Liquid nitrogen quick freeing machine for aquatic products

A freezing machine and liquid nitrogen technology, applied in the field of freezing machines, can solve the problems of unsafe, unenvironmental, and large freezing consumption of liquid ammonia, and achieve the effects of good freezing effect, short freezing time and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

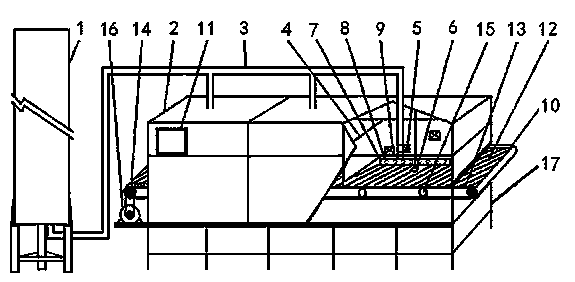

[0011] Such as figure 1 As shown, a kind of aquatic product liquid nitrogen fast freezer of the present invention is characterized in that it is made of liquid nitrogen storage tank 1, freezer casing 2, liquid nitrogen delivery pipe 3, sub-casing 4, electromagnetic valve 5, temperature probe 6, spray Nitrogen tube 7, liquid nitrogen nozzle 8, liquid nitrogen mixing motor 9, conveyor belt 10, CPU computer automatic controller 11, freezer box bracket 17; liquid nitrogen storage tank 1 is made of steel plate with a thickness of 0.8 cm and a height of 6 m , 2.5 m in diameter, liquid nitrogen storage tank 1 is a double-layer structure of inner tank and outer tank, and liquid nitrogen at -198°C is stored in the inner tank; freezer box 2 is made of stainless steel plate with a thickness of 0.02 cm and a height of 1.5 m , 2.2 m in width and 24 m in lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com