Fuel cell unipolar plate surface treatment method

A fuel cell and surface treatment technology, applied in the field of surface treatment, can solve the problems of high contact resistance, inability to guarantee accuracy and consistency, rough surface, etc., achieve improvement of contact resistance and flatness, good consistency of treatment effect, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

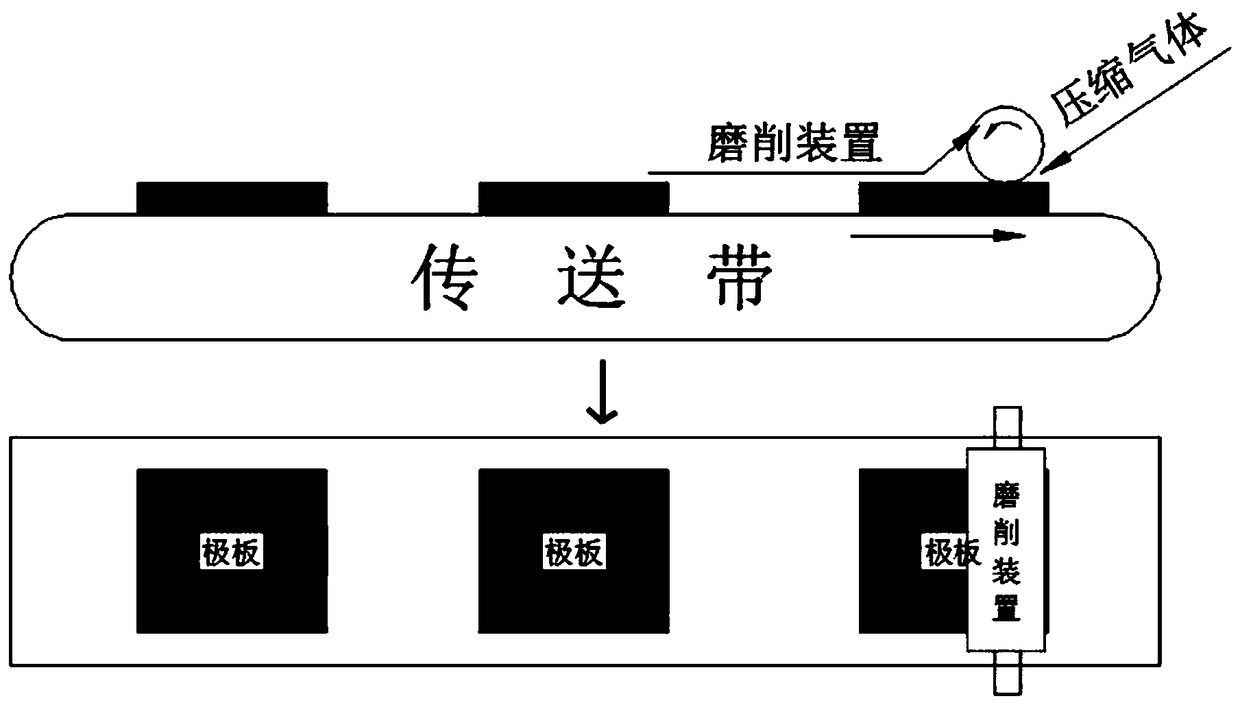

[0078] The present embodiment adopts the method for cleaning the surface by the light section method, such as figure 1 shown. Before processing, measure the conductivity, contact resistance and flatness of the plate, which are 85S / cm, 25mΩ·cm2, and 0.08mm, respectively. Ultrasonic cleaning treatment of the surface of the plate takes 1 minute, and then the conductivity, contact resistance and flatness of the treated unipolar plate are tested, and the results are 96S / cm, 20mΩ·cm2, and 0.05mm respectively. , contact resistance, and flatness have been significantly improved, and the surface treatment effect is good.

[0079] In order to confirm that the ultra-cleaning method will not introduce other impurities or cause deterioration of the board material, an X-ray energy spectrometer (EDS) is used to conduct elemental analysis on the surface before and after treatment. Since the resin in the composite plate contains O element, the change of the resin content on the surface of th...

Embodiment approach 2

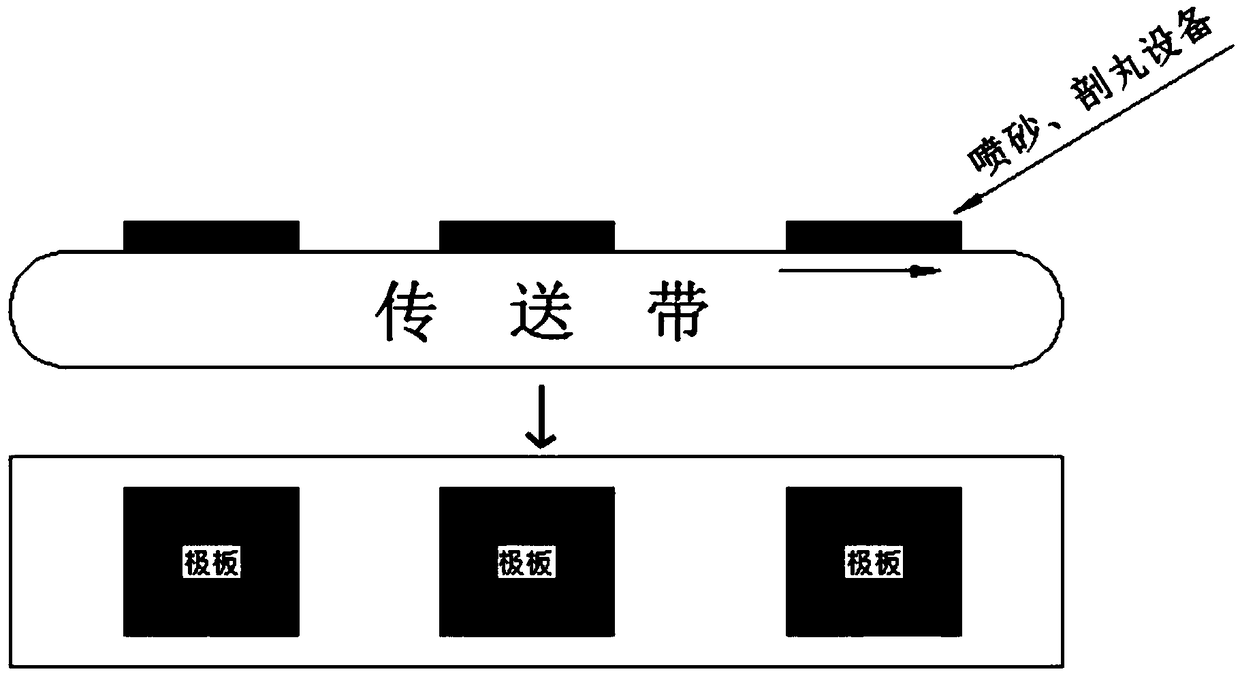

[0082] The present embodiment adopts the method for cleaning the surface by sandblasting and blasting method, such as figure 2 shown. Before processing, measure the conductivity, contact resistance and flatness of the plate, which are 85S / cm, 25mΩ·cm2, and 0.08mm, respectively. Ultrasonic cleaning treatment of the surface of the plate takes 1 minute, and then the conductivity, contact resistance and flatness of the treated unipolar plate are tested. The results are 90S / cm, 19mΩ cm2, and 0.07mm respectively. It can be found that the conductivity , contact resistance, and flatness are all improved, and the surface treatment effect is good.

[0083] In order to confirm that sand blasting and peening methods will not introduce other impurities or cause deterioration of board materials, X-ray energy spectrometer (EDS) is used to conduct elemental analysis on the surface before and after treatment. Since the resin in the composite plate contains O element, the change of the resin...

Embodiment approach 3

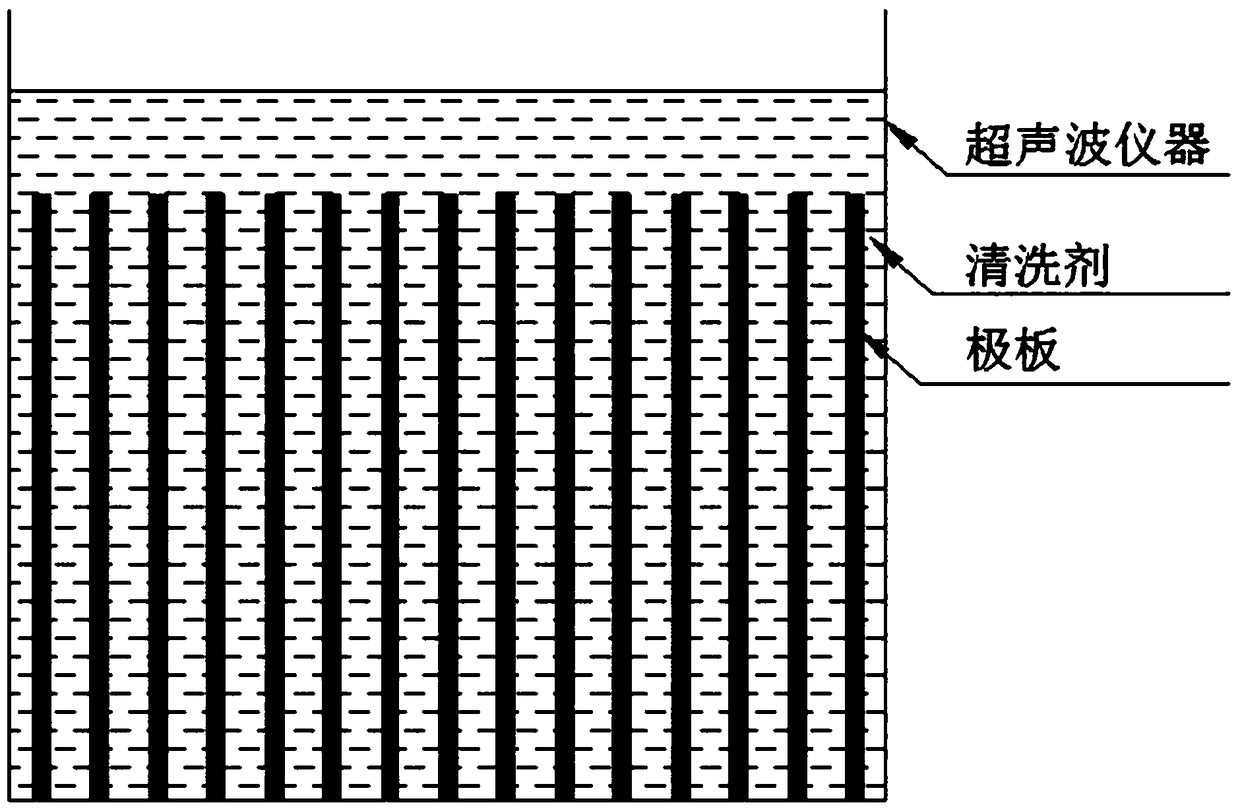

[0086] Present embodiment adopts the method for ultrasonic cleaning surface, as image 3 shown. Before processing, measure the conductivity, contact resistance and flatness of the plate, which are 85S / cm, 25mΩ·cm2, and 0.08mm, respectively. Ultrasonic cleaning treatment of the surface of the plate takes 10 minutes (the number of products processed at the same time is not less than 20 products), and then the conductivity, contact resistance and flatness of the treated unipolar plate are tested, and the results are 95S / cm and 20mΩ respectively ·cm2, 0.1mm, it can be found that the electrical conductivity and contact resistance are significantly improved, and the flatness is slightly reduced, but it meets the needs of the product and the surface treatment effect is good.

[0087] In order to confirm that the ultrasonic cleaning method will not introduce other impurities or cause the board material to deteriorate, an X-ray energy spectrometer (EDS) is used to conduct elemental an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com