Mulberry picking machine with improved structure

An improved structure and picking machine technology, which is applied to picking machines, harvesters, agricultural machinery and tools, etc., can solve the problems of cumbersome operation, unclean picking, and damage to mulberry trees, and achieve simple and efficient operation, reduced picking time, and increased The effect of picking area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

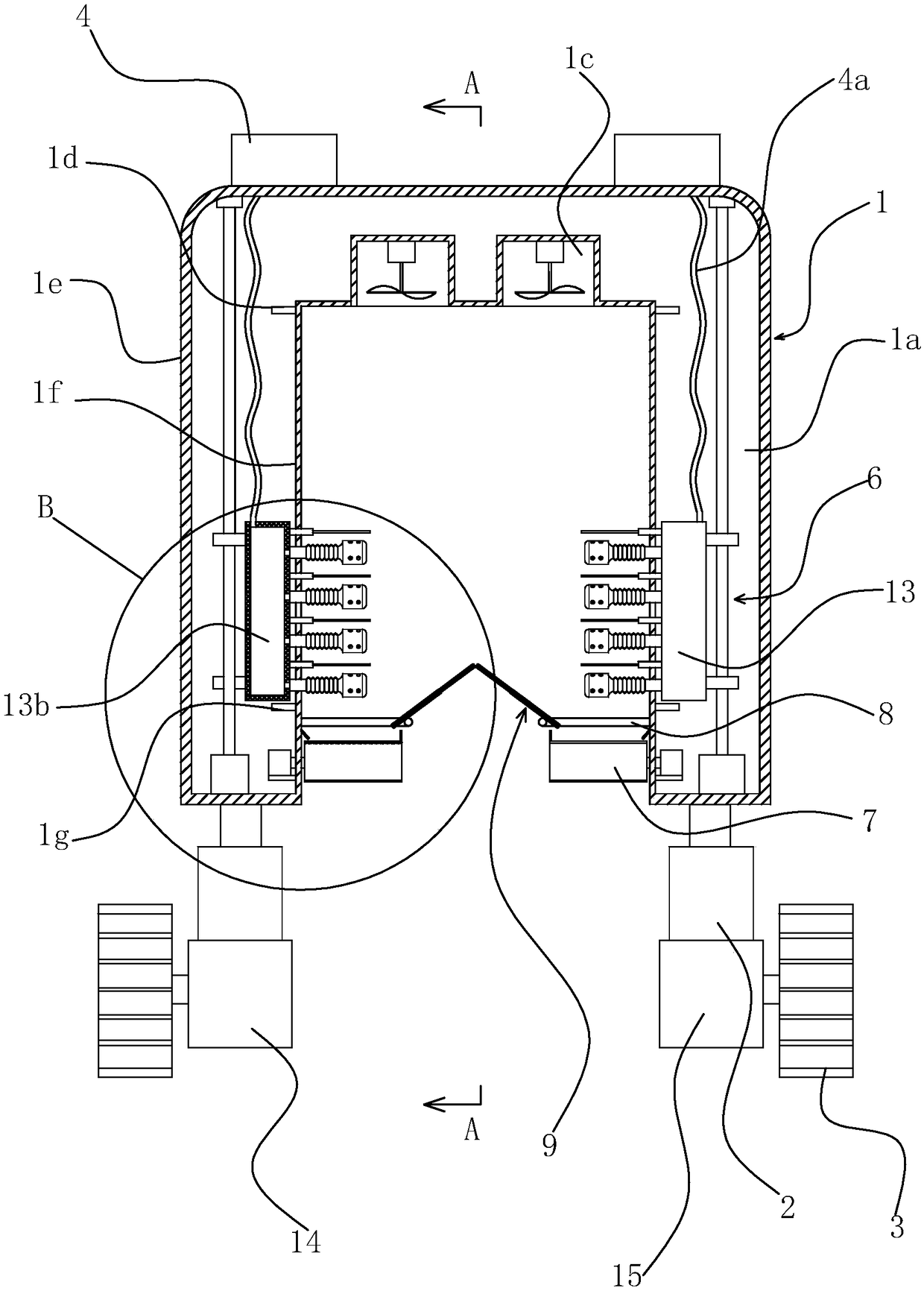

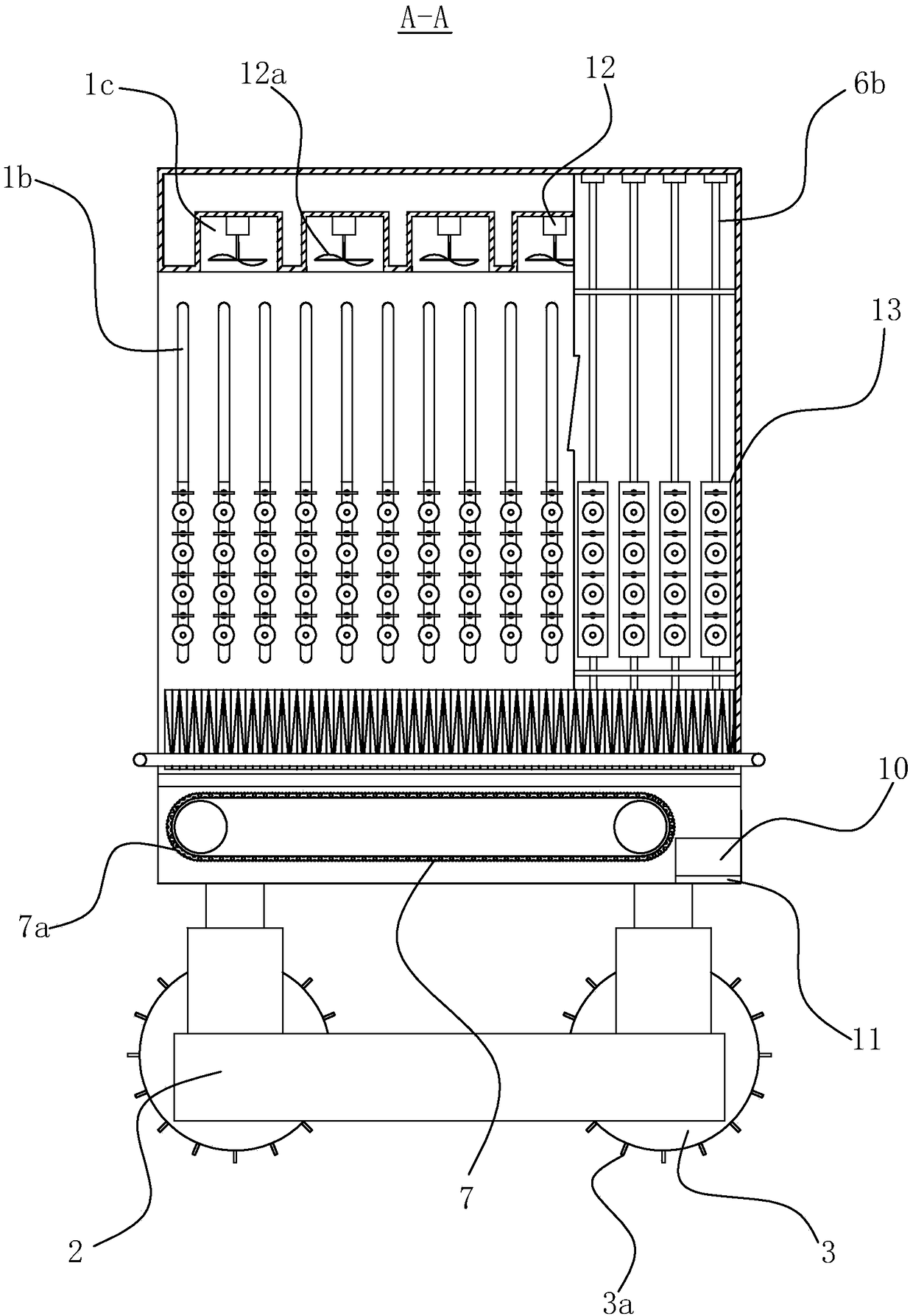

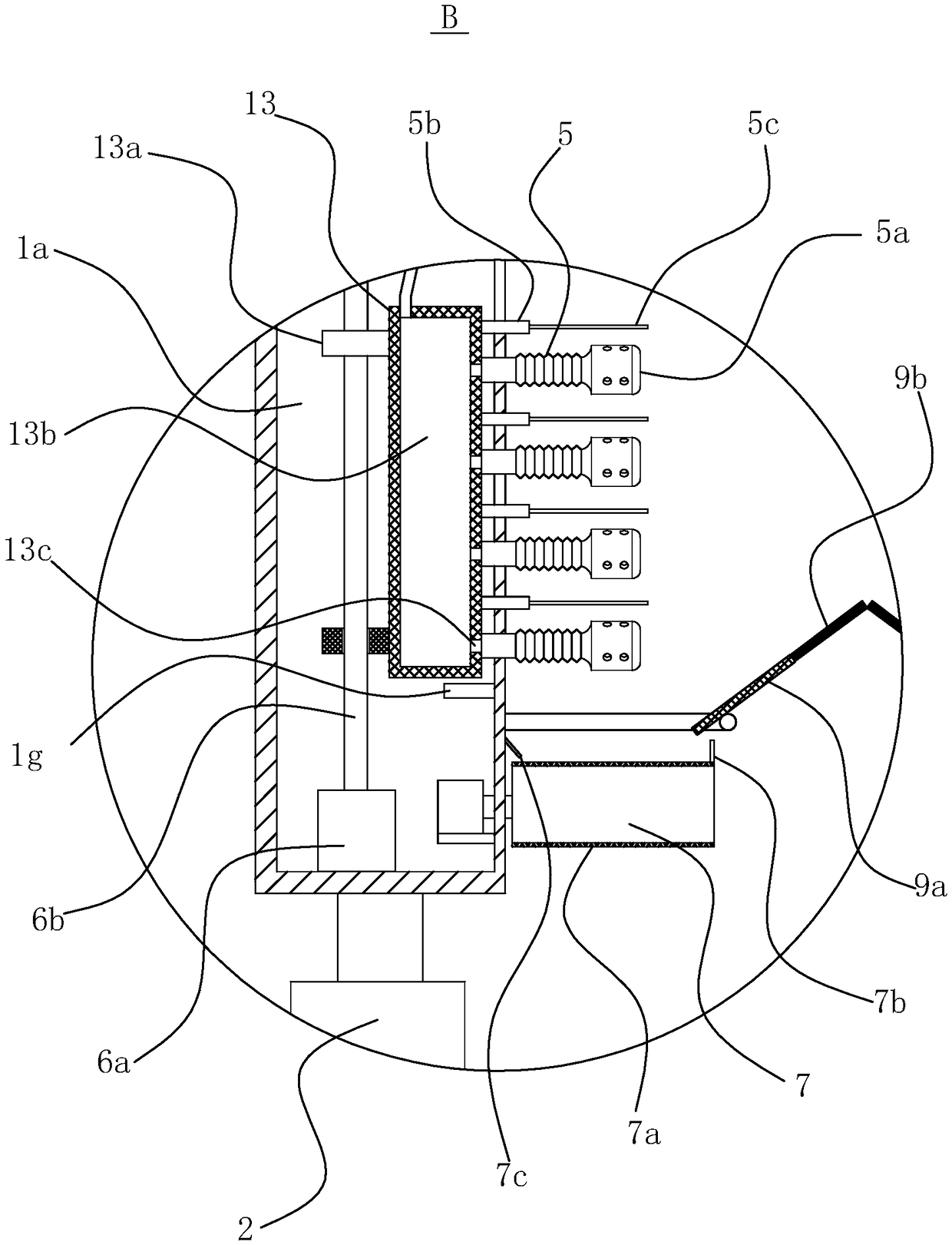

[0031] Such as Figures 1 to 3As shown, a mulberry picker of improved structure comprises a housing 1, a frame one 14 and a frame two 15 are respectively provided under the left and right sides of the housing 1, and the left side of the frame one 14 rotates Two wheels 3 are provided, and the right side of the frame two 15 is rotated to be provided with two wheels 3, the frame one 14 and the frame two 15 are provided with a driving device that can make the wheels 3 rotate, and the housing The cross section of the body 1 is an upside-down U-shape. The housing 1 includes an outer shell plate 1e and an inner shell plate 1f. The inner shell plate 1f is located inside the outer shell plate 1e. An installation cavity 1a is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com