Grease hydrogenation reactor

A technology of oil hydrogenation and reactor, which is applied in chemical instruments and methods, refining to remove heteroatoms, chemical/physical processes, etc., can solve the problems of difficult removal and cleaning of solidified oil, reduce work efficiency, etc., and improve purity and utilization, increased pressure, high mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

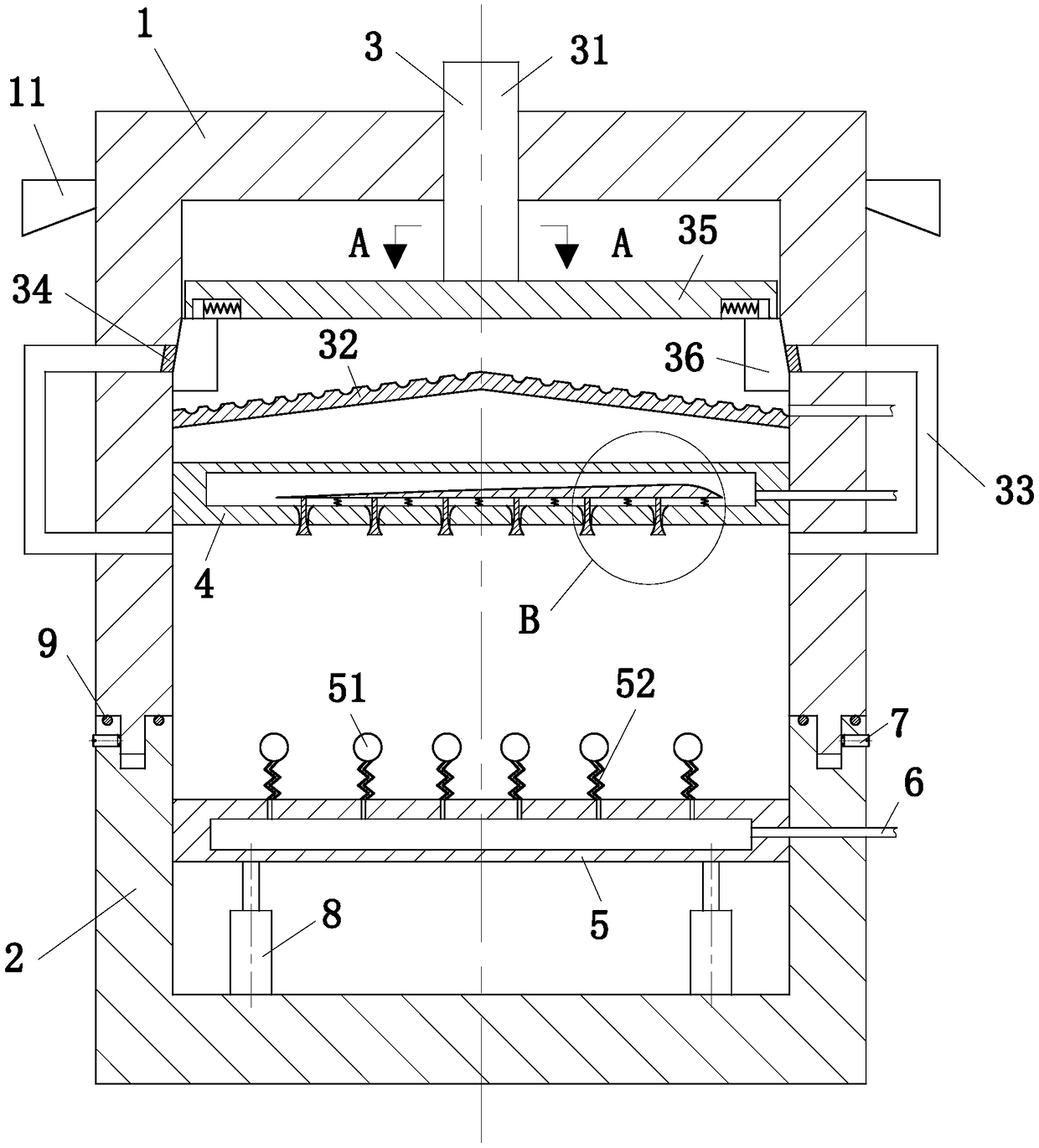

[0026] use Figure 1-Figure 4 The structure of the fats and oils hydrogenation reactor which concerns on one Embodiment of this invention is demonstrated below.

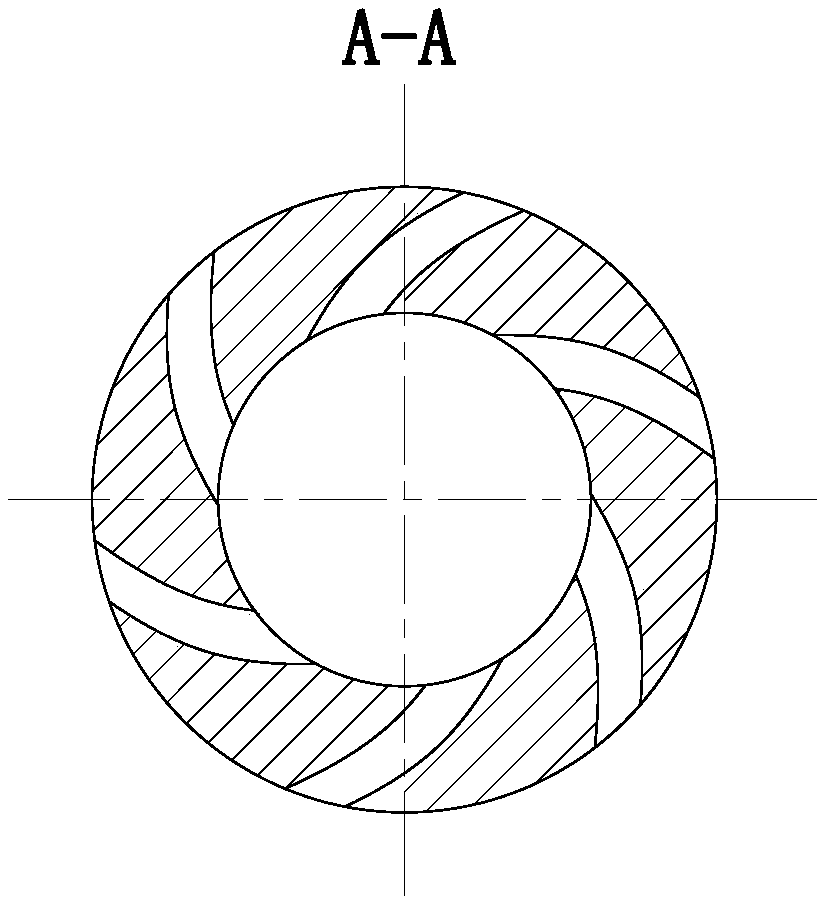

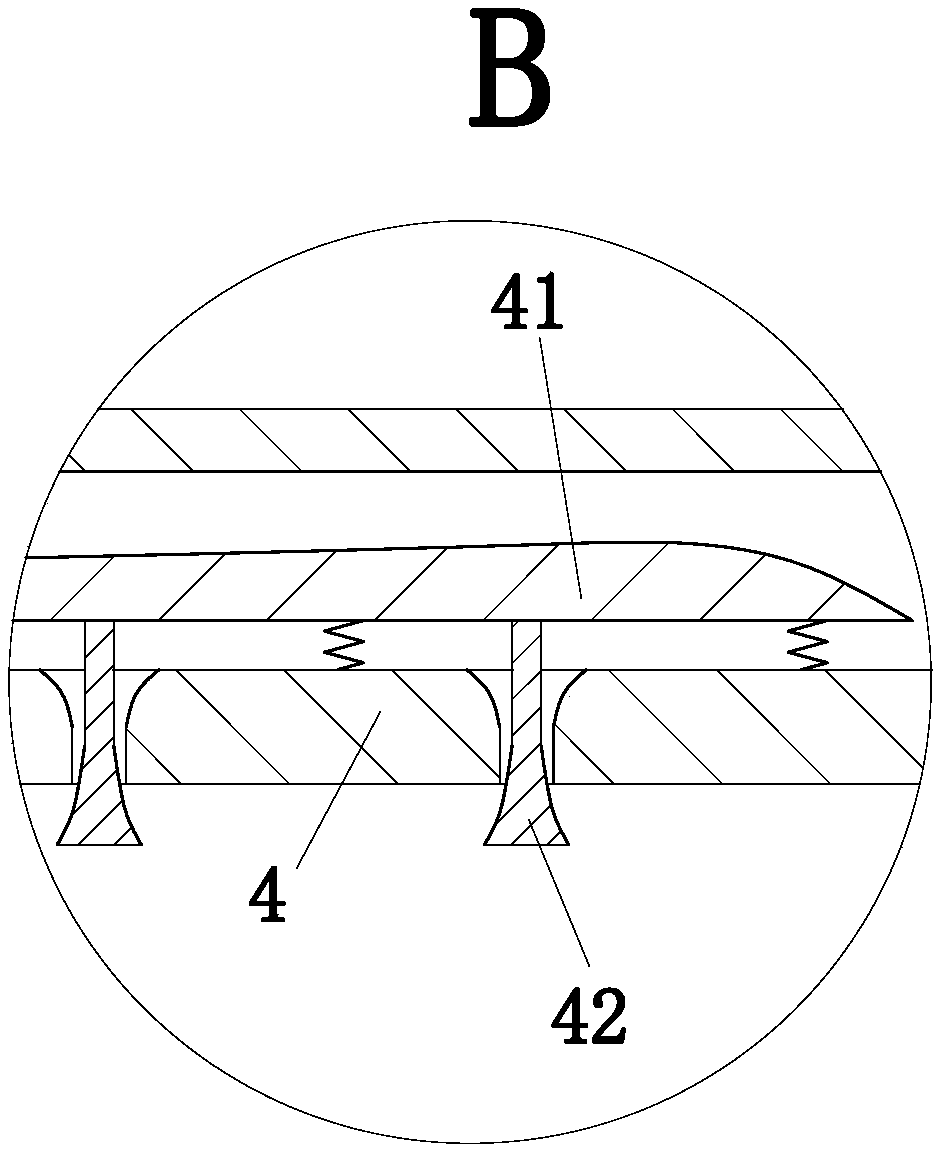

[0027] Such as figure 1 As shown, a grease hydrogenation reactor according to the present invention includes an upper box 1, a lower box 2, an oil injection unit 3, a hydrogenation plate 4 and a receiving plate 5, and the upper box 1 is open at the lower end Cylindrical box, the lower end surface of the upper box 1 is provided with a circular flange, and the outer surface of the upper box 1 is provided with lifting lugs 11, the lifting lugs 11 are used to facilitate the lifting of the upper box 1, the upper box A hydrogenation pipe 6 is arranged outside the body 1; the lower box body 2 is a cylindrical box body with an upper end opening, and an annular groove is arranged on the upper end surface of the lower box body 2, and the upper box body 1 and the lower box body 2 The connection is realized through the coopera...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap