Paclitaxel-carrying magnetic fluorescent alginate microsphere system and preparation method thereof

A technology of alginic acid and paclitaxel, applied in the field of nanomaterials, can solve the problem that there is no research or report on the magnetic fluorescent alginic acid microsphere system, and achieve the effects of mild experimental conditions and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of a magnetic fluorescent alginic acid microsphere system loaded with paclitaxel, comprising the following steps:

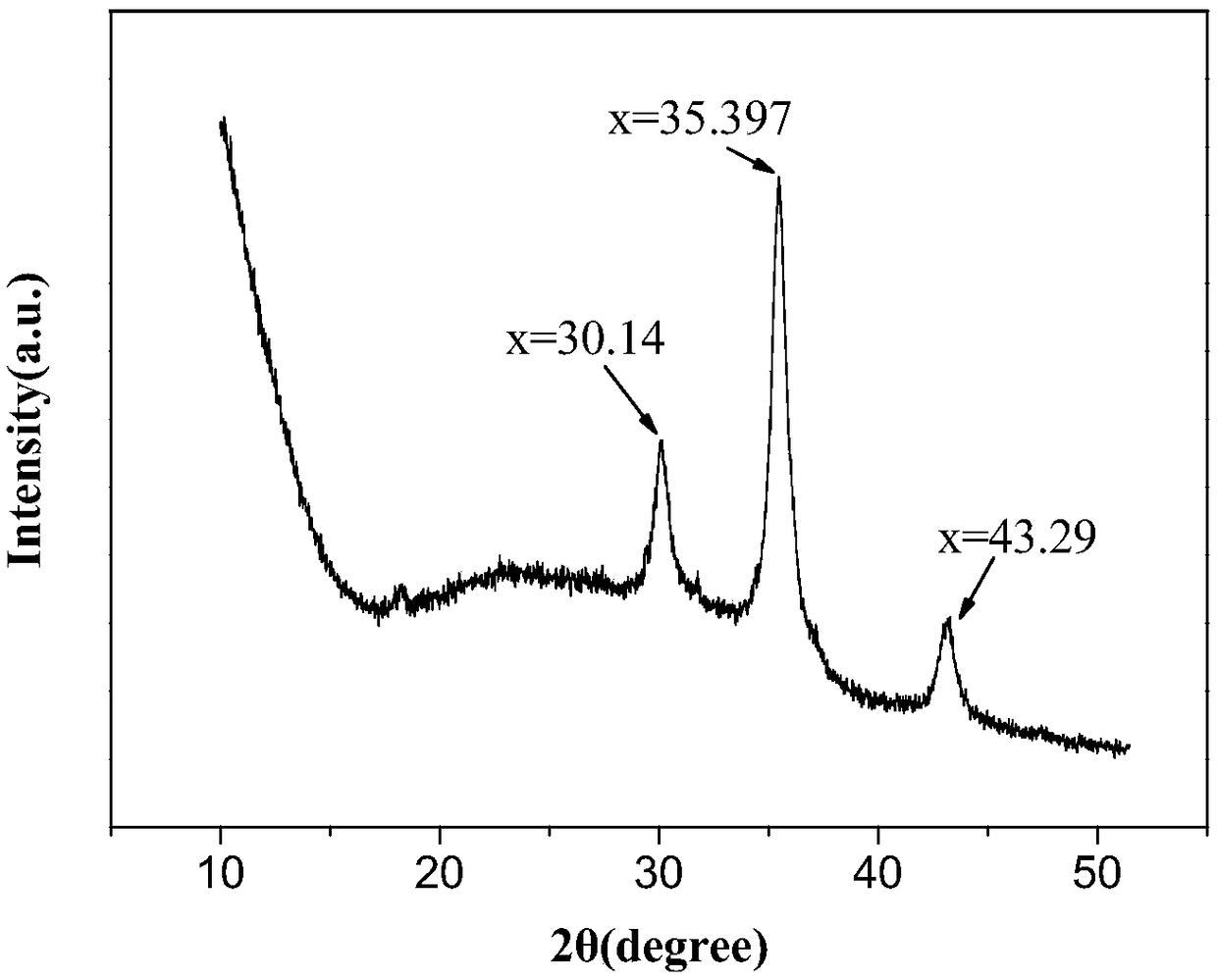

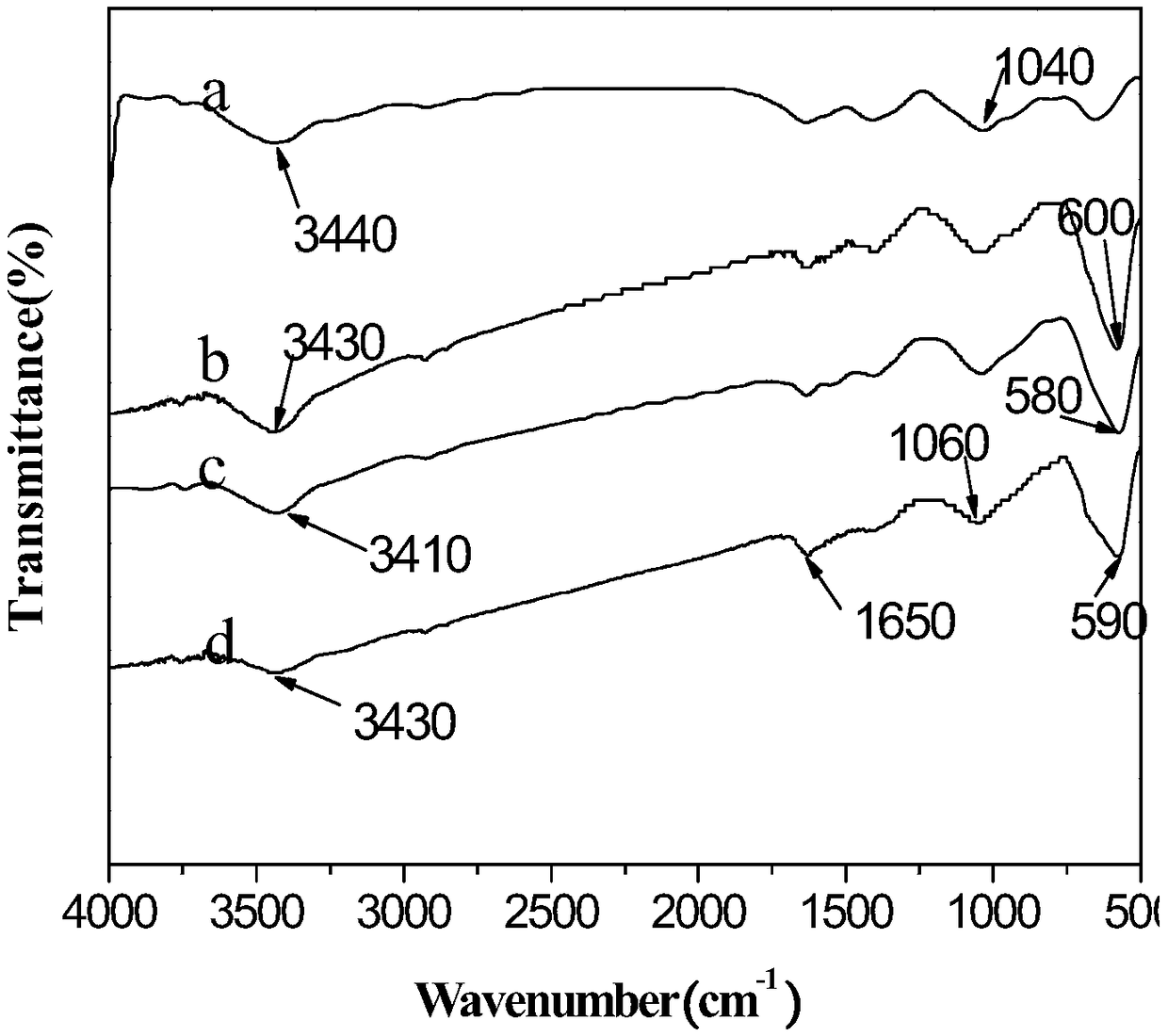

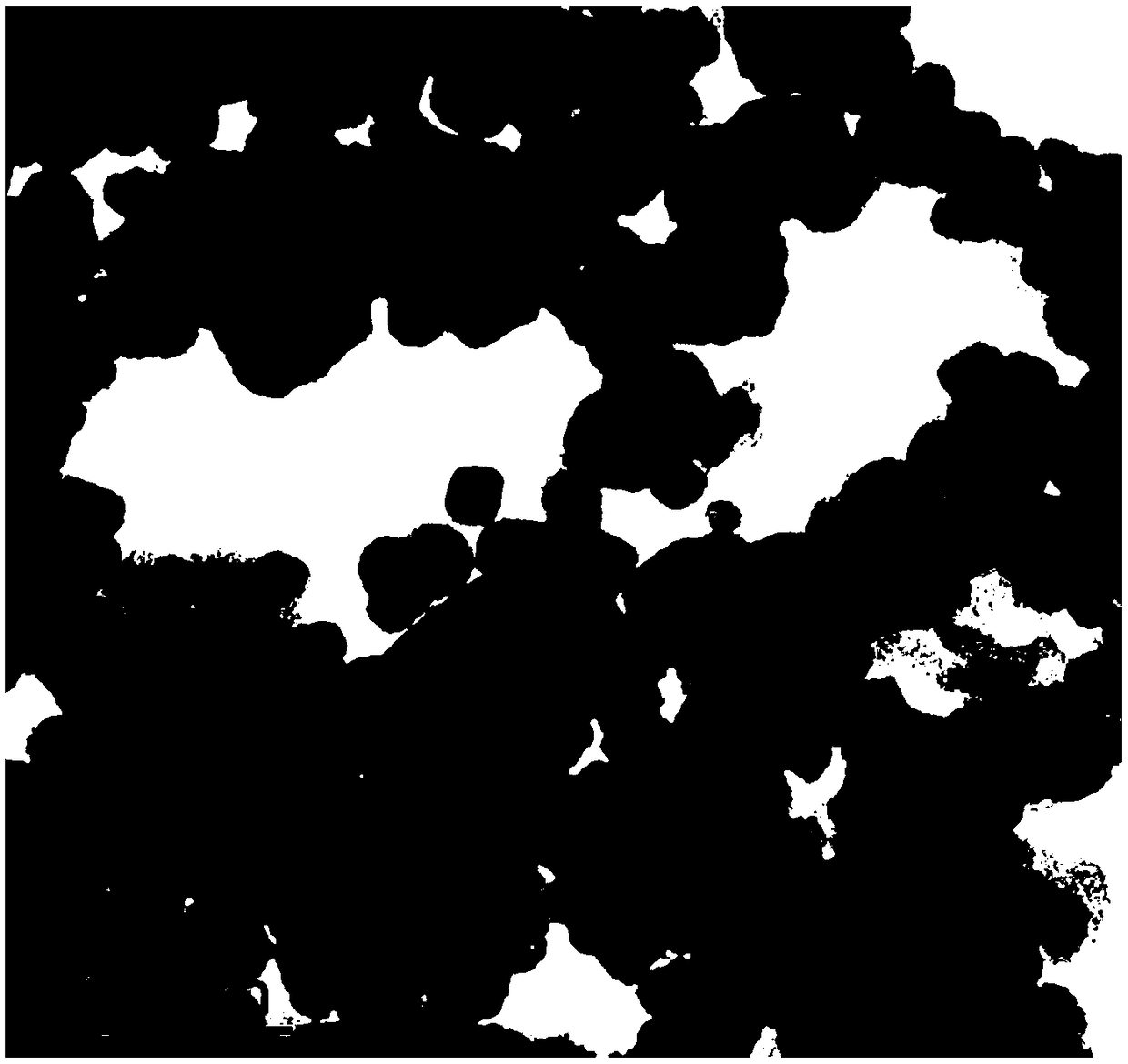

[0039] Add 1.3g ferric chloride to 72.8g (ie 70ml) 1,2-propanediol (PG), then add 0.8g urea (Urea) and 0.4g surfactant sodium dodecylbenzenesulfonate (SDBS), the The product was reacted in a muffle furnace at 210 °C for 5 h, the final product was alternately washed with distilled water and absolute ethanol, and finally dried in vacuum at 40 °C to prepare porous Fe 3 o 4 nanospheres.

[0040] 50mg Fe 3 o 4 Nano microspheres, 80g (ie 80ml) H 2 O. 1.82g (i.e. 2ml) of ammonia water to make a mixed solution, put the mixed solution in a three-necked flask for ultrasonic dispersion for 20min, then add 0.5ml of 3-aminopropyltrimethoxysilane and stir at room temperature (25°C) for 7h, the product was used Alternately washed with distilled water and absolute ethanol, and dried under vacuum at 40°C, Fe can be prepared 3 o 4 -NH 2 Nanopart...

Embodiment 2

[0044] A preparation method of a magnetic fluorescent alginic acid microsphere system loaded with paclitaxel, comprising the following steps:

[0045] Add 1.35g of ferric chloride to 74.88g (ie 72ml) of 1,2-propylene glycol (PG), then add 0.9g of urea (Urea) and 0.5g of surfactant sodium dodecylbenzenesulfonate (SDBS), the The product was reacted in a muffle furnace at 220 °C for 6 h, the final product was alternately washed with distilled water and absolute ethanol, and finally dried in vacuum at 50 °C to prepare porous Fe 3 o 4 nanospheres.

[0046] 60mg Fe 3 o 4 Nano microspheres, 90g (ie 90ml) H 2 O. 2.73g (that is, 3ml) ammonia water to make a mixed solution, put the mixed solution in a three-necked flask for ultrasonic dispersion for 30min, then add 1ml 3-aminopropyltrimethoxysilane and stir at room temperature (25°C) for 8h, and distill the product with distilled water Alternately washed with absolute ethanol and dried in vacuum at 50°C to obtain Fe 3 o 4 -NH 2 ...

Embodiment 3

[0050] A preparation method of a magnetic fluorescent alginic acid microsphere system loaded with paclitaxel, comprising the following steps:

[0051] Add 1.4g of ferric chloride to 76.96g (i.e. 74ml) of 1,2-propanediol (PG), then add 1g of urea (Urea) and 0.6g of surfactant sodium dodecylbenzenesulfonate (SDBS), and the product After reacting in a muffle furnace at 230 °C for 7 h, the final product was alternately washed with distilled water and absolute ethanol, and finally dried in vacuum at 60 °C to prepare porous Fe 3 o 4 nanospheres.

[0052] 70mg Fe 3 o 4 Nano microspheres, 100g (i.e. 100ml) H 2 0. 3.64g (i.e. 4ml) ammonia water was made into a mixed solution, the mixed solution was placed in a three-necked flask for ultrasonic dispersion for 40min, then 1.5ml of 3-aminopropyltrimethoxysilane was added and stirred at room temperature (25°C) for 9h, and the product was used Alternately washed with distilled water and absolute ethanol, and vacuum dried at 60°C, Fe ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com