Quick-change type electric automobile charging base female terminal

A technology for electric vehicles and charging stands, which is applied in the direction of circuits, electrical components, bases/housings, etc., can solve the problems of complex female terminal structures, affecting work stability, and unfavorable removal of foreign objects, and achieves convenient use and daily maintenance. Guaranteed Good electrical contact effect and good working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

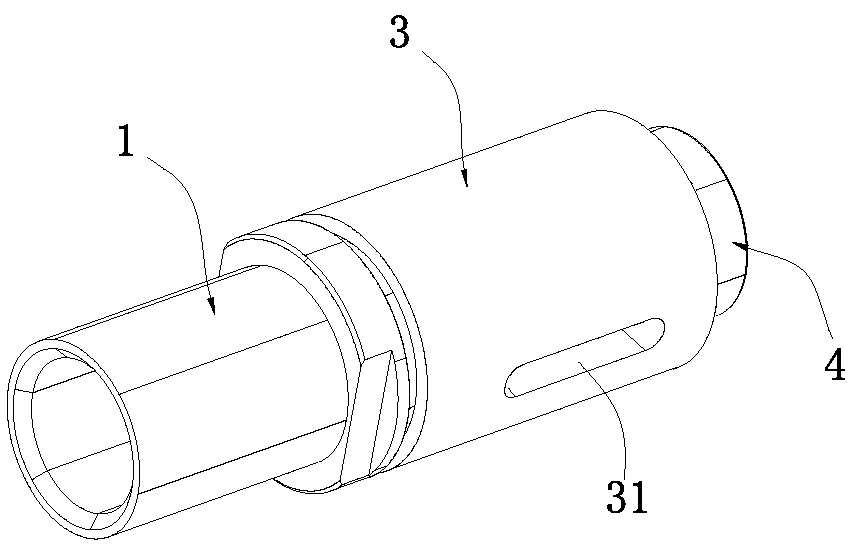

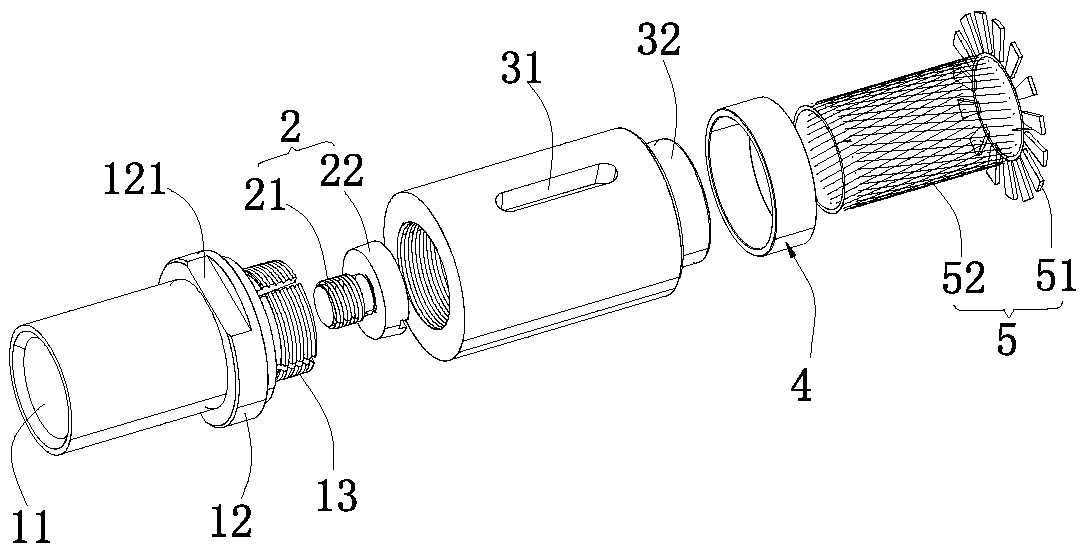

[0017] Example: see Figure 1 to Figure 3 , the present embodiment provides a quick-change electric vehicle charging seat female terminal, which includes a terminal crimping member 1 , a rotation-stopping member 2 , a female end housing 3 , a fixing sleeve 4 and a contact spring 5 .

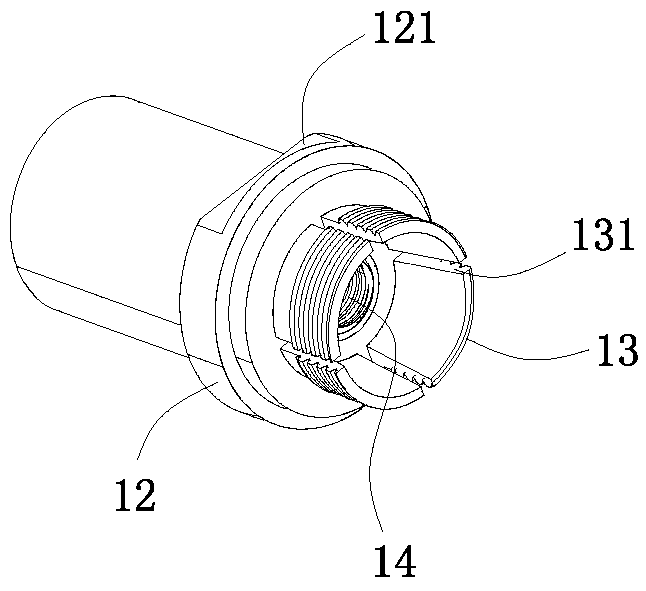

[0018] A crimping hole 11 is provided on the front surface of the terminal crimping member 1 . Preferably, a chamfer is provided on the inner edge of the opening of the crimping hole 11 , so as to facilitate quick insertion of the wire core and facilitate assembly and use. For the convenience of installation, the rear end of the terminal crimping part 1 is radially enlarged to form a mounting part 12, and a part of the outer peripheral surface of the mounting part 12 is inwardly recessed to form a clamping platform 121, which is convenient for matching with a wrench and avoids Slip phenomenon.

[0019] A sleeve 13 is provided on the rear end surface of the terminal crimping member 1 . The perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com