting blade 4, a rotating shaft 5, a support rod 10 and a motor 6, and the workbench 1 is installed above the conveyor belt 3 , the gravity sensor 2 is installed on the workbench 1, the cutting blade 4 is installed above the middle position of the conveyor belt 3, the cutting blade 4 is connected to the motor 6 through the rotating shaft 5, and the motor 6 is connected to the conveyor belt 3 through the support rod 10.

[0014] There are clamps 7 on both sides of the workbench 1 that can fix the circuit board.

[0015] There is a telescopic rod 8 at the connection between the workbench 1 and the conveyor belt 3. The telescopic rod 8 is composed of an inner rod 81 and an outer rod 82. Both the inner rod 81 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com