Sulfur-containing electrode, lithium sulfur battery containing same, and preparation method for lithium sulfur battery

A lithium-sulfur battery and electrode technology, applied in the lithium-sulfur battery containing the electrode and its preparation, and in the field of sulfur-containing electrodes, can solve the problems of reducing the energy density of lithium-sulfur batteries, poor battery safety, and piercing the isolation film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

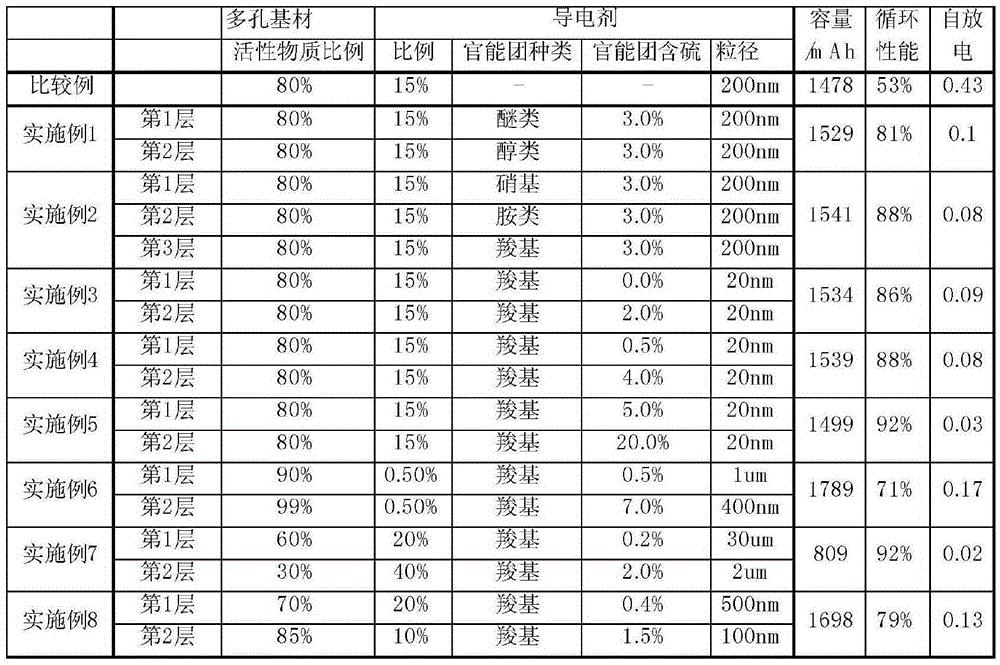

Embodiment 1

[0029] Embodiment 1, differs from comparative example in that this embodiment comprises the following steps:

[0030] Preparation of the first layer of slurry: disperse sulfur-carbon composite, conductive carbon (particle size is 200nm, containing 3% ether functional group), PVDF (sulfur-carbon composite: conductive carbon: PVDF=80:15:5) in NMP Obtain the positive electrode slurry in the stand-by;

[0031] Coating of the first layer: choose the aluminum foil as the current collector, apply the above slurry on the surface of the aluminum foil with a coating thickness of 40 μm, and dry to obtain the first layer of coating;

[0032] Preparation of the second layer of slurry: disperse sulfur-carbon composite, conductive carbon (particle size is 200nm, containing 3% alcohol functional group), PVDF (sulfur-carbon composite: conductive carbon: PVDF=80:15:5) in NMP Obtain the positive electrode slurry in the stand-by;

[0033] The second layer of coating coating: apply the above slu...

Embodiment 2

[0035] Embodiment 2, different from Embodiment 1, this embodiment includes the following steps:

[0036] Preparation of the first layer of slurry: disperse sulfur-carbon composite, conductive carbon (particle size is 200nm, containing 3% nitro functional group), PVDF (sulfur-carbon composite: conductive carbon: PVDF=80:15:5) in NMP Obtain the positive electrode slurry in the stand-by;

[0037] Coating of the first layer of coating: choose aluminum foil as the current collector, apply the above slurry on the surface of the aluminum foil, the coating thickness is 20 μm, and dry to obtain the first layer of coating;

[0038] Preparation of the second layer of slurry: disperse sulfur-carbon composite, conductive carbon (particle size is 200nm, containing 3% of amine functional groups), PVDF (sulfur-carbon composite: conductive carbon: PVDF=80:15:5) in NMP Obtain the positive electrode slurry in the stand-by;

[0039] Coating of the second layer: apply the above slurry on the sur...

Embodiment 3

[0043] Embodiment 3, different from Embodiment 1, this embodiment includes the following steps:

[0044] Preparation of the first layer of slurry: disperse sulfur-carbon composite, carbon nanotubes (diameter of 20nm, containing 0% carboxyl functional group), PVDF (sulfur-carbon composite: conductive carbon: PVDF=80:15:5) in NMP Obtain the positive electrode slurry in the stand-by;

[0045] Coating of the first layer: choose the aluminum foil as the current collector, apply the above slurry on the surface of the aluminum foil with a coating thickness of 40 μm, and dry to obtain the first layer of coating;

[0046] Preparation of the second layer of slurry: Sulfur-carbon composite, carbon nanotubes (diameter is 20nm, containing 2% carboxyl functional group), PVDF (sulfur-carbon composite: conductive carbon: PVDF=80:15:5) are dispersed in NMP Obtain the positive electrode slurry in the stand-by;

[0047] The second layer of coating coating: apply the above slurry on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com