Radiation-activatable pressure-sensitive adhesive tape having a dark reaction and use thereof

A dark reaction, tape technology, applied in the field of onium-containing initiators, can solve problems affecting the properties of the final bond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

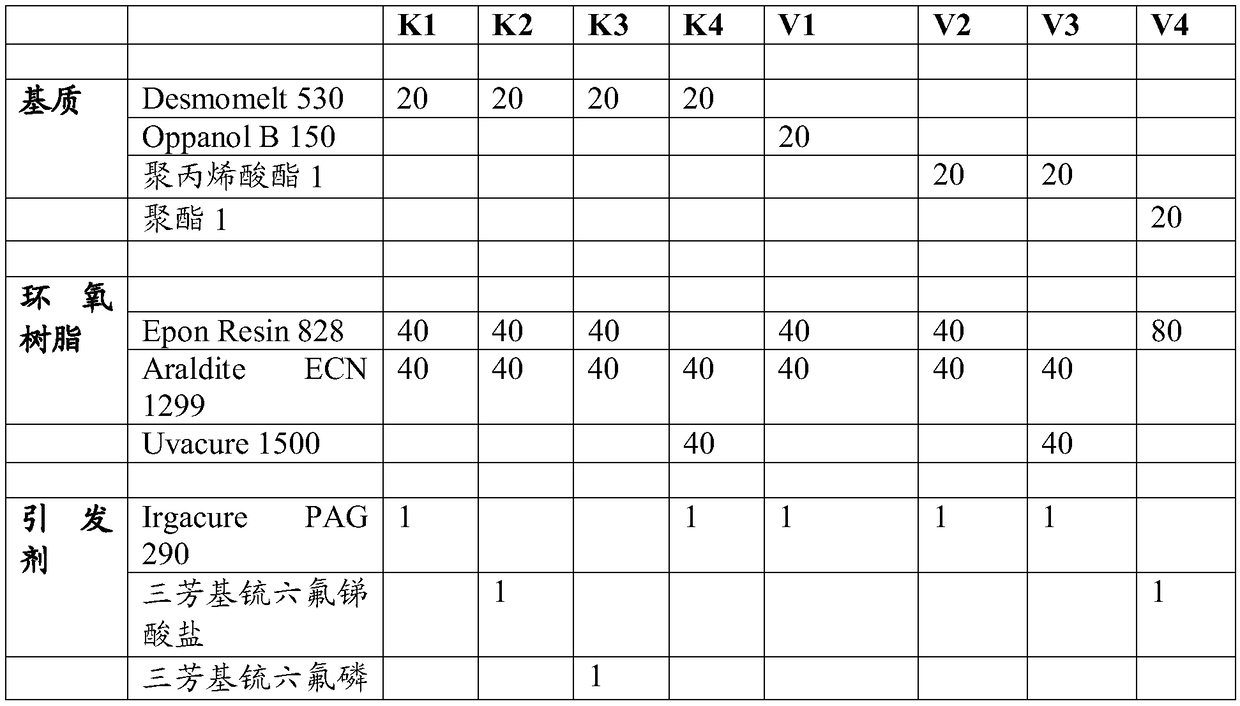

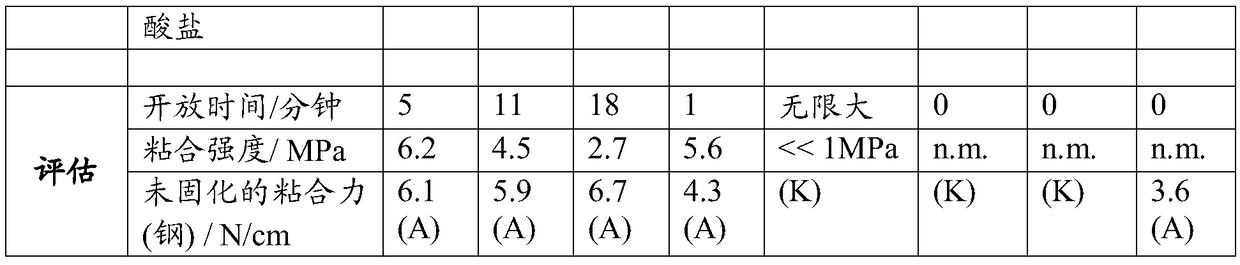

Examples

preparation example Construction

[0061] In the preparation of polyurethane polymers, the molar ratio of isocyanate groups to isocyanate-reactive groups is, for example, ≧0.90 to ≦3. In the context of the present invention, OH-functional or isocyanate-functional polyurethane polymers can be used. Functionality can be controlled by adjusting the molar ratio of isocyanate groups to isocyanate-reactive groups.

[0062]The extent of the reaction is typically monitored by tracking the NCO content of the reaction mixture. For this purpose, spectroscopic measurements, such as infrared or near-infrared spectroscopy, determination of the refractive index or chemical analyzes of the collected samples, such as titrations, can be carried out. The polyurethane polymers comprising free isocyanate groups are obtained in pure form or in solution.

[0063] In an advantageous improvement of the adhesive tape of the invention, the weight average molecular weight M of the polyurethane polymer of the film former component A w A...

Embodiment

[0181] testing method

[0182] viscosity

[0183] The fluidity of fluid coating materials is determined by dynamic viscosity. In the present case, the dynamic viscosity is determined in a cylindrical motor viscometer with standard geometry according to DIN 53019-1 (2008-09). Viscosity measured at temperature of 25°C and 1×s -1 measured at a shear rate. Fluid refers to a substance with a viscosity less than 500 Pa·s.

[0184] Molecular weight:

[0185] Number average molecular weight M n and weight average molecular weight M w The molecular weight was determined by gel permeation chromatography (GPC). The eluent used was THF (tetrahydrofuran) containing 0.1% by volume of trifluoroacetic acid. The measurement temperature was 25°C. The pre-column used was PSS-SDV, 5 μ, ID 8.0mm x 50mm. For the separation, the column used was PSS-SDV, 5μ, 10 3 and 10 5 and 10 6 , each with ID 8.0mm x 300mm. The sample concentration was 4 g / L and the flow rate was 1.0 mL per minute....

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com