Vermicelli spreader

A vermicelli and bar shaft technology, applied in the field of vermicelli processing, can solve the problems of affecting the cleanliness of vermicelli, short service life of the motor, poor economic benefits, etc., and achieve the effects of low non-stickiness, increased bearing burden, and prevention of contamination of vermicelli.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

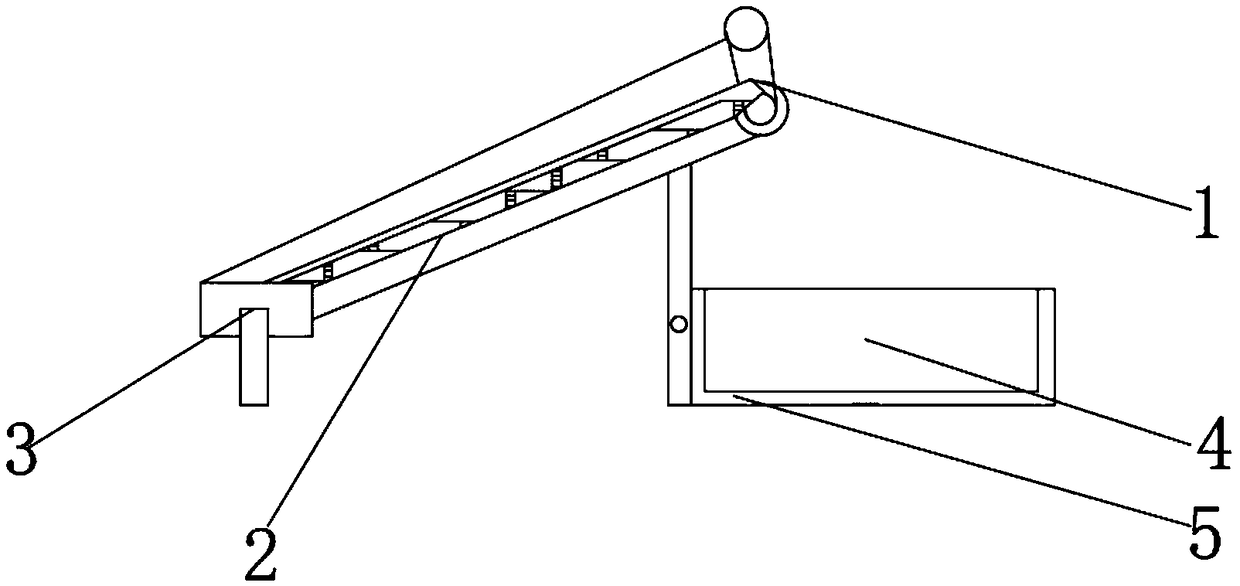

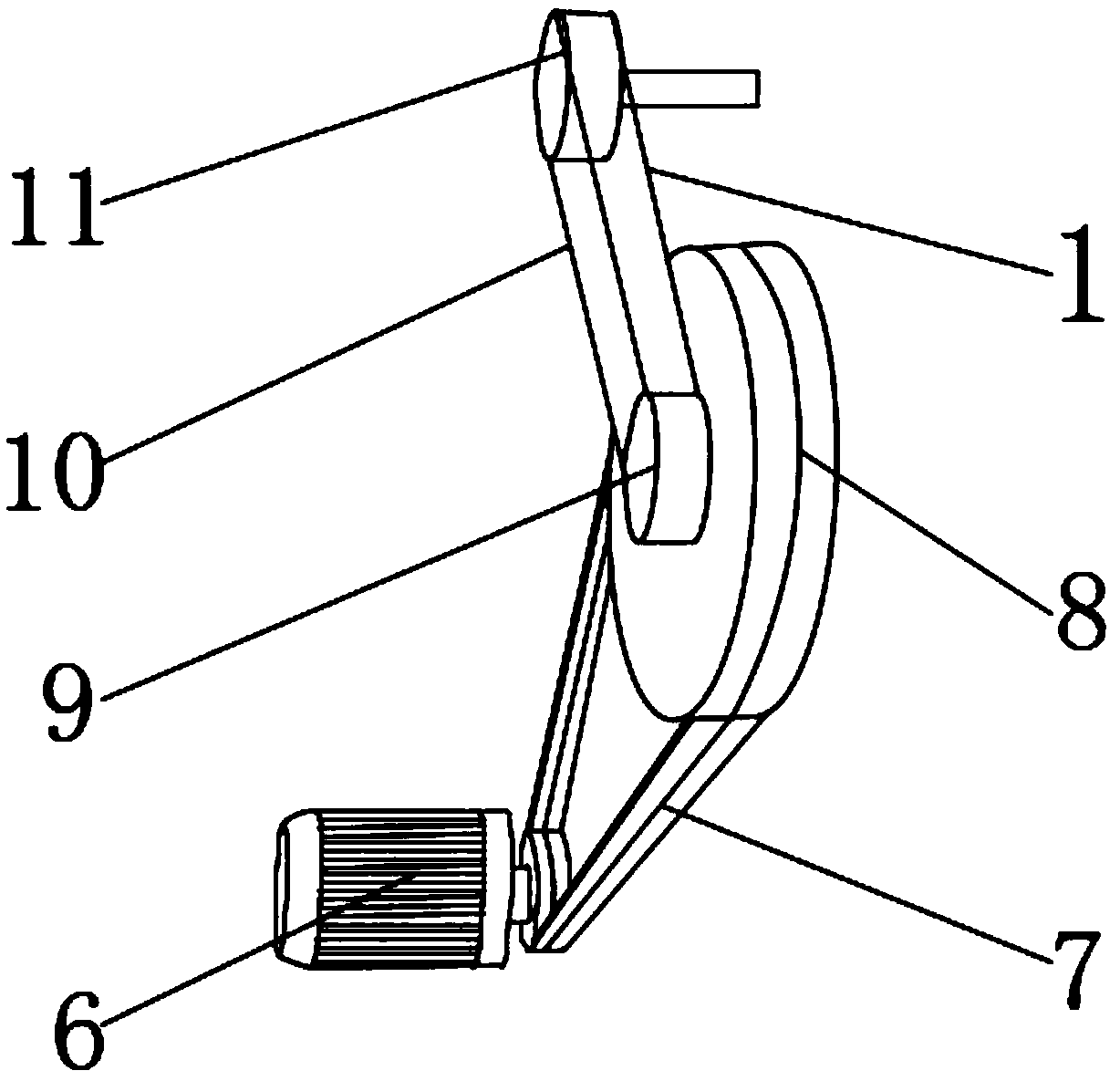

[0031] Such as Figure 1-7 As shown, a vermicelli pendulum machine includes a conveyor belt 2, a transmission assembly 1, a support frame 3 and a pendulum bar pool 4, the support frame 3 is fixedly installed on the lower end of the conveyor belt 2, and the transmission assembly 1 is fixedly installed on the upper end of the conveyor belt 2, The bottom of the transmission assembly 1 is provided with a pendulum bar pool 4, and the inner wall of the pendulum bar pool 4 is fixedly equipped with glass fiber reinforced plastics 5, through which the glass fiber reinforced plastics 5 can prevent pollution of vermicelli and ensure the cleanliness of vermicelli processing. Protective layer 26, FRP reinforced layer 25 and base material 27, FRP 5 is formed by pressing the outer protective layer 26, FRP reinforced layer 25 and substrate 27 according to the order from top to bottom, FRP 5 has excellent corrosion resistance, Keep the smoothness of the surface, and the outer protective layer ...

Embodiment 2

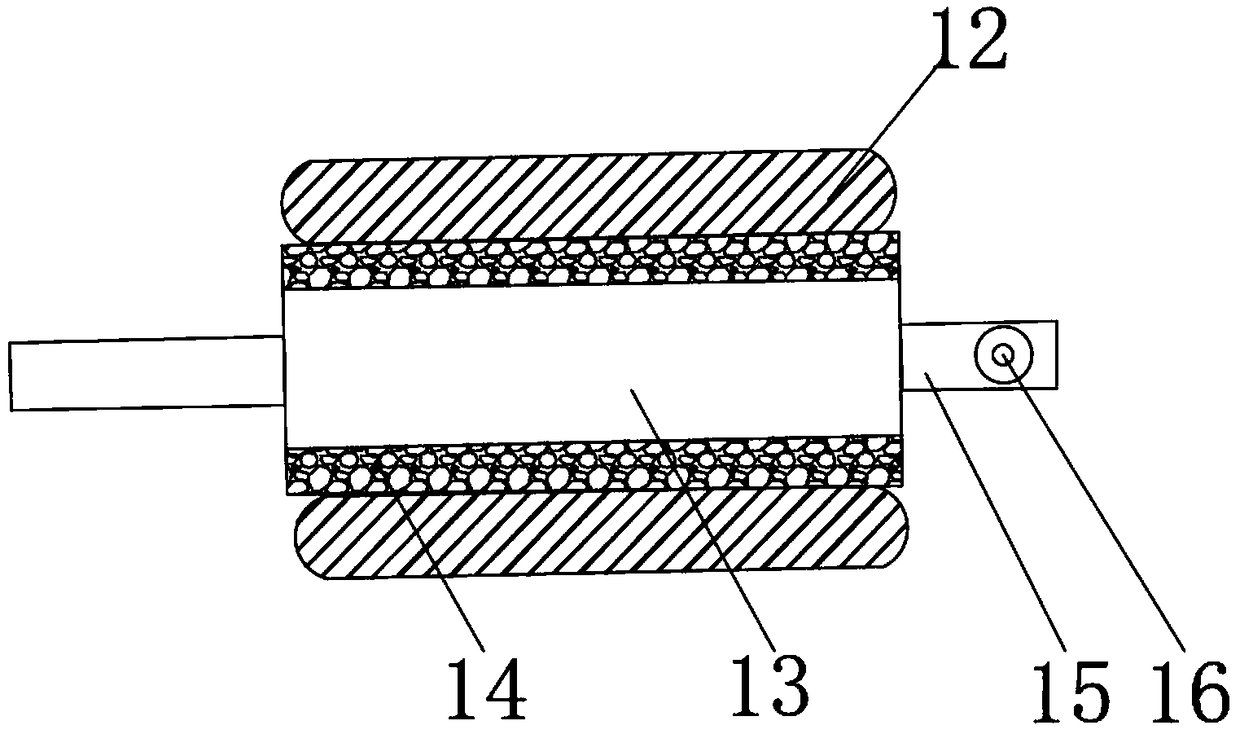

[0034] Such as Figure 1-7 As shown, a vermicelli pendulum machine, the permanent magnet motor 6 includes a rotor 13, a permanent magnet 14, a stator 12 and a motor output shaft 15, by setting the permanent magnet motor 6, the energy consumption of the motor can be reduced, and the economic benefit can be effectively improved , the rotor 13 is close to the middle position inside the permanent magnet motor 6, and both sides of the rotor 13 are fixedly equipped with permanent magnets 14, the outer surfaces of both sides of the permanent magnet 14 are provided with stators 12, and the two ends of the permanent magnet motor 6 are fixed The motor output shaft 15 is installed, after the permanent magnet motor 6 starts, the rotor 13 is consistent with the magnetic field speed of the stator 12 under the effect of the permanent magnet 14, there is no induced current in the guide bar of the rotor 13, the loss of the rotor 13 is also there, and the coil of the stator 12 is also The excit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com