Black soybean-natto fermentation food and preparation method

A technology for black bean natto and fermented food, which is applied in the directions of food ingredients, functions of food ingredients, food ingredients as taste improvers, etc. The effect of expanding the consumer group and increasing the variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

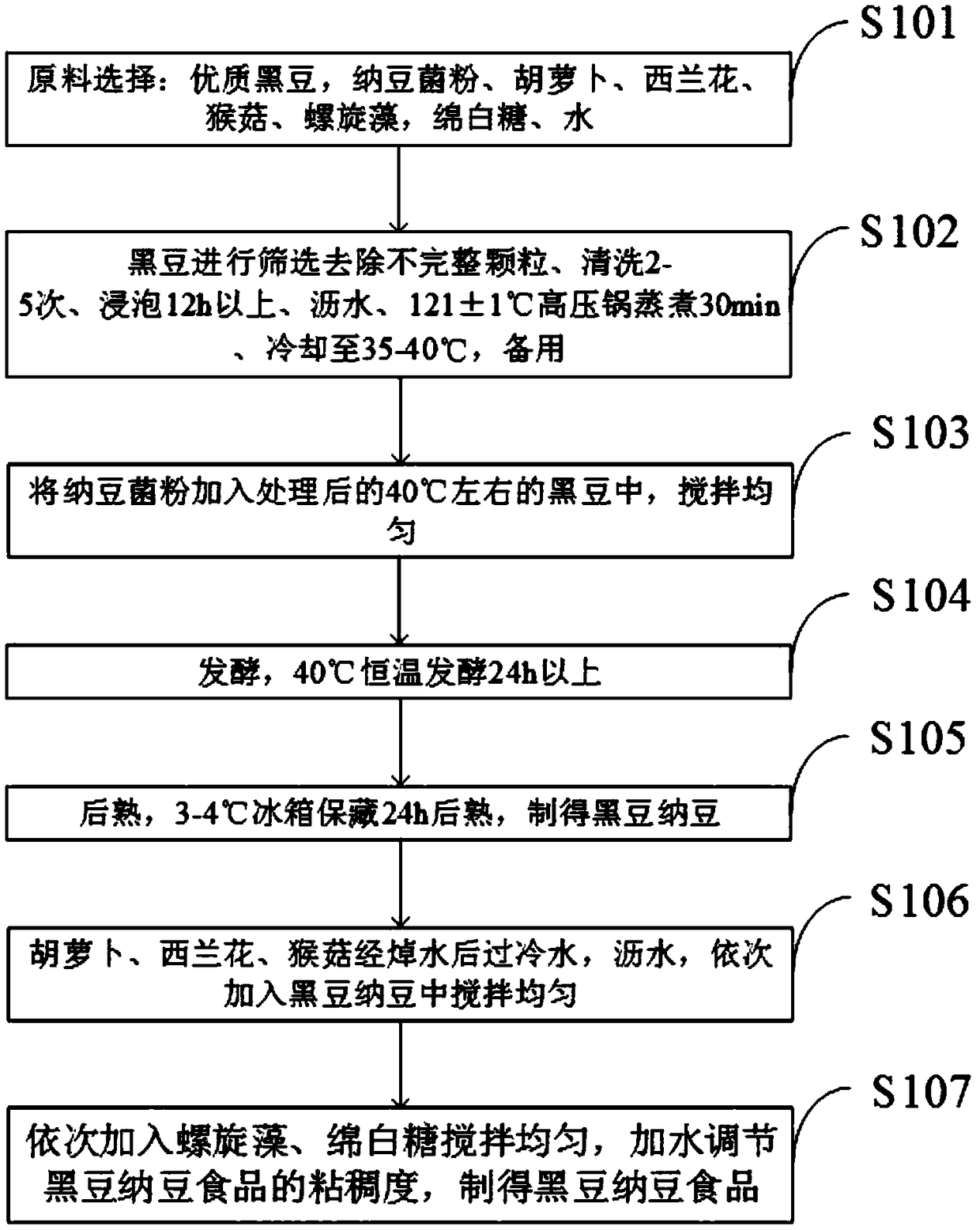

[0042] Such as figure 1 Shown, the preparation method of the black soybean natto fermented food that the embodiment of the present invention provides comprises the following steps:

[0043] S101: Raw materials: high-quality black beans, natto powder, carrots, broccoli, monkey mushrooms, spirulina, soft sugar, water;

[0044] S102: Screen the black beans to remove incomplete particles, wash 2-5 times, soak for more than 12 hours, drain, cook in a pressure cooker at 121±1°C for 30 minutes, cool to 35-40°C, and set aside;

[0045] S013: Add natto bacteria powder into the treated black beans at about 40°C, and stir evenly;

[0046] S104: fermentation, 40°C constant temperature fermentation for more than 24 hours;

[0047] S105: post-ripening, storing in a refrigerator at 3-4°C for 24 hours post-ripening to prepare black soybeans and natto;

[0048] S106: Blanch carrots, broccoli, and monkey mushrooms in cold water, drain, add black beans and natto in turn, and stir evenly;

...

Embodiment 1

[0066] The black bean and natto fermented food consists of 50 parts of black bean, 15 parts of natto bacteria powder, 5 parts of water, 10 parts of carrot, 15 parts of broccoli, 10 parts of monkey mushroom, 5 parts of spirulina and 1 part of soft white sugar.

Embodiment 2

[0068] Black soybean and natto fermented food consists of 60 parts of black soybean, 20 parts of natto bacteria powder, 10 parts of water, 15 parts of carrot, 20 parts of broccoli, 15 parts of monkey mushroom, 10 parts of spirulina, and 1-5 parts of soft white sugar composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com