A rapid precipitation structure and precipitation method for confined water

A pressurized water and rapid technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of engineering construction safety and construction progress, the inability to increase precipitation wells, and high cost of a single well, so as to improve construction flexibility and adjustability, reduce The effect of leaving underground obstacles and improving construction reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

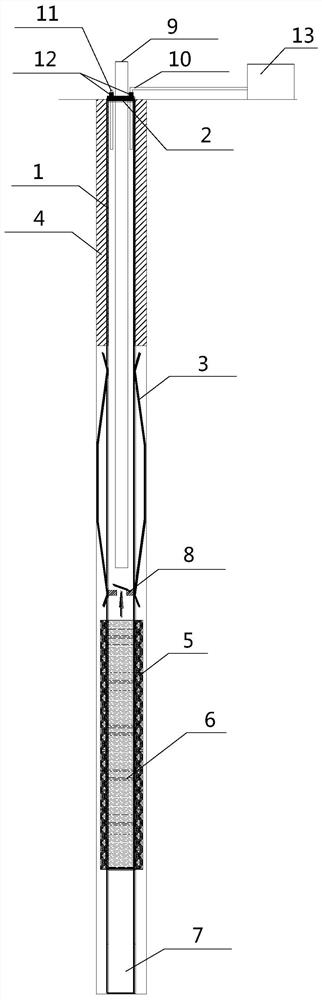

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] see figure 1 , this embodiment relates to a rapid dewatering well structure for pressurized water, which mainly includes a well pipe 1, a water-stop sealing section (the part of the sealing bag 3), a filter section (the part of the silk-wrapped filter 6), a sedimentation pipe section (the sedimentation pipe 7).

[0034] Well pipe 1, made of metal or plastic material, is connected to other parts of the well structure by welding or reliable mechanical connection;

[0035] Well pipe cover plate: the well pipe mouth is sealed at the ground end with a cover plate with openings to ensure air tightness; three openings are prefabricated on the well pipe cover plate 2, and the well pipe 1 is connected with a threaded seal;

[0036] Sealing section: the sealing bag 3 is made of high-strength tensile material. After being inserted into the well p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com