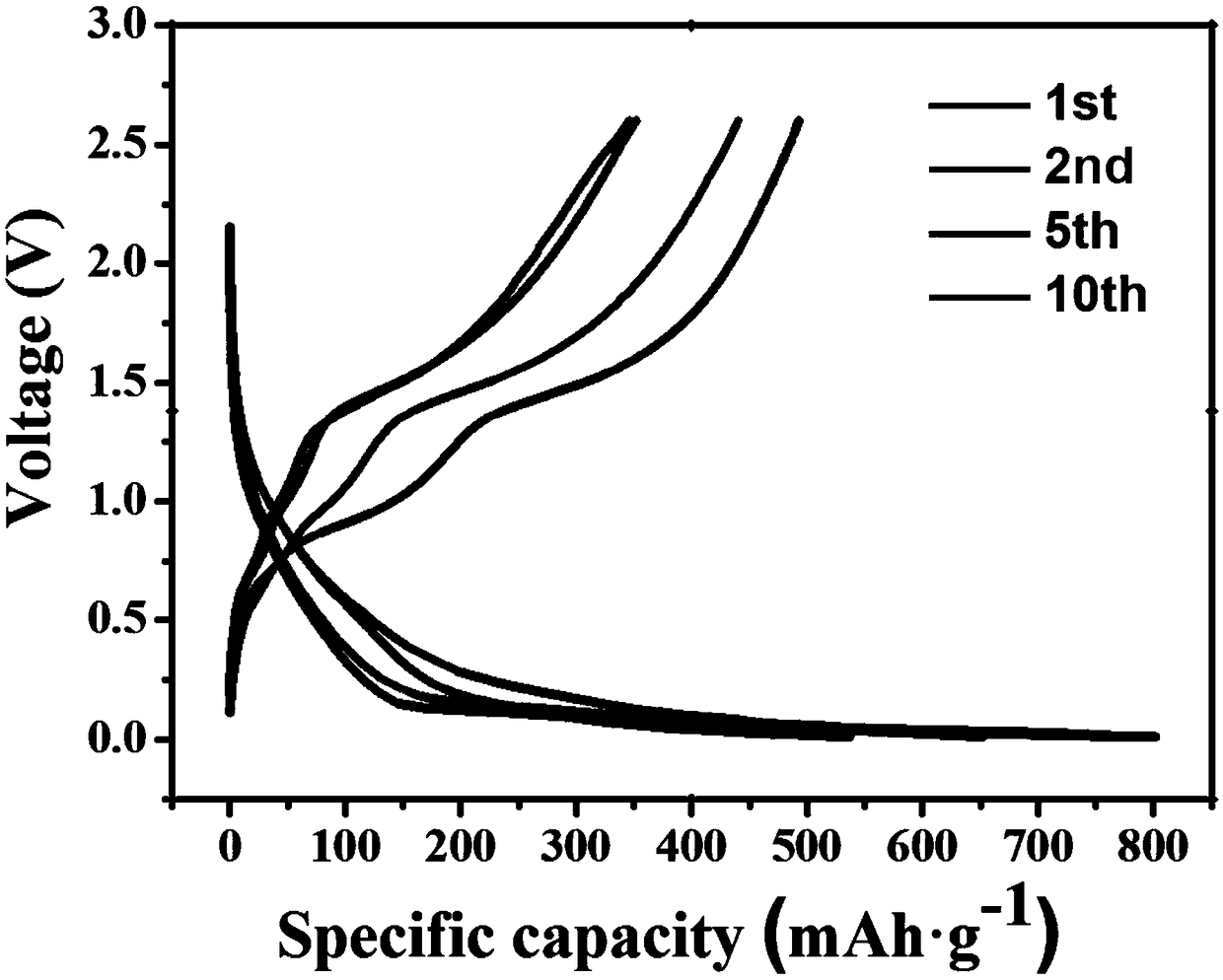

Preparation method and application of stainless steel net-loaded SnO2/SnS2 nanosheet potassium ion battery negative electrode composite material

A technology of stainless steel mesh and battery negative electrode, which is applied in the manufacture of battery electrodes, electrode carriers/current collectors, and electrolyte storage batteries. It can solve the problems of battery capacity attenuation, volume expansion and shrinkage, and achieve uniform size, simple operation, and good cycle stability. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Dissolve 1.2g of sodium hydroxide and 1.8g of tin chloride in 40ml of deionized water and fully stir to obtain solution A;

[0025] 2), transfer solution A to a stainless steel reaction kettle, and place the pre-cleaned stainless steel mesh in the solution at the same time. After reacting at 200°C for 24 hours, wash it with ethanol and deionized water for 3 times. Bake in an oven for 8 hours to obtain the precursor of carbon-coated tin oxide nanosheet structure supported by stainless steel mesh;

[0026] 3), dissolving 0.21g of thioacetamide in 30ml of deionized water, and soaking the stainless steel mesh-loaded tin oxide nanostructure obtained in 2) for 24 hours to obtain a stainless steel mesh-loaded SnO 2 / SnS 2 nanosheet structure;

[0027] 4), the assembly of the button cell will be loaded with a kind of SnO loaded on the stainless steel mesh 2 / SnS 2 The stainless steel net with nanosheet structure is punched into a disc with a diameter of 8 mm as the activ...

Embodiment 2

[0030] 1) Dissolve 1.2g of sodium hydroxide and 3.4g of tin chloride in 40ml of deionized water and fully stir to obtain solution A;

[0031] 2), transfer solution A to a stainless steel reaction kettle, and place the pre-cleaned stainless steel mesh in the solution at the same time. After reacting at 200°C for 24 hours, wash it with ethanol and deionized water for 3 times. Bake in an oven for 8 hours to obtain the precursor of carbon-coated tin oxide nanosheet structure supported by stainless steel mesh;

[0032] 3), dissolving 0.21g of thioacetamide in 30ml of deionized water, and soaking the stainless steel mesh-loaded tin oxide nanostructure obtained in 2) for 24 hours to obtain a stainless steel mesh-loaded SnO 2 / SnS 2 nanosheet structure;

[0033] 4), the assembly of the button cell will be loaded with a kind of SnO loaded on the stainless steel mesh 2 / SnS 2 The stainless steel net with nanosheet structure is punched into a disc with a diameter of 8 mm as the activ...

Embodiment 3

[0036] 1) Dissolve 1.2g of sodium hydroxide and 5.1g of tin chloride in 40ml of deionized water and fully stir to obtain solution A;

[0037] 2), transfer solution A to a stainless steel reaction kettle, and place the pre-cleaned stainless steel mesh in the solution at the same time. After reacting at 200°C for 24 hours, wash it with ethanol and deionized water for 3 times. Bake in an oven for 8 hours to obtain the precursor of carbon-coated tin oxide nanosheet structure supported by stainless steel mesh;

[0038]3), dissolving 0.21g of thioacetamide in 30ml of deionized water, and soaking the stainless steel mesh-loaded tin oxide nanostructure obtained in 2) for 24 hours to obtain a stainless steel mesh-loaded SnO 2 / SnS 2 nanosheet structure;

[0039] 4), the assembly of the button cell will be loaded with a kind of SnO loaded on the stainless steel mesh 2 / SnS 2 The stainless steel net with nanosheet structure is punched into a disc with a diameter of 8 mm as the active...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com