Method for determining spandex in spandex and cellulose fiber blended knitted product

A technology of cellulose fiber and spandex fiber, which is applied in the field of analysis and testing, can solve the problems of difficulty in disassembly, damage of cellulose fiber, and low accuracy of test data, and achieve the effect of high quantitative accuracy and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

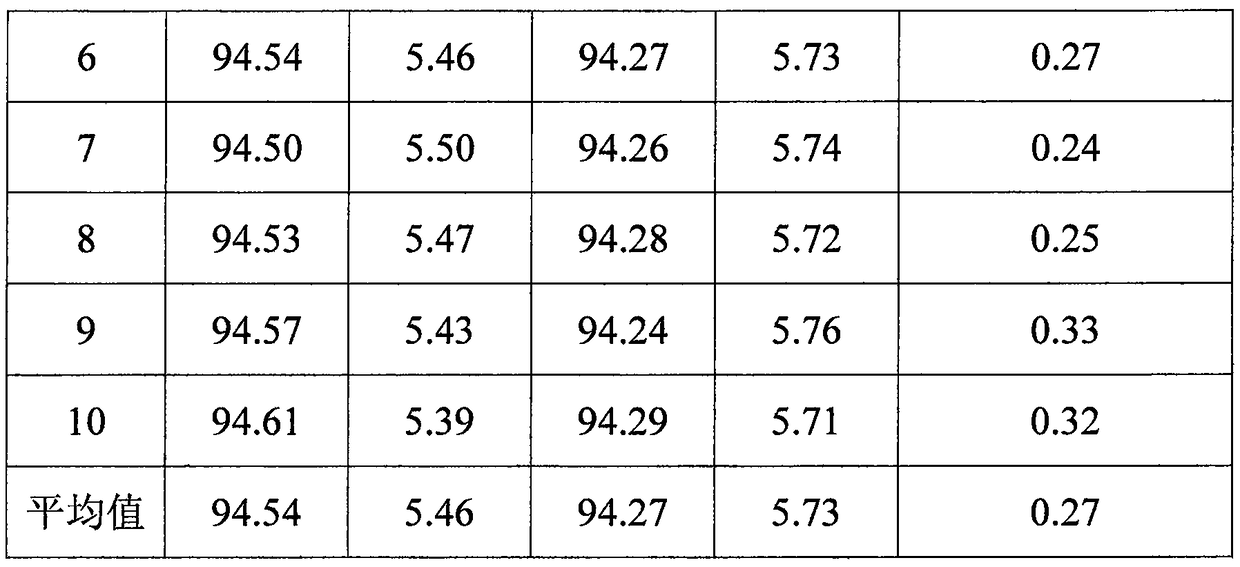

[0021] Select a whole piece of cotton / spandex blended gray knitted sample, cut 20 samples of about 1g from different parts, of which 10 samples are tested for fiber content by split method, and the remaining 10 samples are dried and weighed. After weighing, put them into 500mL glass beakers for later use. Add 200mL sodium hypochlorite solution (available chlorine concentration is 1.8mol / L) one by one, boil until boiling, filter with 80-mesh sieve, collect the residue, dry it and weigh it for calculation. The summary of 10 sets of test data is shown in Table 1:

[0022] Table 1 Comparison of fiber content results of cotton / spandex blended knitwear

[0023]

[0024]

[0025] It can be seen from the above table that the results obtained by the sodium hypochlorite solution boiling method and the split method for quantifying cotton / spandex blended products are relatively small, which is in line with the provisions of GB / T 29862-2013 "Identification of Fiber Content in Textil...

Embodiment 2

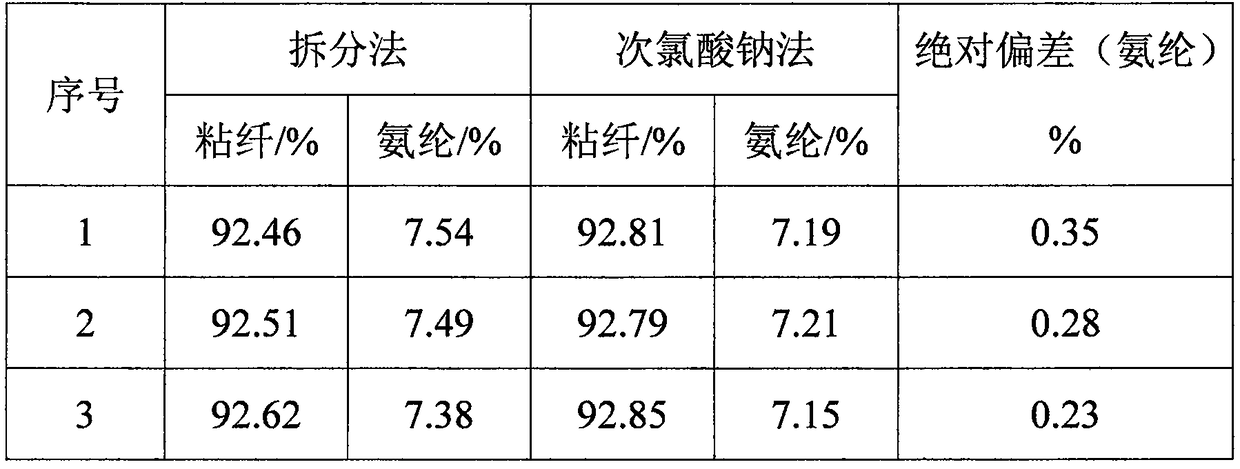

[0027] Select a whole piece of viscose / spandex blended sky blue knitted sample, cut 20 samples of about 1g from different parts, of which 10 samples are tested for fiber content by split method, and the remaining 10 samples are dried and weighed for testing. After the samples were dried, put them into 500mL glass beakers for later use. Add 200mL sodium hypochlorite solution (available chlorine concentration is 2.1mol / L) one by one, boil until boiling, filter with 80-mesh sieve, collect the residue, dry it and weigh it for calculation. The summary of 10 groups of test data is shown in Table 2:

[0028] Table 2 Comparison of fiber content results of viscose / spandex blended knitwear

[0029]

[0030]

[0031] It can be seen from the above table that there is little difference between the results obtained by the sodium hypochlorite solution boiling method and the split method for quantifying viscose / spandex blended products, which are in line with the provisions of GB / T 298...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com